A kind of concrete thickener and preparation method thereof

A thickener and concrete technology, applied in the field of concrete thickener and its preparation, can solve the problems of reduced concrete workability, reduced concrete strength, poor compatibility of admixtures, etc. low performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

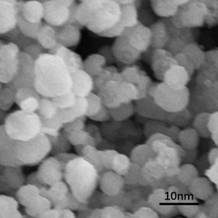

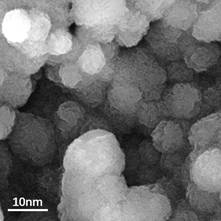

Image

Examples

Embodiment 1

[0024] This embodiment provides a concrete thickener, which is made of the raw materials of the following components in proportion by weight: nano-silica powder: 60 parts; cohesive body: 40 parts; binder: 0.3 parts; 0.5 parts of oxidizing agent; 0.3 parts of stabilizer, 0.5 parts of chain transfer agent and 100 parts of water.

[0025] The binder is ethyl cyanoacrylate.

[0026] The oxidizing agent is hydrogen peroxide.

[0027] The stabilizer is ascorbic acid.

[0028] The chain transfer agent is mercaptoethanol.

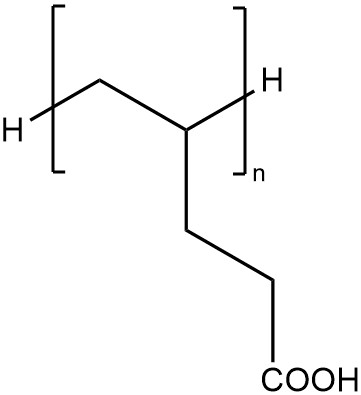

[0029] The cohesive body is 4-pentenoic acid.

Embodiment 2

[0031] This embodiment provides a concrete thickener, which is made of the raw materials of the following components in proportion by weight: nano-silica powder: 80 parts; cohesive body: 50 parts; binder: 0.6 parts; 0.8 parts of oxidizing agent; 0.3 parts of stabilizer, 0.5 parts of chain transfer agent and 110 parts of water.

[0032] The binding agent is polyacrylic acid and sodium carboxymethyl cellulose.

[0033] The oxidizing agent is hypochlorite.

[0034] The stabilizer is riboflavin.

[0035] The chain transfer agent is thioglycolic acid.

[0036] The cohesive body is 4-pentenoic acid.

Embodiment 3

[0038] This embodiment provides a concrete thickener, which is made of the raw materials of the following components in proportion by weight: nano-silica powder: 100 parts; agglomerate: 60 parts; binder: 1 part; 1 part of oxidizing agent; 0.5 part of stabilizer, 1 part of chain transfer agent and 150 parts of water.

[0039] The binder is polyacrylamide, polyacrylonitrile, styrene-butadiene rubber.

[0040] The oxidizing agent is hydrogen peroxide.

[0041] The stabilizer is riboflavin.

[0042] The chain transfer agent is mercaptoethanol.

[0043] The cohesive body is 4-pentenoic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com