In-vitro dissolution method of cross-linked sodium hyaluronate gel

A cross-linked hyaluronic acid, in vitro dissolution technology, applied in separation methods, chemical instruments and methods, filtration loops, etc., can solve the problems of uneven supernatant liquid, unable to continue enzymatic hydrolysis, etc., and achieve the effect of uniform liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

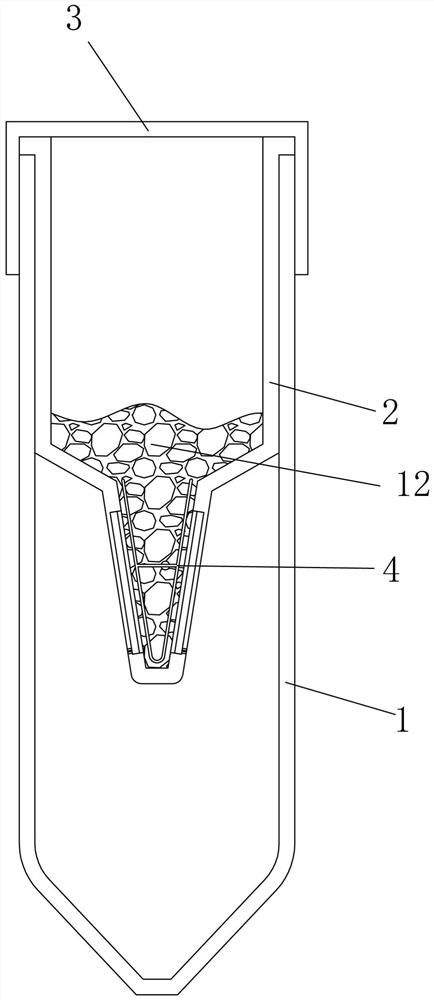

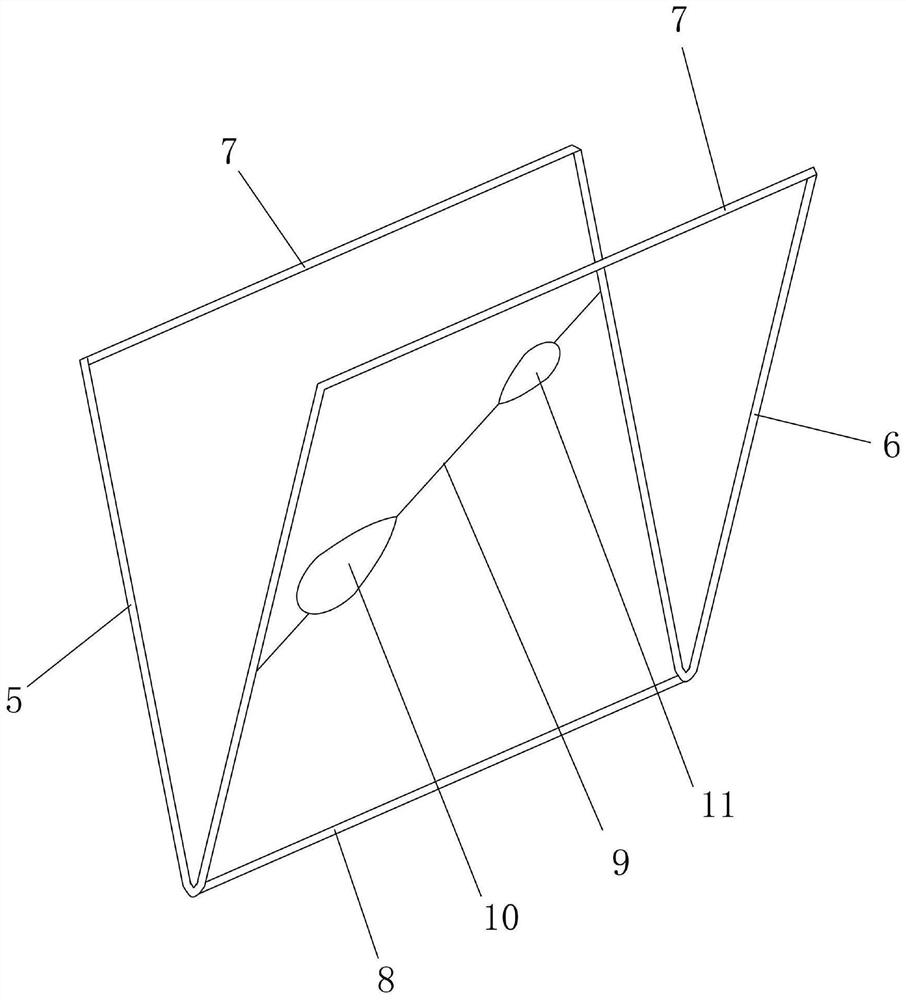

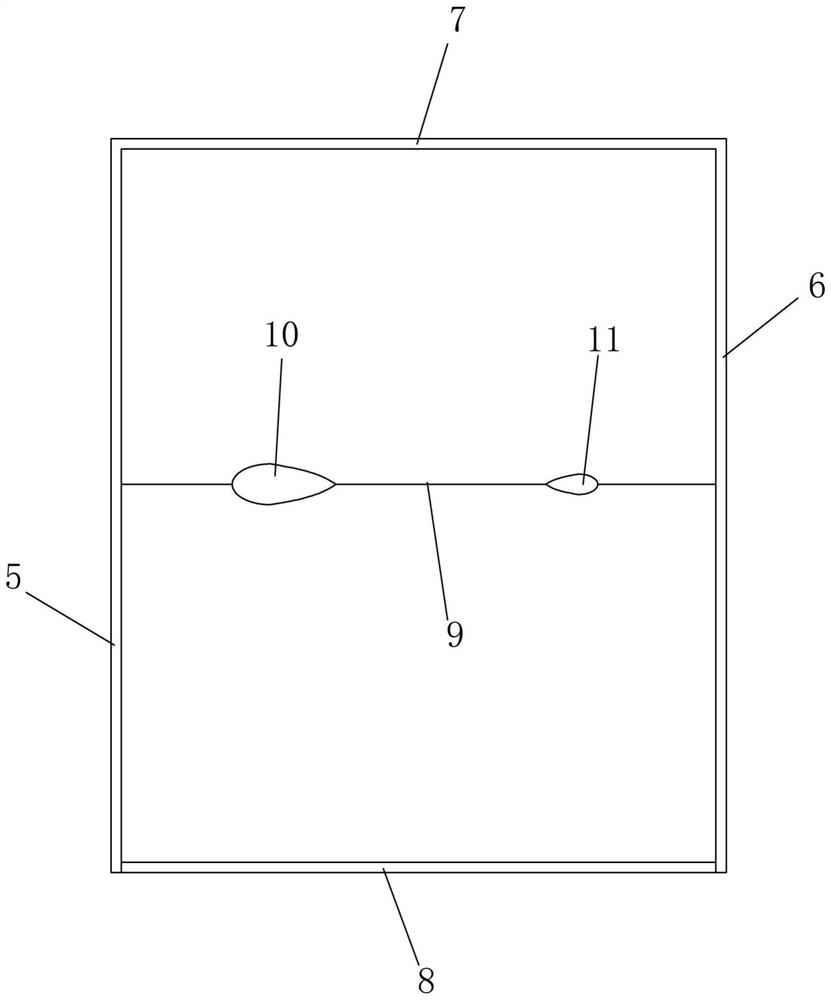

[0020] Embodiment: a kind of in vitro dissolution method of cross-linked sodium hyaluronate gel, such as Figure 1-Figure 3 As shown, the in vitro dissolution method comprises the following steps:

[0021] Step A, prepare cross-linked sodium hyaluronate gel, Amicon Ultra-15 tube, constant temperature shaker and centrifuge;

[0022] Step B. Weigh 5g of cross-linked sodium hyaluronate gel, open the lid of the Amicon Ultra-15 tube, and put 5g of cross-linked sodium hyaluronate gel into the inner filter tube of the Amicon Ultra-15 tube. Put the resonator in the layer filter tube, the position of the resonator is the bottom of the inner layer filter tube of the Amicon Ultra-15 tube, tighten the cover and put it into the constant temperature oscillator, set the temperature to 36.0°C, and the speed to 150r / min, Stop oscillation after 24h;

[0023] Step C. After step B, take the Amicon Ultra-15 tube out of the temperature shaker, and then put it into 37°C constant temperature water;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com