High light transmittance, super tough, heat/solvent responsive repair polyurethane and preparation method thereof

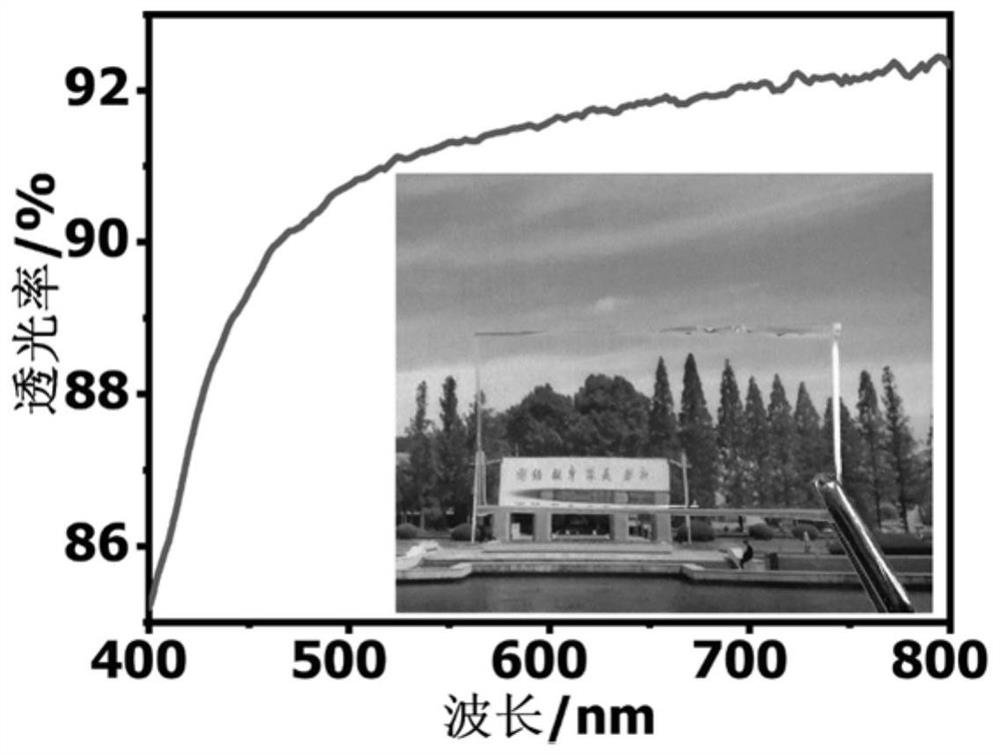

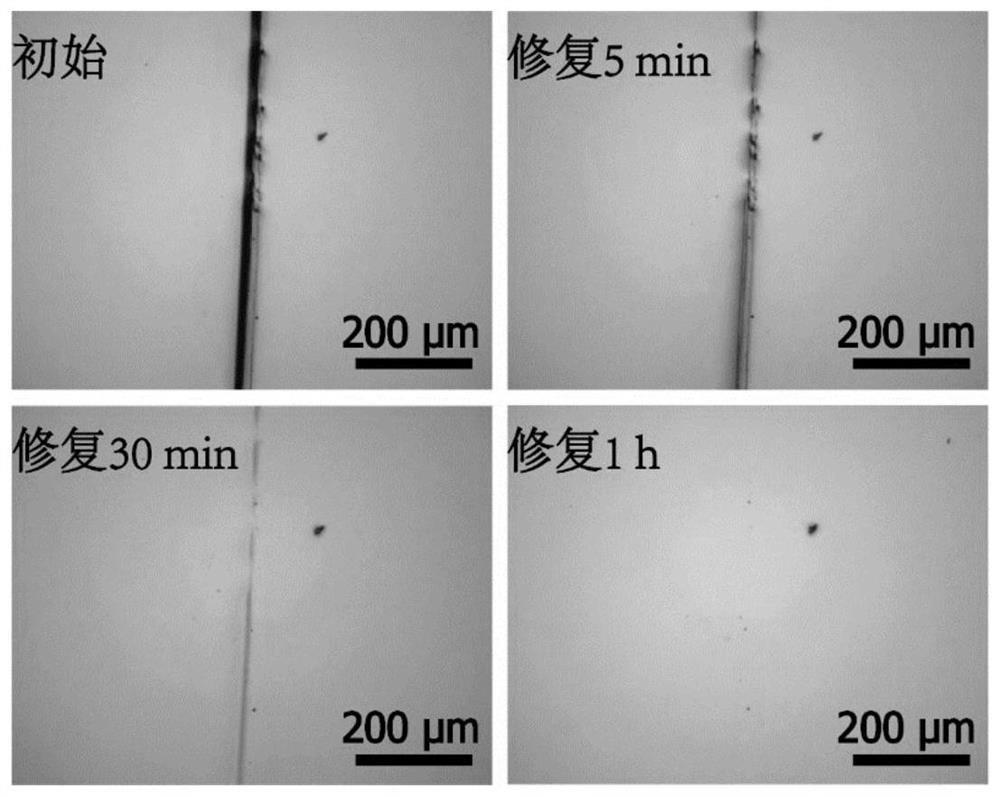

A technology with high light transmittance and solvent response, applied in the field of self-healing materials, can solve the problems that it is difficult to take into account the mechanical properties and self-healing effects, it is difficult for self-healing materials to achieve self-healing at room temperature, and the practical application and promotion are limited. Good water vapor adsorption resistance, excellent self-healing ability, and stable repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

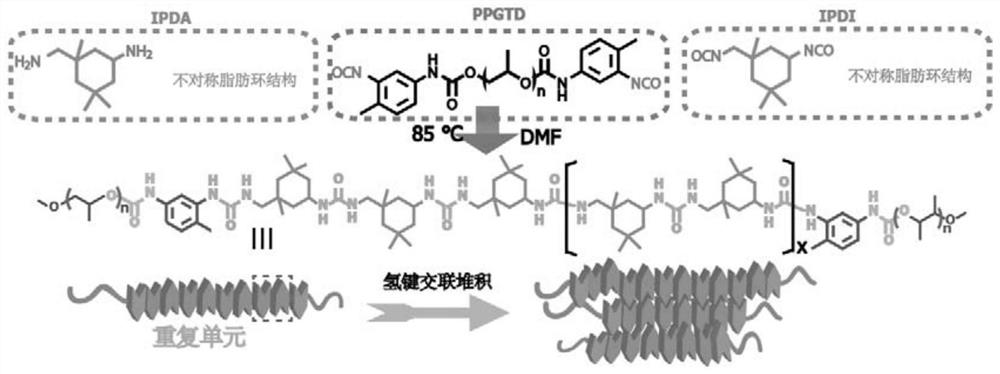

Method used

Image

Examples

Embodiment 1

[0050] The preparation method of high light transmittance super strong super tough heat / solvent responsive repair polyurethane, the specific steps are as follows:

[0051] a. Under an inert gas atmosphere, dissolve 6.900 g of toluene diisocyanate-terminated polypropylene glycol (molecular weight: 2300) and 1.000 g of isophorone diisocyanate in 20 mL of N,N'-dimethylformamide solvent to prepare Mixed solution I;

[0052] b. Dissolve 1.280 g of isophorone diamine in 10 mL of N,N'-dimethylformamide solvent to prepare mixed solution II, and then add mixed solution II dropwise to step a at 0-4°C In the obtained mixed solution I, the dropping rate was 1000 μL / min, and the reaction was stirred for 9 to 12 h to obtain the initial product solution III, in which the sum of the molar amounts of toluene diisocyanate-terminated polypropylene glycol and isophorone diisocyanate and isofluoride The molar ratio of ketone diamine is 100:100;

[0053] c. heating the initial reaction product so...

Embodiment 2

[0057] The preparation method of high light transmittance super strong super tough heat / solvent responsive repair polyurethane, the specific steps are as follows:

[0058] a. Under an inert gas atmosphere, dissolve 6.900 g of toluene diisocyanate-terminated polypropylene glycol (molecular weight: 2300) and 1.556 g of isophorone diisocyanate in 20 mL of N,N'-dimethylformamide solvent to prepare Mixed solution I;

[0059] b. Dissolve 1.703 g of isophorone diamine in 10 mL of N,N'-dimethylformamide solvent to prepare mixed solution II, and then add mixed solution II dropwise to step a at 0-4°C In the obtained mixed solution I, the dropping rate was 1000 μL / min, and the reaction was stirred for 9 to 12 h to obtain the initial product solution III, in which the sum of the molar amounts of toluene diisocyanate-terminated polypropylene glycol and isophorone diisocyanate and isofluoride The molar ratio of ketone diamine is 100:100;

[0060] c. heating the initial reaction product so...

Embodiment 3

[0064] The preparation method of high light transmittance super strong super tough heat / solvent responsive repair polyurethane, the specific steps are as follows:

[0065] a. Under an inert gas atmosphere, dissolve 6.900 g of toluene diisocyanate-terminated polypropylene glycol (molecular weight: 2300) and 0.667 g of isophorone diisocyanate in 20 mL of N,N'-dimethylformamide solvent to prepare Mixed solution I;

[0066] b. Dissolve 1.022 g of isophorone diamine in 10 mL of N,N'-dimethylformamide solvent to prepare mixed solution II, and then add mixed solution II dropwise to step a at 0 to 4°C In the obtained mixed solution I, the dropping rate was 1000 μL / min, and the reaction was stirred for 9 to 12 h to obtain the initial product solution III, in which the sum of the molar amounts of toluene diisocyanate-terminated polypropylene glycol and isophorone diisocyanate and isofluoride The molar ratio of ketone diamine is 100:100;

[0067] c. heating the initial reaction product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| toughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com