Special-shaped column and I-shaped steel beam connecting joint structure and joint safety monitoring method

A technology for connecting nodes and I-beams, applied in building components, measuring devices, instruments, etc., can solve problems such as hidden safety hazards, no real-time observation of deformation degree and alarm, damage to components at node connections, etc. The use of bolts, the avoidance of personal and property damage, the effect of strong bearing capacity and shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

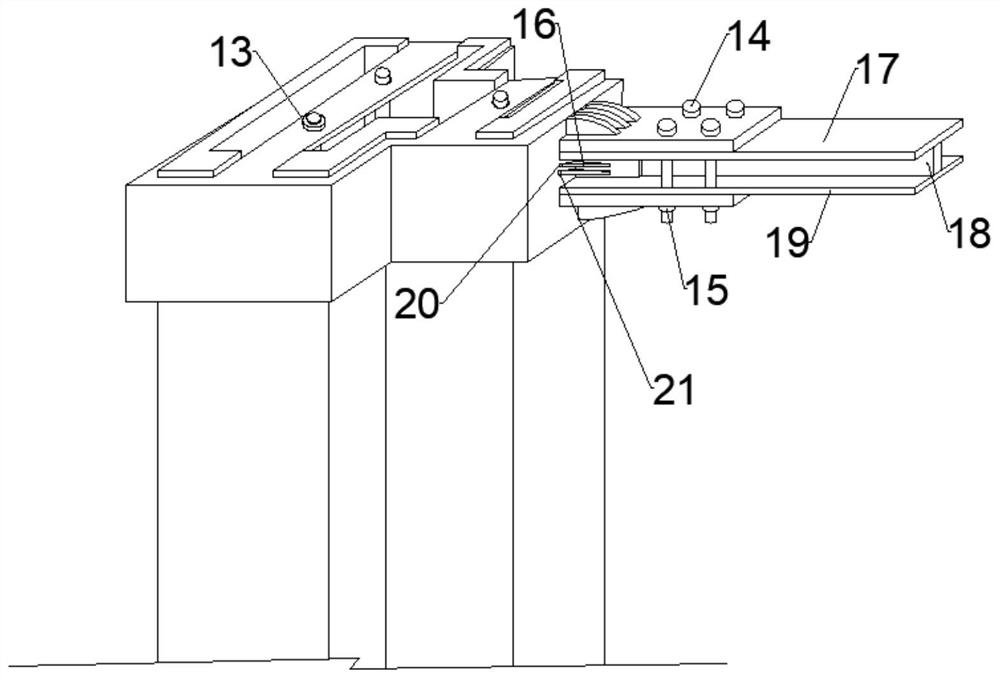

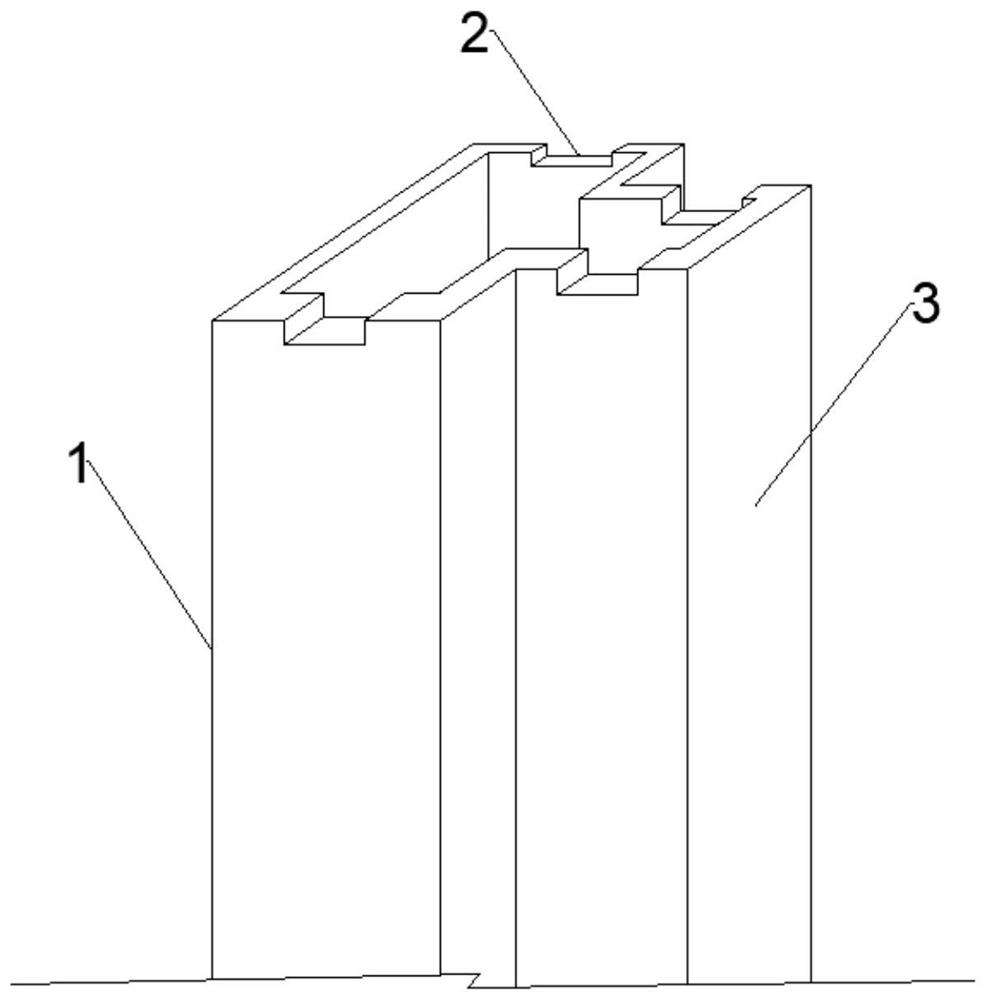

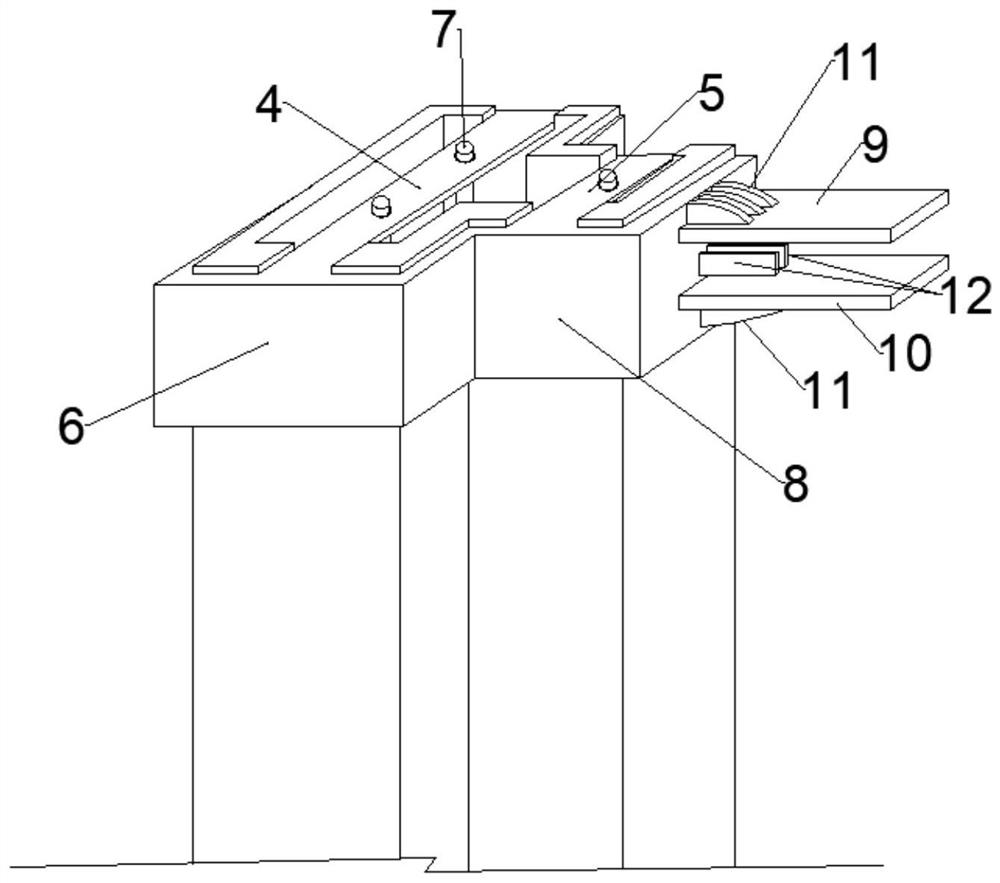

[0035] A connection node structure between concrete filled steel pipe special-shaped columns and I-shaped steel beams, such as figure 2 , 3 As shown, it includes a core special-shaped column 1, a transfer structure, and an I-shaped steel beam. Concrete is poured in the core special-shaped column 1, and a card slot 2 is provided at the top of the side wall of the core special-shaped column 1. One end of the connection structure is clamped on the top of the core special-shaped column, and the other end is detachably and fixedly connected to the end of the I-beam. The concrete is provided with prestressed steel bars 7, and the transfer structure is passed through the prestressed steel bars. 7 fixed along the longitudinal direction;

[0036] Such as figure 2 , 3As shown, the cross-section of the core special-shaped column 1 is a "T"-shaped structure, and the left end of the "T"-shaped structure and the top of the side wall of the protruding end 3 protruding to the right along...

Embodiment 2

[0043] Such as figure 1 , 3 As shown, the vertical plates 12 are made of low-carbon steel, and two extruded plates 16 arranged in parallel up and down are respectively connected to the outer end surfaces of the two vertical plates 12, and the left ends of the extruded plates 16 protrude from the The right end surface of the end fastening plate 8 is clearance fit;

[0044] Such as figure 1 , 4 As shown, a first pressure sensor 20, a second pressure sensor 21, a third pressure sensor 22, and a fourth pressure sensor 23 are respectively provided on the right end surface of the protruding end fastening plate 8 opposite to the left end of the extrusion plate 16, The first pressure sensor 20, the second pressure sensor 21, the third pressure sensor 22, and the fourth pressure sensor 23 are electrically connected to a power supply, a display and an alarm by wires respectively. The third pressure sensor 22 is located at the top, and the second pressure sensor 21 and the fourth pre...

Embodiment 3

[0046] Such as figure 1 , 4 As shown, a method for monitoring and judging the safety status of the joint structure of the special-shaped steel pipe concrete column and the I-shaped steel beam connection structure, including:

[0047] A. When the first pressure sensor 20 and the third pressure sensor display the pressure value, while the pressure value of the fourth pressure sensor and the second pressure sensor 21 is 0, it means that the right end of the I-beam is upturned; otherwise, it means the I-shaped The right end of the steel beam droops.

[0048] B. When the first pressure sensor 20 and the second pressure sensor 21 display the pressure value, and the pressure value of the third pressure sensor and the fourth pressure sensor is 0, it means that the right end of the I-shaped steel beam is convex; otherwise, it represents the I-shaped The right end of the steel beam is kyphotic.

[0049] C. If the value of a certain pressure sensor is obviously greater than the value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com