SCR system NOx generation and ammonia demand prediction method and system and storage medium

A technology of SCR system and demand forecasting, which is applied in the direction of machine/engine, mechanical equipment, design optimization/simulation, etc., and can solve the problems of poor follow-up of urea hydrolysis system under changing working conditions, unstable automatic operation of ammonia injection, and large delay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

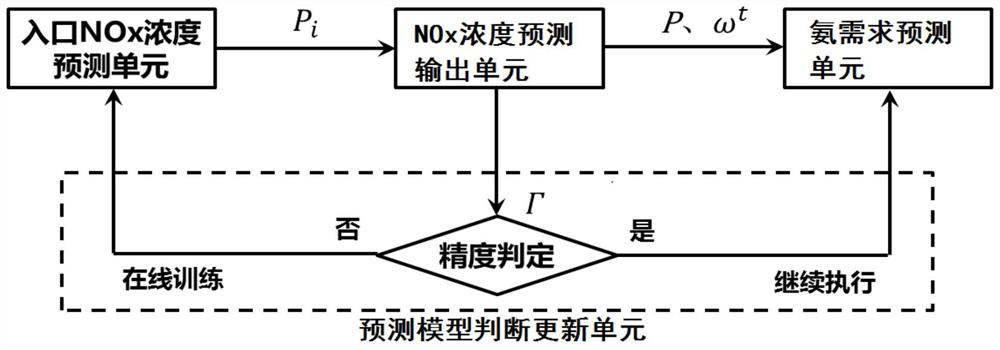

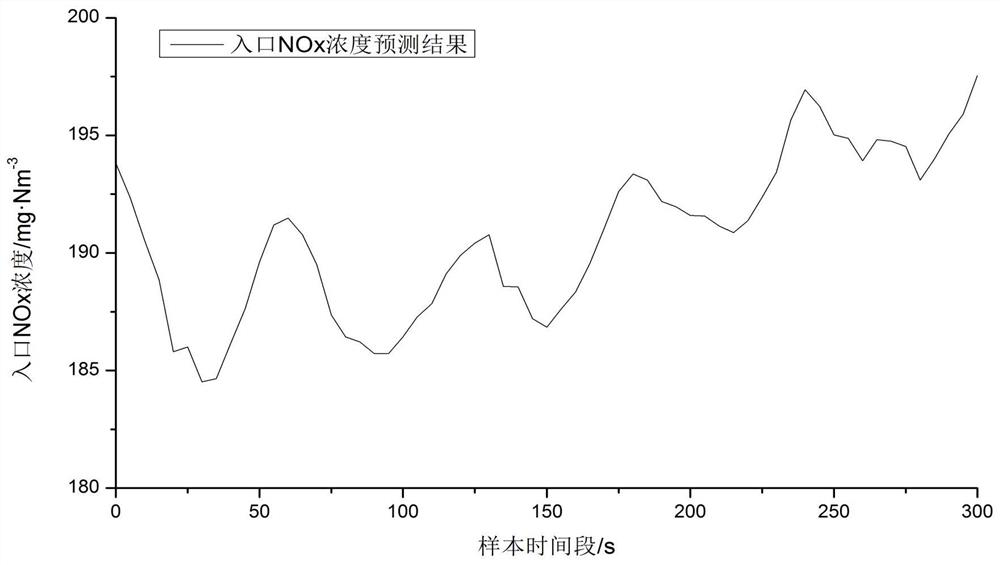

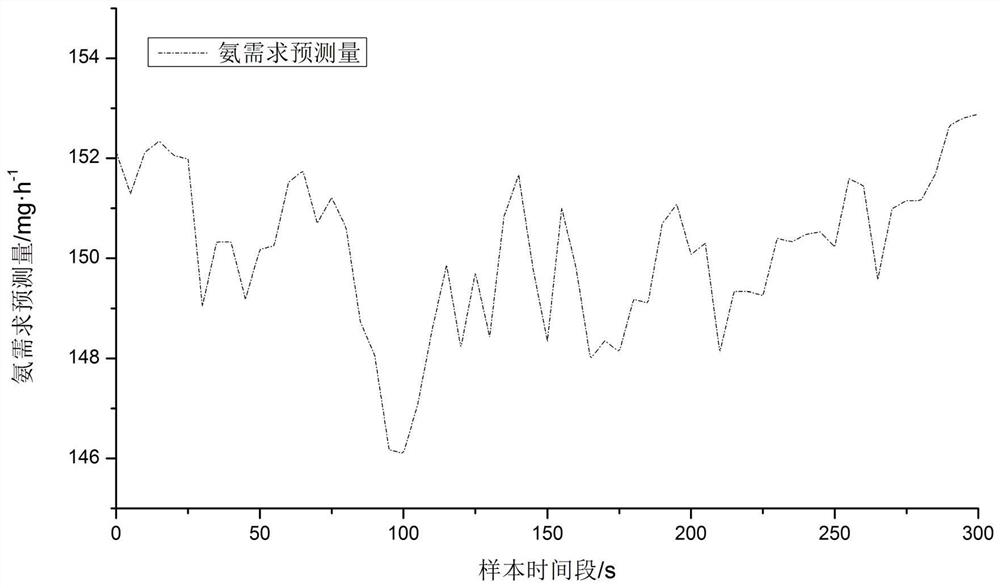

[0042] Under the background of vigorously promoting the conversion of liquid ammonia to urea in the SCR system of coal-fired power stations, and the increasingly frequent operation of variable operating conditions such as large-scale peak-shaving of coal-fired power stations, the present invention provides a method, system and storage medium for predicting NOx generation and ammonia demand in SCR systems , can improve the variable working condition follow-up characteristics of the urea hydrolysis system, and realize the precise ammonia injection of the SCR system of the coal-fired power station. The present invention will be further described below in conjunction with the accompanying drawings.

[0043] The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention. Those skilled in the art should understand that the embodiments of the present application may be pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com