Ammonia injection grid for SCR denitration system

An ammonia injection grid and denitration technology, which is applied in the field of ammonia injection grid, can solve the problems of increasing the contact area of flue gas, increasing the mixing time of ammonia flow and flue gas, and uneven distribution of ammonia gas, so as to reduce the by-products of ammonia injection. The generation of NOx, reducing the operating cost of denitration, and the effect of uniform NOX reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

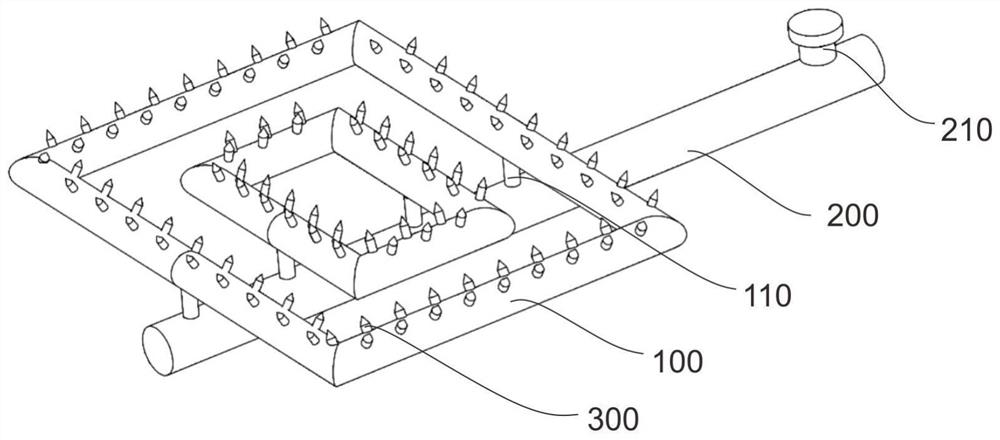

[0034] refer to figure 1, which is the first embodiment of the present invention, this embodiment provides an ammonia injection grid for SCR denitrification system, the ammonia injection grid for SCR denitrification system includes branch pipe assembly 100 and branch pipe assembly 200, wherein the branch pipe assembly 100 is arranged on the main pipe assembly 200 below the branch pipe assembly 100 through the connecting pipe 110. One end of the main pipe assembly 200 is provided with a control valve 210, and the branch pipe assembly 100 is arranged in a "back" shape;

[0035] The branch pipe assemblies 300 are evenly spaced and distributed on the upper surface of the branch pipe assembly 100 in a cross-staggered manner, and are arranged in high and low layers.

[0036] Based on the above, the branch pipe assembly 100 is arranged in a "back" shape, and the connecting pipe 110 is arranged vertically below the pipe branch assembly 100. The number of connecting pipes 110 is prefer...

Embodiment 2

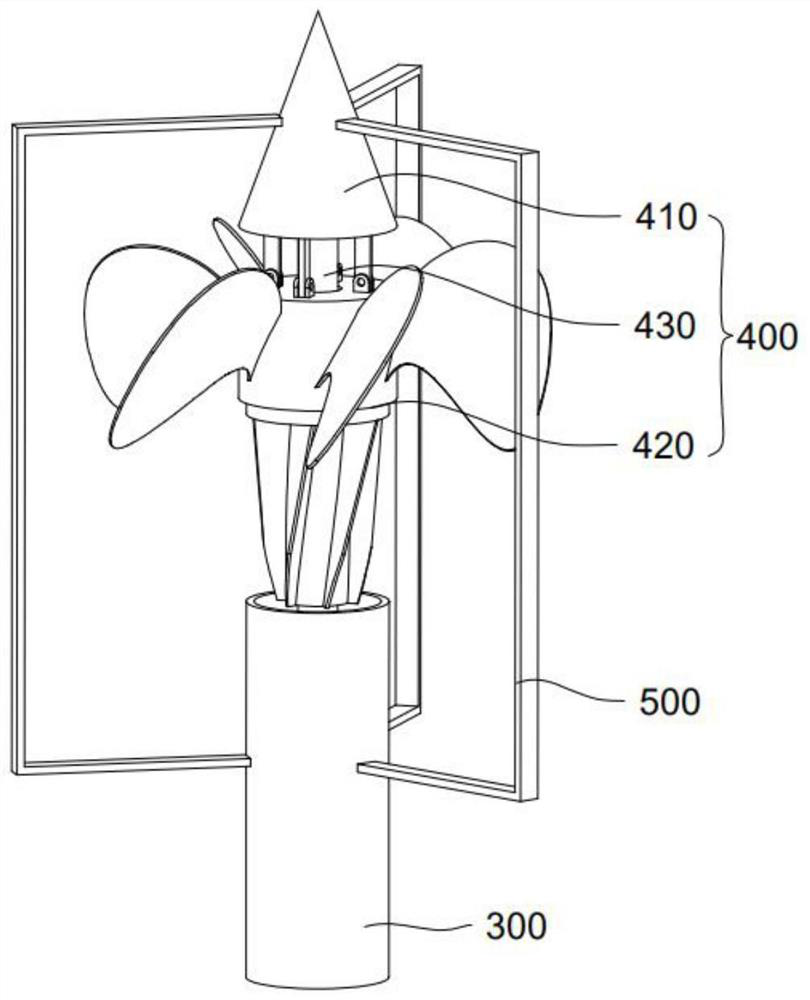

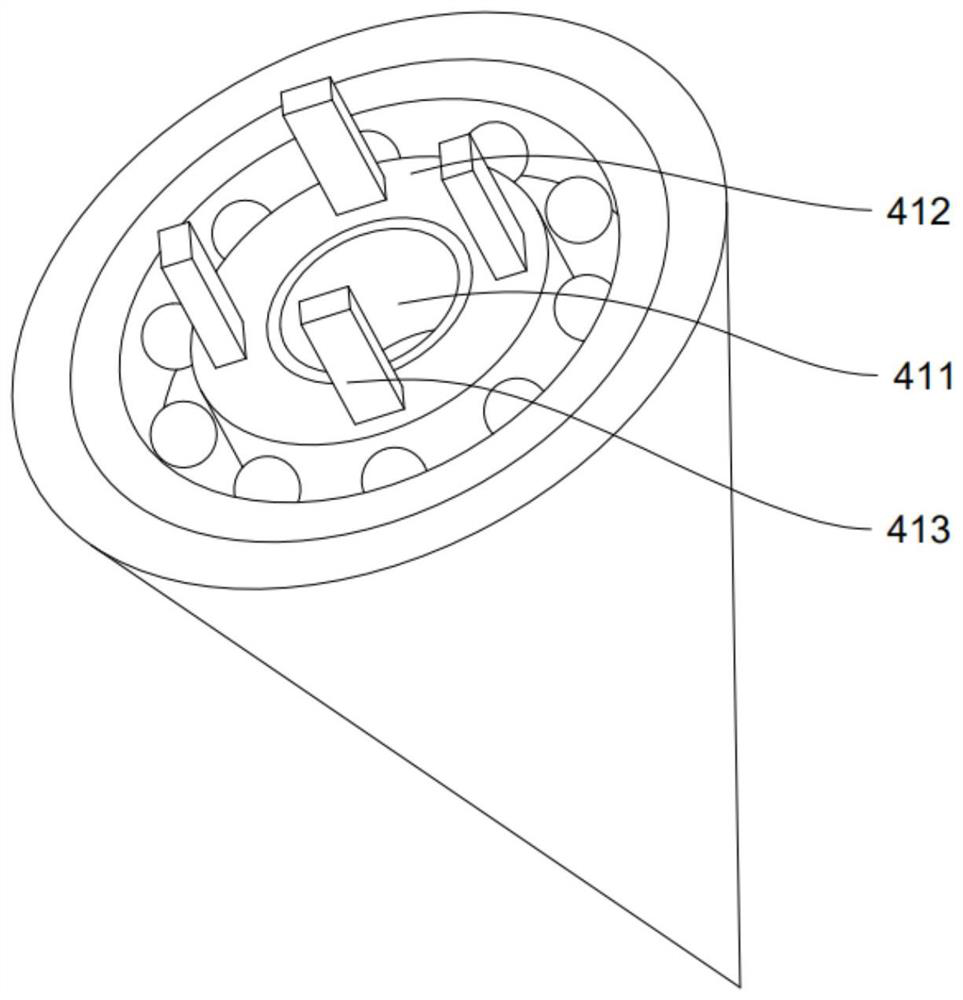

[0038] refer to Figure 2-5 , is the second embodiment of the present invention, which differs from the first embodiment in that: the branch pipe assembly 300 is provided with a vertebral body assembly 400, the vertebral body assembly 400 is provided with an upper vertebral body 410 and a lower vertebral body 420, and the upper vertebral body The body 410 is conical, the upper part is a tip, the diameter of the lower circular surface is larger than the pipe diameter of the branch pipe assembly 300, and the bottom is provided with a circular hole 411, and the inner surface of the circular hole 411 is provided with a thread groove, and the lower vertebral body 420 is arranged on the cylinder shaft 430. Below the upper vertebral body 410 .

[0039] Based on the above, the outer surface of the upper vertebral body 410 is smooth, and the tip is sharp, which can effectively break up the large pieces of dust that collapsed above, and the design of the smooth outer surface makes it di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com