Engine knock monitor and operation method thereof

A technology of engines and monitors, which is applied in the direction of engine components, machines/engines, collectors, etc., can solve problems such as assembly difficulties, input impedance mismatch, and high output impedance, so as to improve work efficiency, reduce auditory fatigue, and improve signal-to-noise than the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

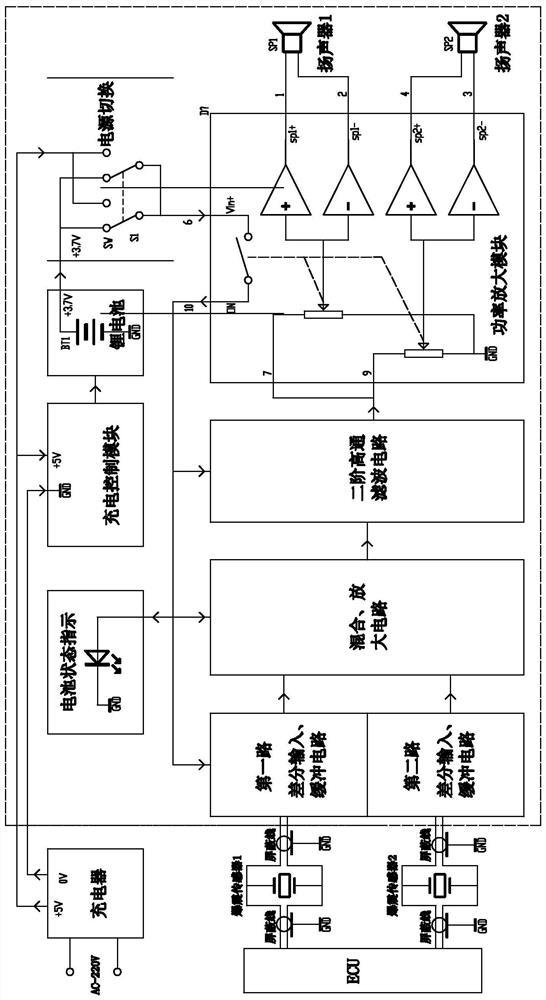

[0026] Specific implementation mode one: as figure 1 As shown, this embodiment discloses a kind of said engine knock listener, including listening module, first knock sensor, second knock sensor, four double-core shielded wires and ECU, said first knock sensor and the second knock sensor are both connected to the ECU and the monitoring module through two double-core shielded wires, wherein,

[0027] The first knock sensor and the second knock sensor are used to send a knock signal to the ECU and the listening module when the engine knocks;

[0028] The ECU is configured to process the knock signal;

[0029] The listening module is used for buffering and amplifying the knocking signal and separating an effective knocking signal for playing.

[0030] Further, the shielding layers of the four double-core shielding wires are all grounded to GND.

[0031] Specifically, the first knock sensor installed on the engine is connected to the ECU through a two-core shielded wire, and at...

specific Embodiment approach 2

[0036] Specific embodiment two: This embodiment discloses an operating method of an engine knock listener, and the operating method includes the following steps:

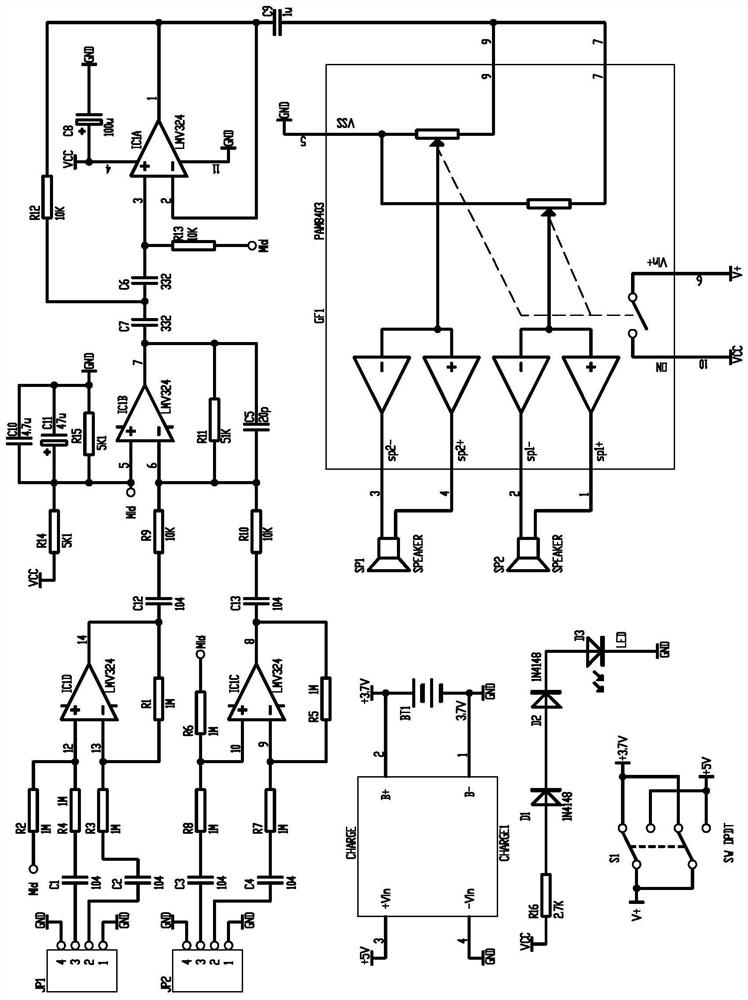

[0037]S1. The charger is connected to 220V AC. The 5V DC power output by the charger is used to charge the lithium battery BT1 through the charging control module in the monitoring module. The working power of the engine knock monitor is selected by the power switch to use the internal lithium battery. The battery is also an external charger; generally, the internal lithium battery can be used for short-term applications or for vehicle tests, and can be switched to an external charger for power supply when working for a long time or when the battery is out of power. It is more convenient to use only the internal lithium battery for power supply. It is beneficial to reduce noise and obtain a clearer monitoring effect;

[0038] S2. The power switch of the power amplifier module inside the monitor module is linked with...

specific Embodiment approach 3

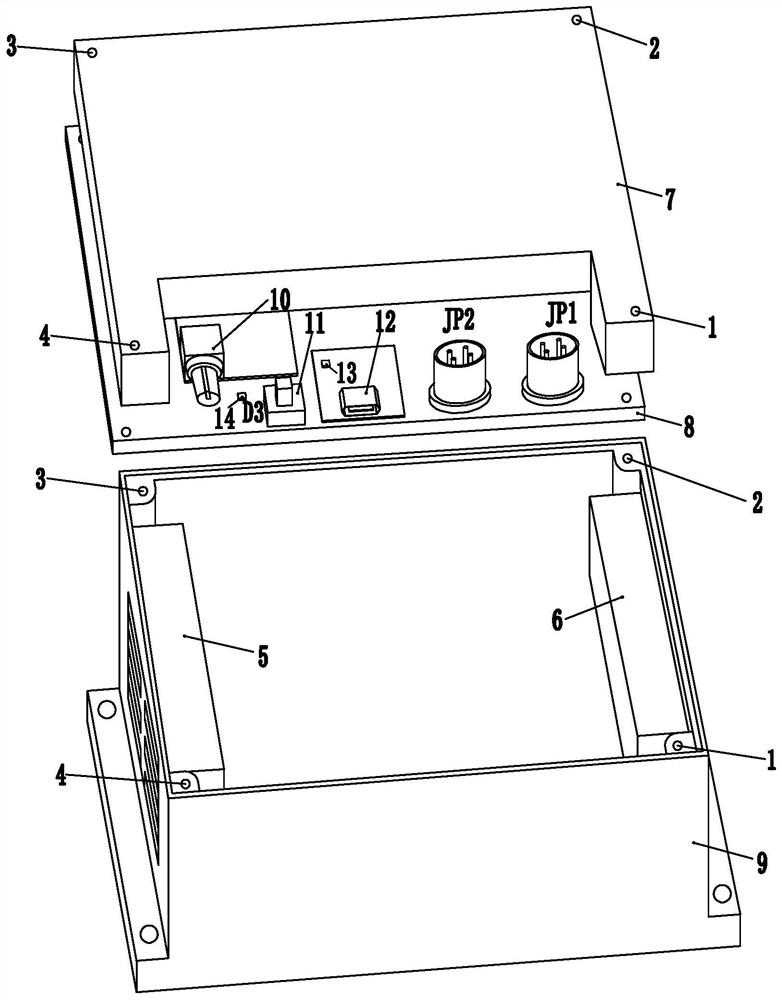

[0041] Specific embodiment three: this embodiment is a further description of the structure of a kind of engine knock listener in specific embodiment one, the structure of the engine knock listener is as follows figure 2 shown.

[0042] The structure of the engine knock listener includes an upper casing 7, a circuit board 8 and a lower casing 9. The three parts are connected by four M3 screws through holes one 1, hole two 2, holes three 3 and holes four 4. Fixed together, two small speaker cabinets (comprising speaker audio one 5 and speaker audio two 6) are fixed on the left and right sides of the lower housing 9, the two small speaker cabinets are connected with the circuit board 8 through wire harnesses, and the sound passes through the The opening grid is placed outside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com