Cast welding process for ultra-large busbar of nuclear 1E-grade lead-acid storage battery

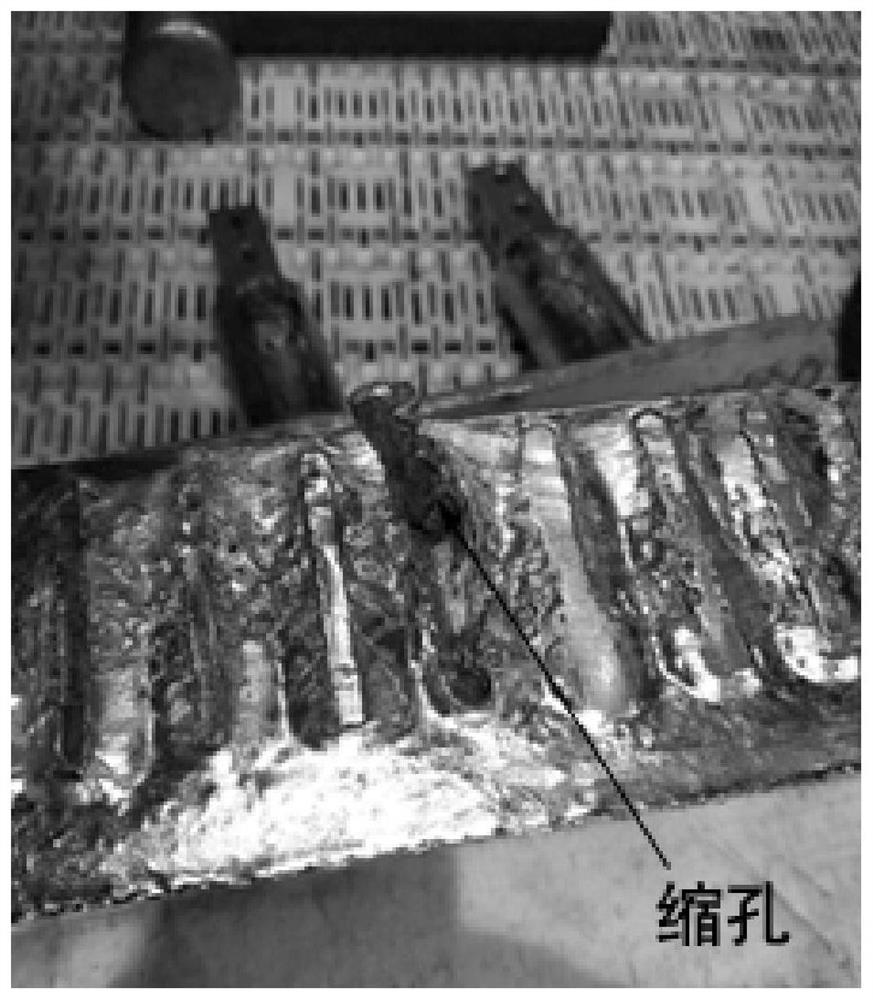

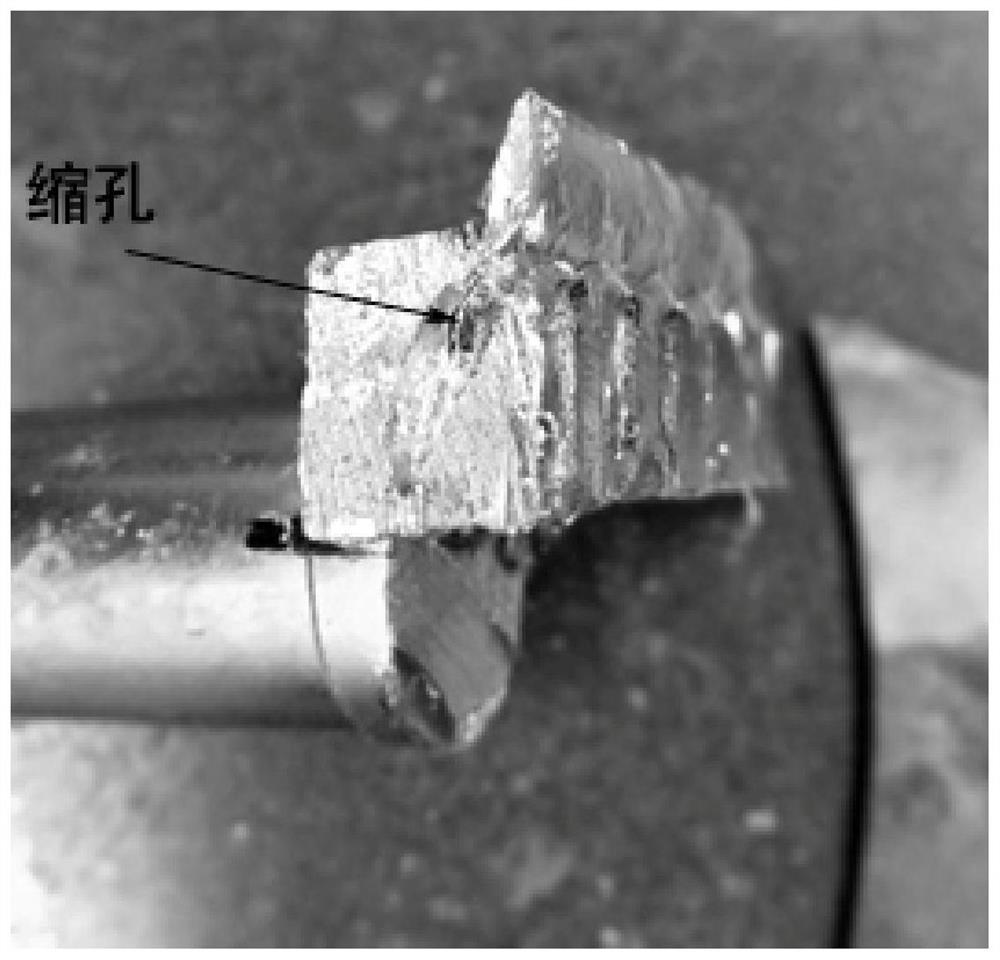

A lead-acid battery and busbar technology, applied in hot-dip plating process, metal material coating process, sustainable manufacturing/processing, etc., can solve problems such as shrinkage cavities, changes in timing lead supply, cold welding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0070] The casting and welding process of super-large busbars of nuclear 1E-class lead-acid batteries includes the tin dipping process for the negative tab and the casting and welding process for the negative tab.

[0071] The mass percent content of tin in the lead-tin alloy used for tin dipping is 60%, and the temperature of the tin pot is 230°C.

[0072] The tin dipping process for the negative tab includes the following steps:

[0073] Negative electrode ear cleaning: Use a wire brush to remove the attachments on the surface of the negative electrode ear to be treated, including lead plaster, etc.;

[0074] Dip in flux: The flux is divided into 2 brushes. The first roller brush brushes the flux to the surface of the negative electrode ear, and the second roller brush removes the excess flux on the surface of the negative electrode ear.

[0075] Tin dipping: Insert the negative electrode ear into the tin pot for 18 seconds, lift it up after the time is up, and the tin dipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com