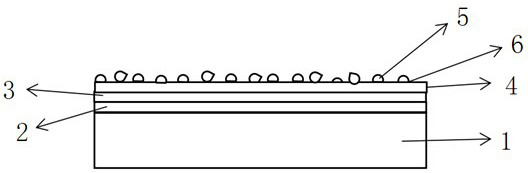

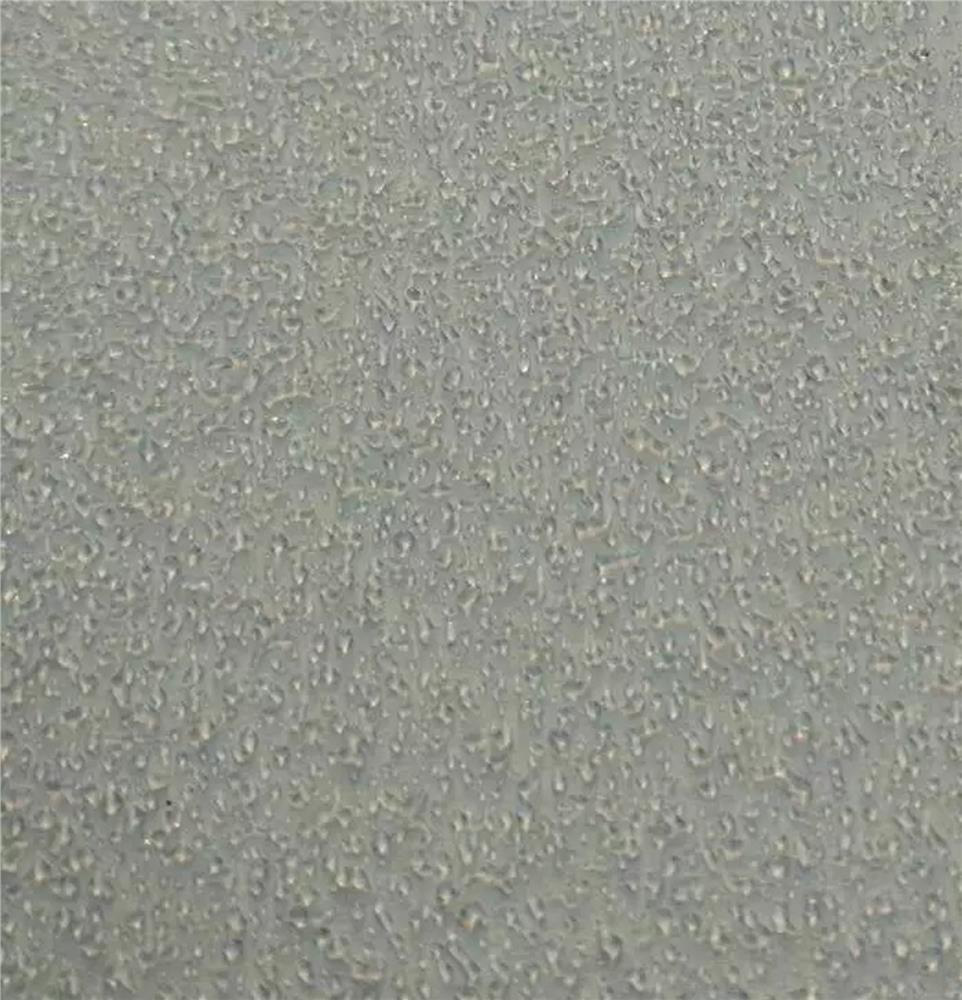

Dried dewdrops, dewdrop effect glaze ink and preparation method, slate and preparation method

A technology of dewdrops and dry granules, which is applied in the field of ceramic rock slabs, can solve problems such as uncontrollable unevenness, serious homogeneity, and aesthetic fatigue of users, so as to increase the firing range, have a good surface unevenness, and reduce the firing temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The dewdrop dry granules, applied on the surface of the slate, include the following components by weight:

[0041] 35~40 parts of nepheline syenite, 8-12 parts of burnt talc, 8-15 parts of calcite, 15-20 parts of zircon, 10-15 parts of quartz, 0-6 parts of barium carbonate, 2-5 parts of calcined alumina , 4-8 parts of air knife soil and 1-5 parts of zinc oxide;

[0042] The chemical composition percentages of dewdrop dry granules are as follows:

[0043] ZrO 2 :3-5%, SiO 2 :55-64%, Al 2 o 3 :8-12%, CaO:10-15%, MgO:3-6%, ZnO:1-5%, BaO:0-6%, K 2 O:3-4%, Na 2 O:3-5%, Fe 2 o 3 : 0-0.1%, B 2 o 3 : 2-5%, loss on ignition 3-5%.

[0044] Nepheline syenite is a solid solution of feldspar and nepheline. The zircon is a silicate mineral, and zircon is widely found in acidic igneous rocks and also in metamorphic rocks and other sediments. Zircon is chemically stable, so gem-quality zircon can also be seen in river gravel. There are many kinds of zircons, and differen...

Embodiment 2

[0052] The difference with embodiment 1 is that the dewdrop dry granules are selected as follows:

[0053] 35-38 parts of nepheline syenite, 10-12 parts of burnt talc, 8-10 parts of calcite, 15-17 parts of zircon, 10-12 parts of quartz, 1-2 parts of barium carbonate, 2-3 parts of calcined alumina , 4-5 parts of air knife soil and 1-3 parts of zinc oxide;

[0054] The chemical composition percentages of dewdrop dry granules are as follows:

[0055] ZrO 2 :4-5%, SiO 2 :58-62%, Al 2 o 3 :8-10%, CaO:10-12%, MgO:3-4%, ZnO:3-5%, BaO:2-3%, K 2 O:3-4%, Na 2 O:3-5%, Fe 2 o 3 : 0-0.1%, B 2 o 3 : 2-5%, loss on ignition 3-5%.

[0056] The dewdrop dry crystals in this example belong to the tetragonal crystal system, the crystals are square short columnar, square biconical, high hardness, diamond luster, high refractive index, strong gloss, high birefringence, high density, high dispersion and typical spectral features, etc.

[0057] Tested by a gloss meter model WGG60-E4, the ...

Embodiment 3

[0059] A dewdrop effect glaze ink,

[0060] Dewdrop effect glaze ink, including the following raw materials by weight:

[0061] Dewdrop dry granule glaze powder 35-55 parts, functional resin 4-8 parts, dispersant 25-45 parts, surfactant 2-4 parts, defoamer 0.2-0.5 parts, suspending agent 0.05-0.12 parts;

[0062] The dewdrop dry glaze powder comprises the following components by weight:

[0063] 35-38 parts of nepheline syenite, 10-12 parts of burnt talc, 8-10 parts of calcite, 15-17 parts of zircon, 10-12 parts of quartz, 1-2 parts of barium carbonate, 2-3 parts of calcined alumina , 4-5 parts of air knife soil and 1-3 parts of zinc oxide.

[0064] The functional resin is a mixture of carboxymethyl cellulose and acrylic resin, and the mass mixing ratio of carboxymethyl cellulose and acrylic resin is 1:1-5.

[0065] The dispersant is polymer polyacrylate emulsion.

[0066] The antifoaming agent is at least one of mineral oil and organic silicon; the suspending agent is cas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com