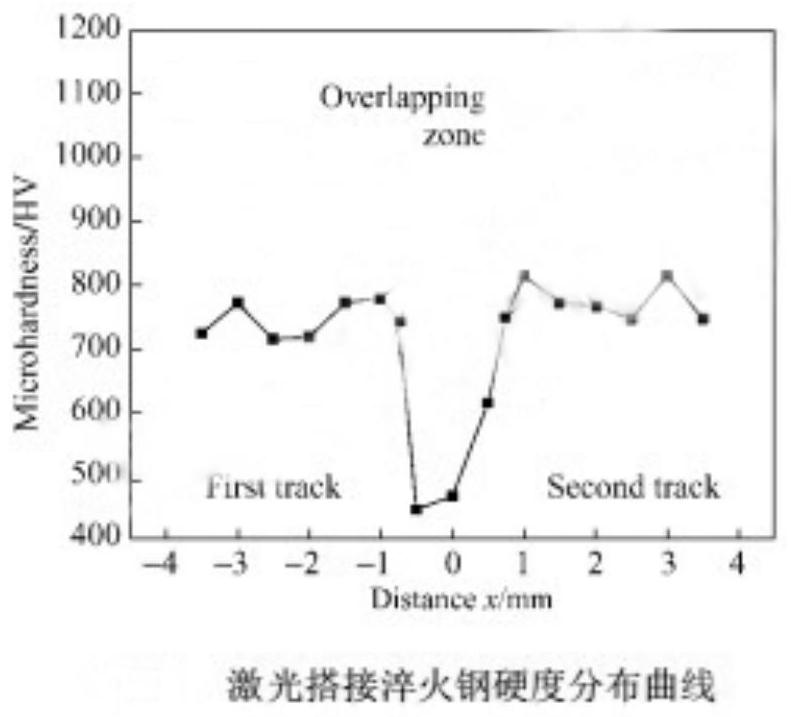

Laser quenching process for reducing width of laser quenching lap joint soft belt

A technology of laser quenching and soft belt, which is applied in the field of laser heat treatment, can solve the problems of uneven quenching hardening layer, etc., and achieve the effect of increasing the depth of quenching layer, increasing the entrance light spot, and shortening the collimation length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A laser quenching process for reducing the width of laser quenched lapped soft bands, comprising the steps of:

[0027] A. Clean the surface of the roll to be quenched to ensure that its surface meets the requirements of laser quenching;

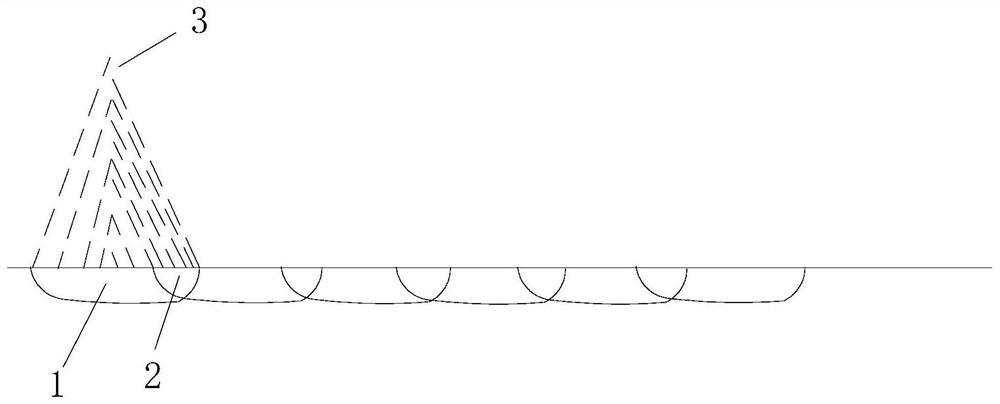

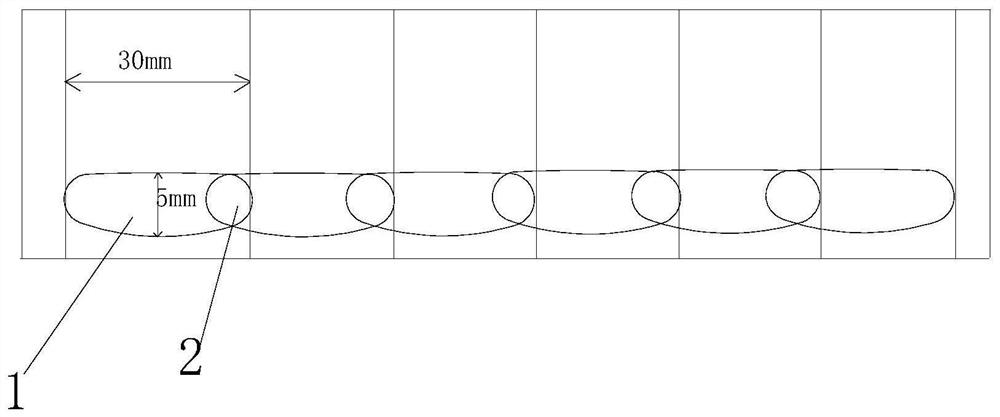

[0028] B. Select the laser line laser with multi-mode 1020um wavelength and 1000um fiber core diameter as the laser equipment, and adjust it, adjust the collimation degree from 100mm to 75mm, adjust the integrating mirror to 30*5mm, and adjust the process parameters. The moving speed is 180mm / min, the power is 3.5kw, and the emission direction of the laser beam is adjusted so that the energy of the spot is shifted to the overlapping overlapping end by 10°, and the overlapping rate is set to 10%, so as to realize the concentration of energy at the right end and reduce the virtual spot .

[0029] C. Use the adjusted laserline laser to perform multi-channel laser scanning quenching on the surface of the roll to be quenched;

[0030] D....

Embodiment 2

[0033] A laser quenching process for reducing the width of laser quenched lapped soft bands, comprising the steps of:

[0034] A. Clean the surface of the roll to be quenched to ensure that its surface meets the requirements of laser quenching;

[0035] B. Select the laser line laser with multi-mode 1020um wavelength and 1000um fiber core diameter as the laser equipment, and adjust it, adjust the collimation degree from 100mm to 75mm, adjust the integrating mirror to 30*5mm, and adjust the process parameters. The moving speed is 170mm / min, the power is 3.4kw, adjust the emission direction of the laser beam, so that the energy of the spot is shifted to the overlapping overlapping end by 8°, and the overlapping rate is set to 12%, so as to realize the concentration of energy at the right end and reduce the virtual spot .

[0036] C. Use the adjusted laserline laser to perform multi-channel laser scanning quenching on the surface of the roll to be quenched;

[0037] D. Measure ...

Embodiment 3

[0039] A laser quenching process for reducing the width of laser quenched lapped soft bands, comprising the steps of:

[0040] A. Clean the surface of the roll to be quenched to ensure that its surface meets the requirements of laser quenching;

[0041] B. Select the laser line laser with multi-mode 1020um wavelength and 1000um fiber core diameter as the laser equipment, and adjust it, adjust the collimation degree from 100mm to 75mm, adjust the integrating mirror to 30*5mm, and adjust the process parameters. The moving speed is 160mm / min, the power is 3.3kw, adjust the emission direction of the laser beam, so that the energy of the spot is offset by 10° to the overlapping overlapping end, and the overlapping rate is set to 10%, so as to realize the concentration of energy at the right end and reduce the virtual spot .

[0042] C. Use the adjusted laserline laser to perform multi-channel laser scanning quenching on the surface of the roll to be quenched;

[0043] D. Measure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com