Pretreatment method and extraction method of di(2-ethylhexyl) phosphate extraction agent

An ethylhexyl, pretreatment technology, applied in the field of extraction agent, acid extraction agent diphosphate, can solve the problems of increasing acid consumption, high-salt wastewater and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Pretreatment of extractant P204 by acetic acid buffer solution:

[0036] Using sulfonated kerosene as a diluent, the extractant P204 is prepared into an organic phase with a concentration of 0.25mol / L;

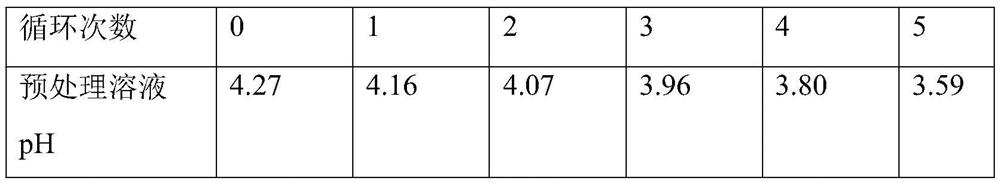

[0037] The HAc-NaAc aqueous solution with a total concentration of 3mol / L and a pH of 4.27 was mixed with the above-mentioned extractant in an organic equal volume ratio for 15 minutes, then left to separate phases, and the resulting organic phase was taken as the pretreated extractant, and the remaining aqueous phase was Circulation is used for the pretreatment of P204, and the water phase that obtains after multiple circulation pretreatment, i.e. the pH value of pretreatment liquid is tested, and its result is as shown in table 1:

[0038] Table 1 The impact of the cycle times on the pH value of the pretreatment solution

[0039]

[0040] It can be seen that the pretreatment solution has a higher buffer capacity, and the H released by P204 + Has a good cushioning...

Embodiment 2

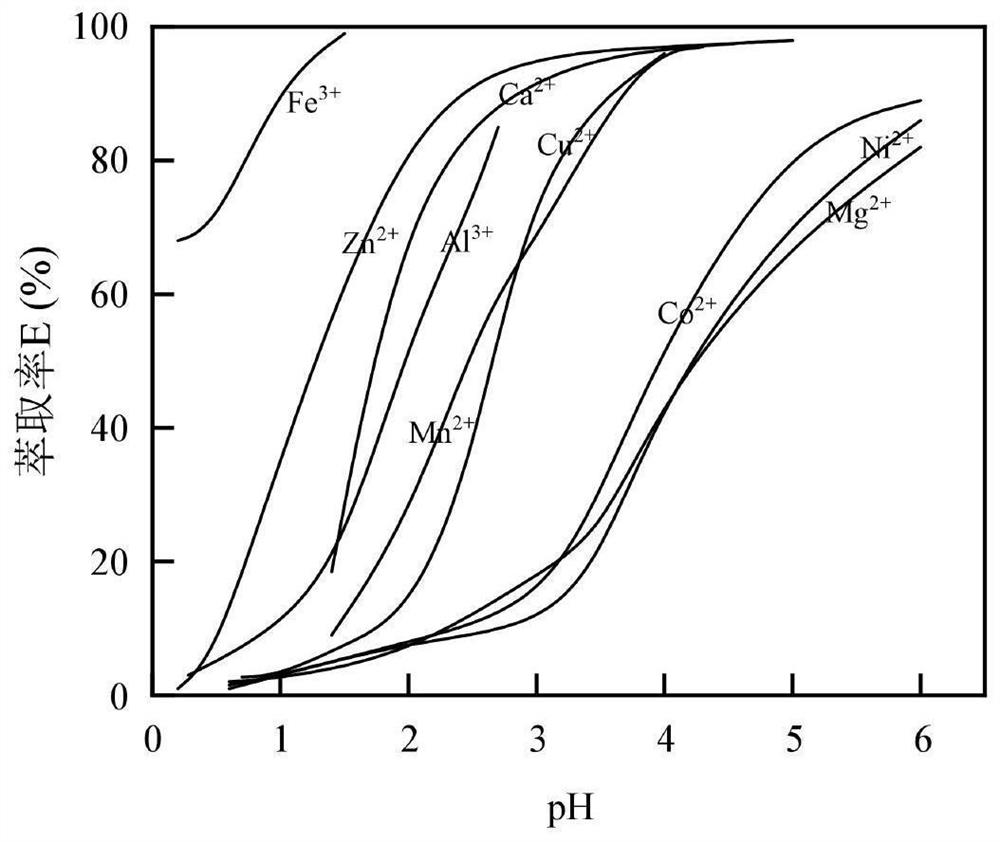

[0042] The extractant after the pretreatment obtained in Example 1 extracts and separates cobalt and manganese mixed feed liquid, wherein the feed liquid contains 2g / L Co 2+ and 2g / L Mn 2+ The dilute sulfuric acid aqueous solution, the extraction conditions are: temperature 25 ℃, ratio O / A is 1: 1, extraction equilibrium time is 15min, manganese, cobalt extraction and separation results are shown in Table 2:

[0043] Table 2 Manganese, cobalt extraction and separation results

[0044]

[0045] It can be seen that the pH value of the raffinate obtained from the feed liquid with an initial pH value in the range of 3.60-4.60 is similar, and the extraction effect is equivalent. Therefore, there is no need to strictly control the acidity of the feed liquid before extraction, and it is not necessary to add any acid or alkali to adjust the acidity during the extraction process. The primary extraction rate of the separated manganese is more than 90%, and the extraction efficiency...

Embodiment 3

[0047] The P204 of 0.25mol / L was processed by the same pretreatment method as in Example 1, and only the pH value of the pretreatment solution was changed to 3.64. The pretreated extractant extracts and separates the above-mentioned cobalt and manganese mixed feed liquid, the pH of the feed liquid=4.00, Co 2+ and Mn 2+ The concentration of all is 2g / L, and extraction condition is identical with embodiment 2. After extraction, the pH value of the raffinate was 3.16, the extraction rates of manganese and cobalt were 89.5% and 13.3% respectively, and the separation factor was 55.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com