Cold-rolled flat steel product for packaging

A product, flat steel technology, applied in the field of cold-rolled flat steel products, can solve the problems of expensive alloy elements and reduced cold-rollability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

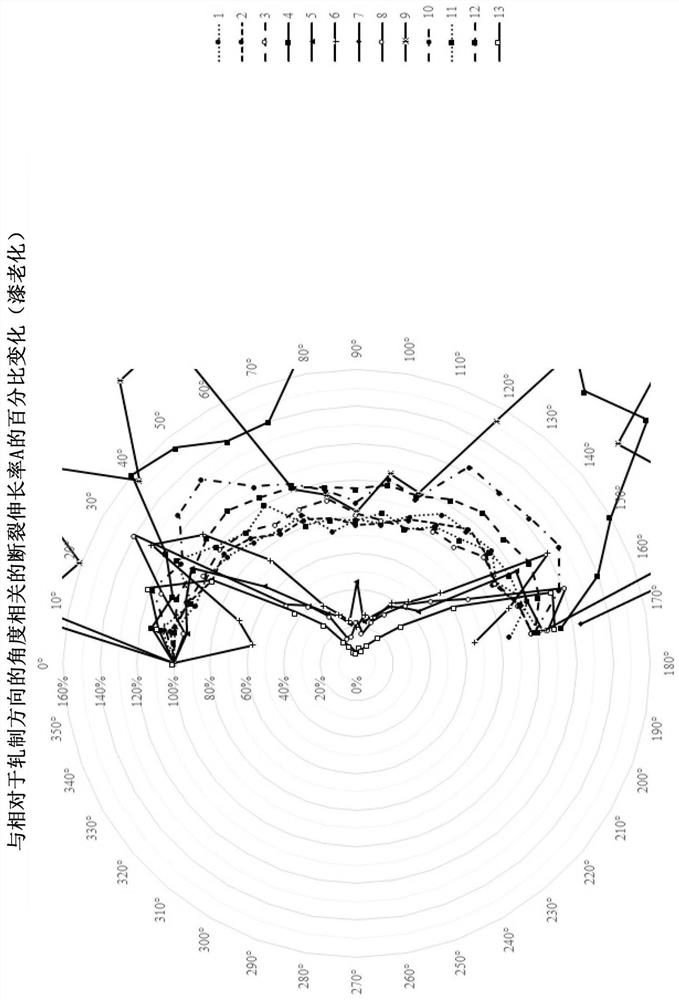

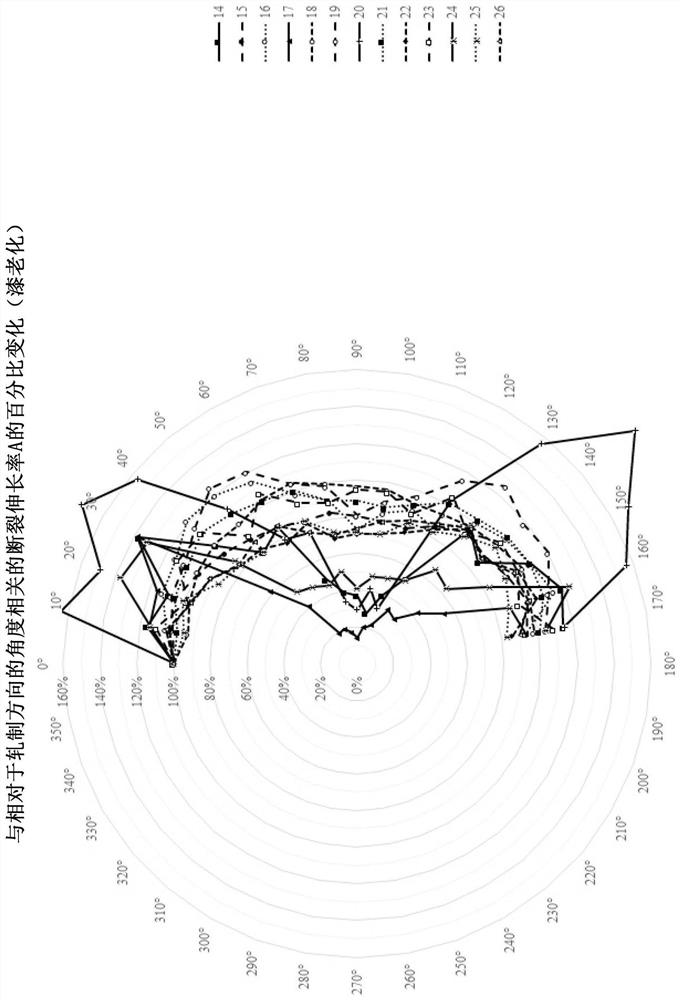

[0122] Embodiments of the present invention and Comparative Examples set forth below.

[0123] Molten steel alloying components by hot rolling and subsequent cold rolling recited in Table 1 having made flat products (steel sheets).

[0124] Then, by annealing the flat steel product in the duration of 45 seconds held device on the annealing temperature of 640 deg.] C, recrystallization of the cold-rolled flat products way is annealed in a continuous annealing furnace.

[0125] Thus heat treated steel sheet are listed in Table 1 in Table 2 Method and material parameters, wherein

[0126] -N (after nitriding) nitrogen content after nitriding annealing furnace,

[0127] -D is the plate thickness (in mm),

[0128] -NWG rolling, then the system (in%) during the second cold rolling,

[0129] -NH3 ammonia content (volume percent) of the annealing furnace,

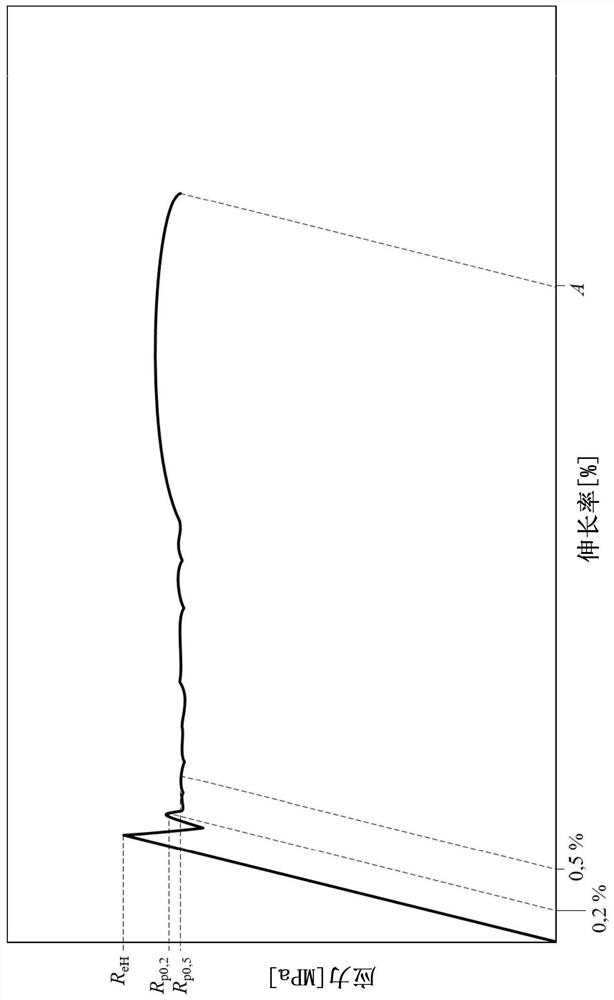

[0130] -Rp0.5 was 0.5% yield strength in the rolling direction (in MPa),

[0131] -A elongation at break in the rolling direction (in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chord length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com