Non-ironing textile

A technology for textiles and compounds, applied in the field of textiles, can solve problems such as time-consuming, unfavorable continuous production, and complex processing methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

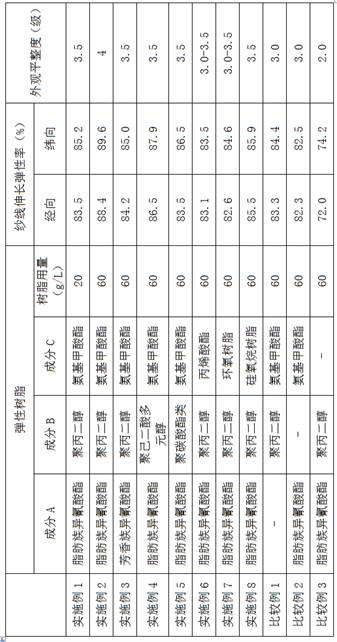

[0037] Choose from 45 S Plain woven gray fabric formed from polyester fiber spun yarn (gram weight 120g / m 2 , warp and weft density 133 pieces / inch*72 pieces / inch) as the product to be processed, put the product to be processed into the resin finishing liquid on the rolling car, and perform padding under the conditions of roll pressure 0.3Mpa and speed 2.50m / min Processing, followed by drying at 130°C for 2 minutes, and finally setting at 170°C for 1 minute, wherein the resin finishing solution contains dicyclohexylmethane-4,4'-diisocyanate, polypropylene glycol and carbamic acid Elastic resin composed of ester compounds, the amount of elastic resin is 20g / L, to obtain the non-ironing textile of the present invention. The specific parameters are shown in Table 1.

Embodiment 2

[0039] The consumption of elastic resin is 60g / L, all the other are the same as Example 1, obtain the non-ironing textile of the present invention. The specific parameters are shown in Table 1.

Embodiment 3

[0041] Dicyclohexylmethane-4,4'-diisocyanate in the resin finishing solution was replaced with toluene diisocyanate (TDI), and the rest was the same as in Example 2 to obtain the non-ironing textile of the present invention. The specific parameters are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com