Waterproof and drainage floor structure of machine room channel

A technology for waterproofing and drainage, computer room, applied in drainage structures, floors, building structures, etc., can solve the problems of not considering the waterproofing and drainage of aisles, safety problems, poor economy, etc., to achieve good economic benefits and reduce costs. , the effect of low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation of the present invention, only for example. At the same time, the advantages of the present invention will become clearer and easier to understand through the description.

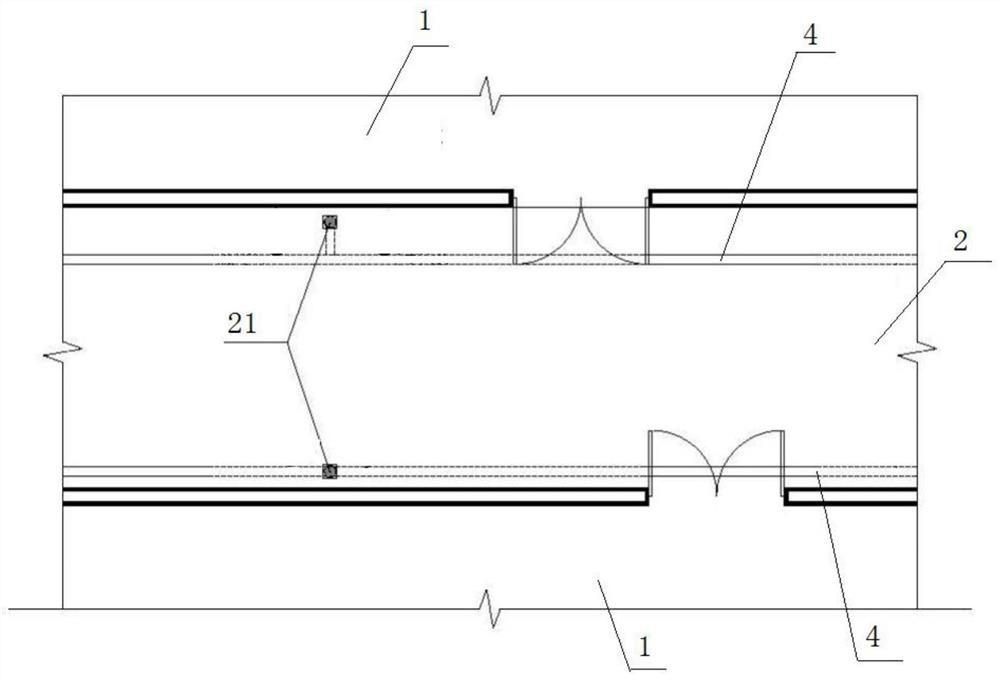

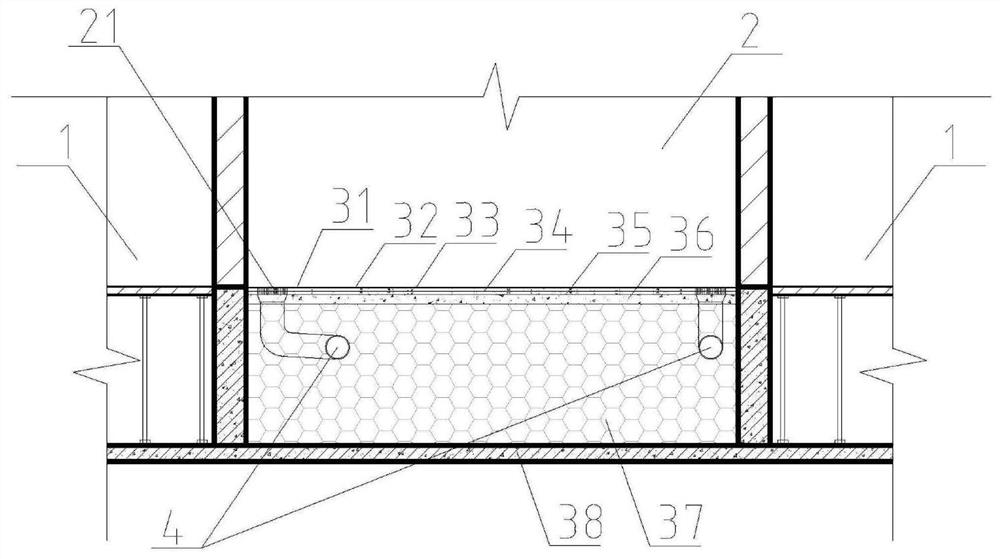

[0020] Referring to the accompanying drawings, it can be seen that the waterproof and drainage floor structure of the passageway of the machine room is characterized in that: it includes a walkway 2 between two machine rooms 1;

[0021] There are floor drains 21 on both sides of the walkway 2, and a solvent-free epoxy coating layer 31, a plain cement slurry bonding layer 32, a cement mortar protective layer 33, a polyurethane waterproof coating layer 34, and a cement mortar coating layer are sequentially arranged below the walkway 2 from top to bottom. Leveling layer 35, fine stone concrete cushion layer 36, foam concrete backfill layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com