Nitrogen foam induced flow experimental device for simulating coiled tubing and use method thereof

A technology of nitrogen foam and experimental equipment, which is applied in the direction of earthwork drilling, production fluid, measurement, etc., can solve the problems of inability to monitor pressure changes, inability to realize automatic addition of reactants, inability to simulate reservoir pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

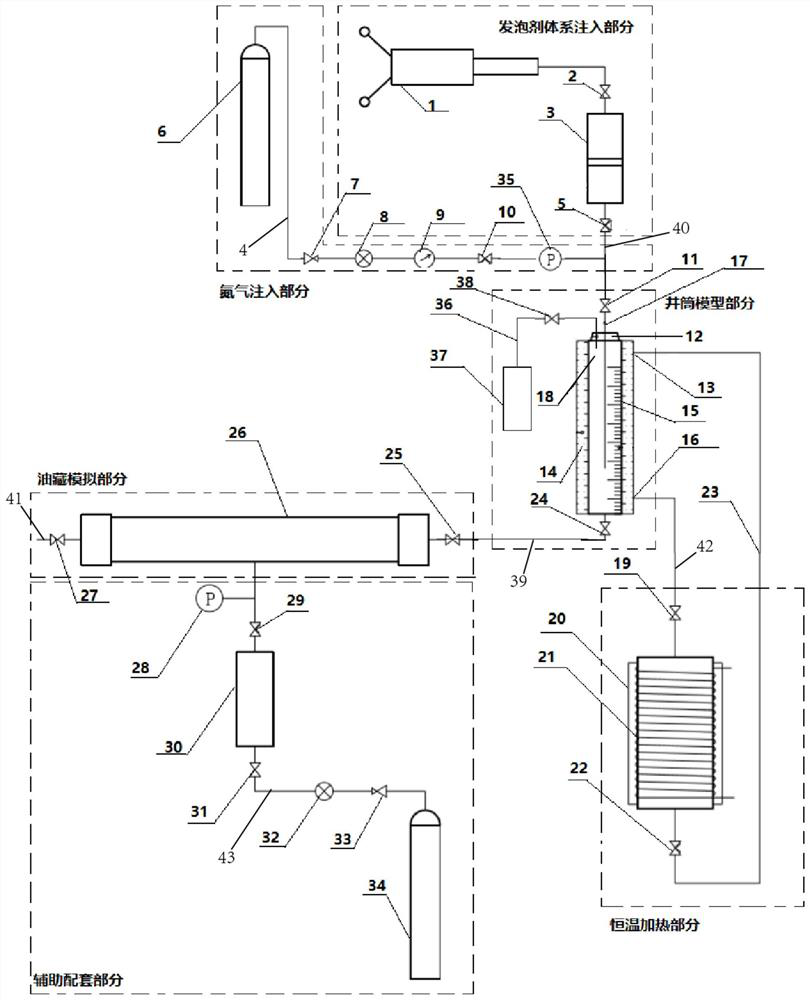

[0037] A nitrogen foam induced blowout experiment device for simulating coiled tubing, including a nitrogen injection part, a foaming agent system injection part, a wellbore model part, a constant temperature heating part, a reservoir simulation part and auxiliary supporting parts,

[0038] The nitrogen injection part comprises a nitrogen cylinder 6, a pressure reducing valve 7, a pressure regulating valve 8 and a nitrogen valve 10. The outlet of the nitrogen cylinder 6 is connected to the foaming nitrogen mixing valve 11 through the first pipeline 4, and on the first pipeline 4 is Set the pressure reducing valve 7, the pressure regulating valve 8 and the nitrogen valve 10 sequentially from left to right;

[0039] The foaming agent system injection part includes a metering pump 1, a foaming inlet valve 2, a piston container 3 and a foaming outlet valve 5, the outlet of the metering pump 1 is connected to the inlet of the foaming inlet valve 2, and the outlet of the foaming inle...

Embodiment 2

[0044] On the basis of Embodiment 1, the constant temperature heating part includes a water bath inlet pipeline 42, a water bath drain pipeline 23, a water bath device 20 and a heating wire 21, and the heating wire 21 is wound outside the water bath device 20, and the first part of the water bath inlet pipeline 42 The end is connected to the constant temperature water inlet 16 arranged on the constant temperature water bath device 14, the tail end of the water bath inlet pipe 42 is connected to the top of the water bath device 20, and a heating outlet valve 19 is arranged on the water bath inlet pipe 42, and the water bath drainage pipe The head end of 23 links to each other with the constant temperature water outlet 13 that is arranged on the constant temperature water bath device 14, and the tail end of water bath drainage pipeline 23 links to each other with the bottom end of water bath device 20, is provided with heating inlet valve 22 on water bath drainage pipeline 13.

Embodiment 3

[0046] On the basis of the second embodiment, a flow meter 9 is also provided on the first pipeline 4 between the pressure regulating valve 8 and the nitrogen valve 10 .

[0047] A second pressure gauge 35 is also provided on the first pipeline 4 between the nitrogen valve 10 and the foaming nitrogen mixing valve 11 .

[0048] The high-pressure visible wellbore 18 adopts the structure of pressure-resistant and temperature-resistant tempered glass. The pressure-resistant pressure of the high-pressure visible wellbore 18 is 4-5MPa, and the temperature-resistant temperature of the high-pressure visible wellbore 18 is 160-180°C. A scale scale 15 is provided on the side wall of the casing, which is used to adjust the insertion height of the coiled tubing 17 in real time, so as to realize the research on the influence of the position of the coiled tubing 17 on the process effect.

[0049] A first pressure gauge 28 is also provided on the pressure simulation pipeline 73 between the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com