Semitrailer suspension system test method and terminal

A technology of suspension system and testing method, which is applied in the direction of vehicle suspension/shock absorbing mechanism testing, etc., and can solve problems such as unreasonable distance between roadblocks, time-consuming and labor-intensive, and inapplicability of roadblocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

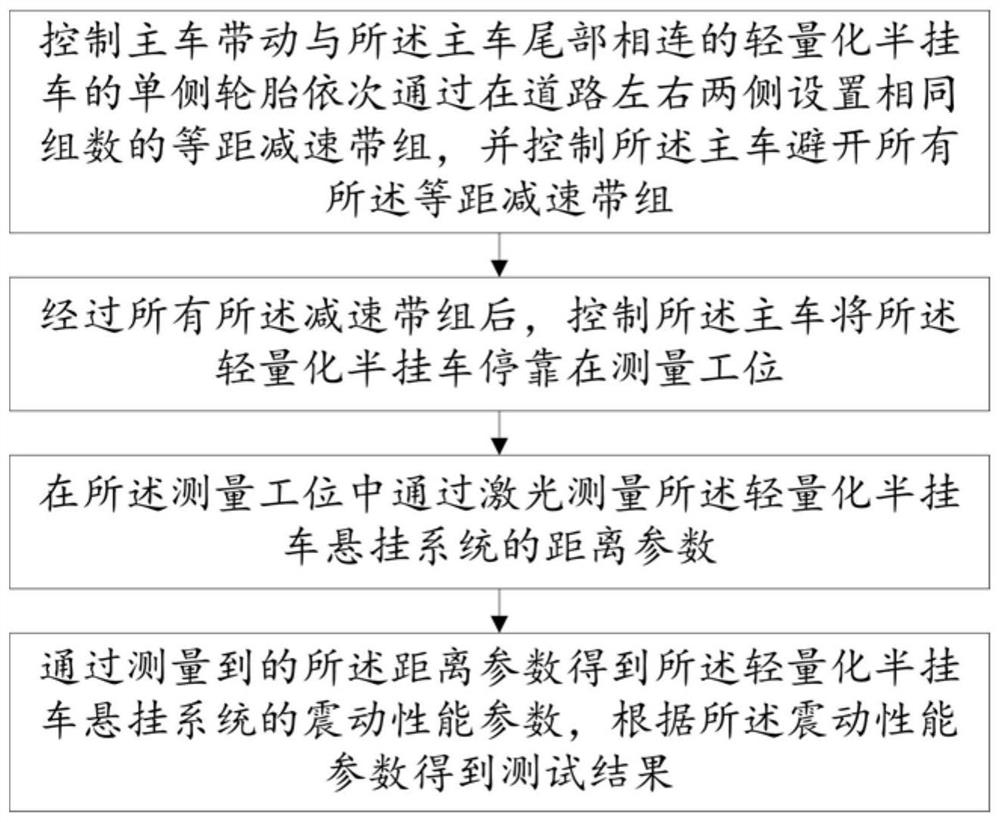

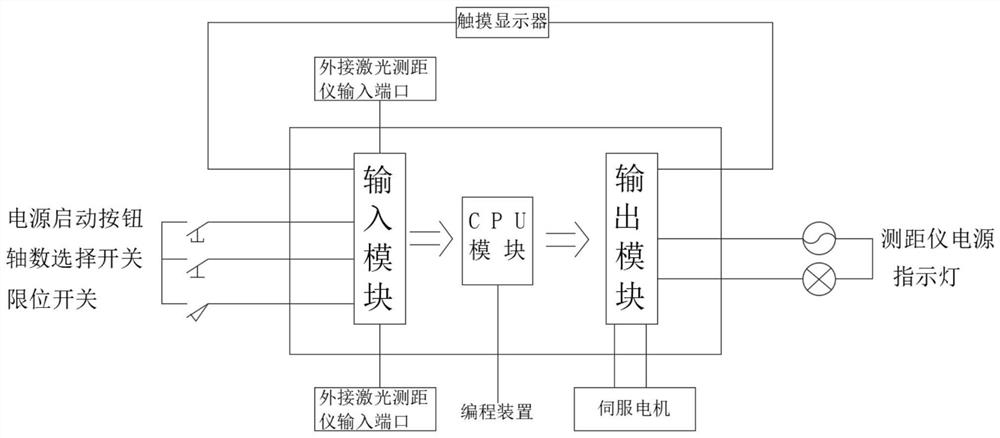

[0071] Please refer to figure 1 , image 3 and Figure 4 , a test method for a suspension system of a semi-trailer, comprising the steps of:

[0072] S1. Control the main vehicle to drive the unilateral tires of the lightweight semi-trailer connected to the rear of the main vehicle to pass through the same number of equidistant deceleration belt groups on the left and right sides of the road in turn, and control the main vehicle to avoid all The above isometric speed bump group.

[0073] Specifically, the main vehicle is the front of a semi-trailer, with a short body and an engine cab, connected to the lightweight semi-trailer through a traction pin; the lightweight semi-trailer has a long body, and its main profiles are high-strength aluminum alloys.

[0074] In this embodiment, the high-strength aluminum alloy profile lightweight semi-trailer is placed on the road with the same number of equidistant deceleration belt groups on the left and right sides of the road. The sp...

Embodiment 2

[0096] Please refer to Figure 5 Compared with Comparative Example 1, this embodiment further defines how to set up equidistant deceleration belt groups. Specifically, setting the same number of equidistant deceleration belt groups on the left and right sides of the road includes:

[0097] Set a set of deceleration belt groups alternately on the left and right sides of the road every first preset distance until the preset number of deceleration belt groups is set. The deceleration belt group includes a preset number of deceleration belts. Every second A speed bump is set at a preset distance;

[0098] The value range of the first preset distance is [l, 2l], l represents the body length of the semi-trailer, the value range of the second preset distance is [s, 2s], s represents the length of the semi-trailer Trailer wheel diameter.

[0099] In this embodiment, the equidistant speed bump road surface contains 10 sets of speed bumps, and each set of speed bumps contains two spee...

Embodiment 3

[0108] Please refer to figure 2 , a test terminal for a suspension system of a semi-trailer, comprising a memory, a processor, and a computer program stored on the memory and operable on the processor, when the processor executes the computer program, the first embodiment or the implementation is realized Each step of the test method of the semi-trailer suspension system in Example 2.

[0109] In summary, the present invention provides a test method and terminal for a suspension system of a semi-trailer, which simulates bumpy roadblock tests by setting equidistant S-shaped speed bumps, laser range finders, and linear guide rails on the road surface. Since the body of the semi-trailer is long and the body of the main vehicle is short, the distance between the tires of the semi-trailer and the tires of the main vehicle is relatively long. Control the driving direction of the front of the main vehicle, give the lightweight semi-trailer body leaf spring bracket, suspension syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com