Integrated intelligent production platform for raw materials of canned peaches based on multi-axis robot

A multi-axis robot and intelligent production technology, applied in the direction of instruments, comprehensive factory control, program control, etc., to achieve high flexibility and high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

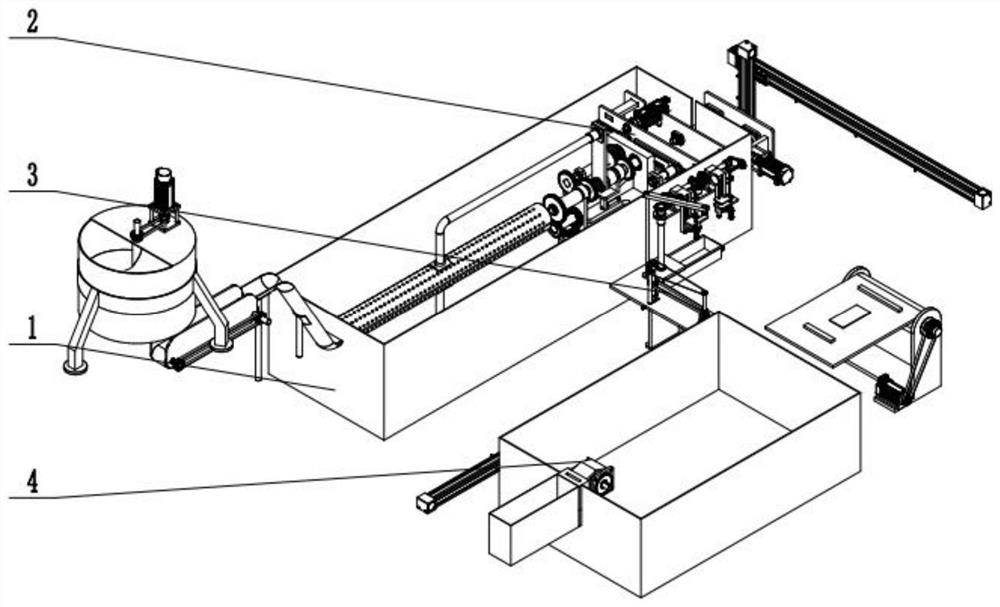

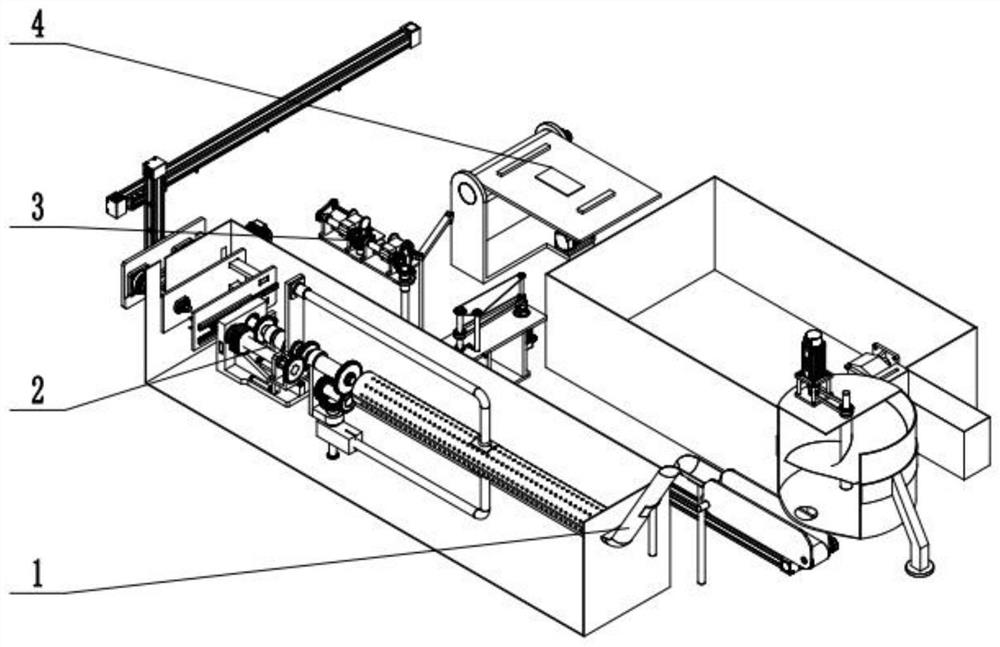

[0025] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9 In order to solve the above technical problems, an intelligent production platform for canned peach raw materials based on multi-axis robots, including a feeding tank device 1, a transfer active manipulator device 2, a cutting Four-axis manipulator device 3 for petal removal and peeling and unloading device 4, other devices are installed through the feeding tank device 1 to provide feeding, cleaning, soaking and other actions, and the main transfer action manipulator device 2 completes material transfer assistance and other related parts Action, flap cutting and pitting four-axis manipulator device 3 realizes material flap cutting, pitting, peach pit collection and other actions, peeling and unloading device 4 realizes the action of soaking and peeling, automatic feeding and automatic collection of epidermis, realizing high adaptability and high efficiency. The function of automatic processing of peach petals required by...

specific Embodiment approach 2

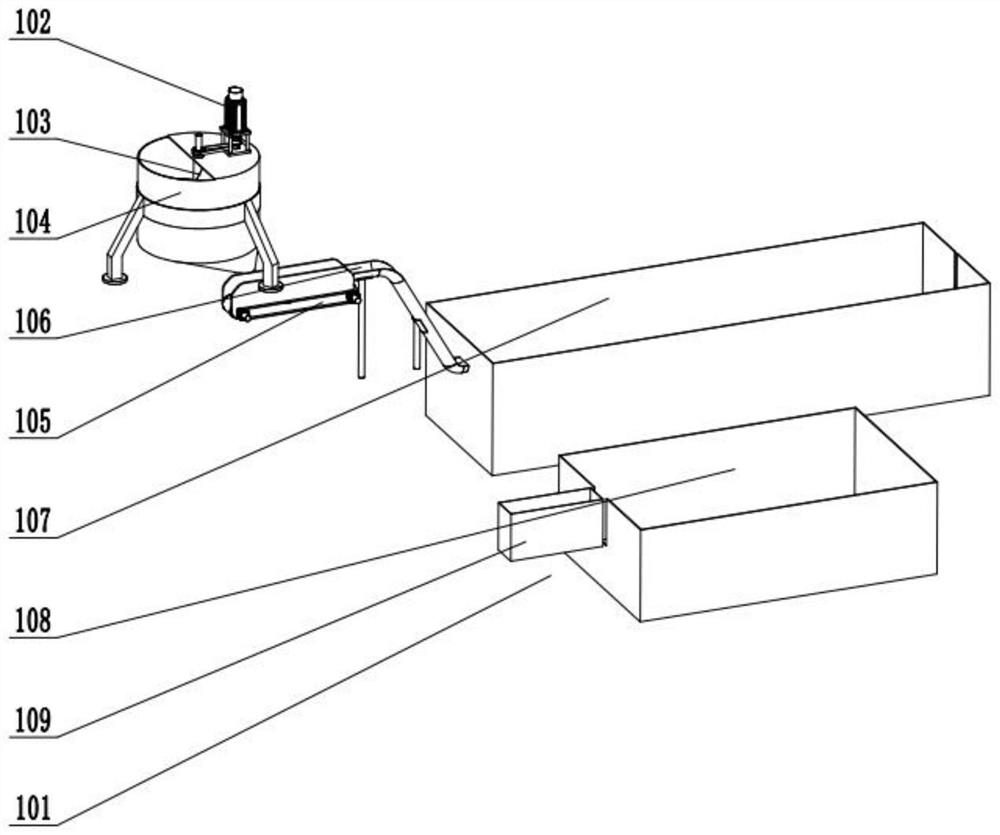

[0027] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, and 9 illustrate this embodiment, and this embodiment will further describe Embodiment 1. The described feeding water tank device 1 includes an installation main body 101, a fruit-feeding motor 102, a screw conveyor Axle 103, send fruit limit barrel 104, send fruit conveyer belt 105, slideway 106, cleaning pool 107, peel and soak pool 108, receive fruit box 109, at first the peach fruit to be processed is filled in the fruit limit barrel 104, Turn on the fruit delivery motor 102, the screw feed shaft 103 rotates intermittently, and the peaches are transported from the material delivery port below the fruit delivery limit barrel 104 to the fruit delivery conveyor belt 105, and the fruit delivery conveyor belt 105 transports the fruit along the slideway 106 to the next process.

specific Embodiment approach 3

[0029] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, and 9 illustrate this embodiment, and this embodiment will further describe Embodiment 1. The transfer active manipulator device 2 includes a biaxial robot 201, a transfer plate 202, a cleaning Overturning motor 203, motor connection drive shaft 204, active overturning bevel gear 205, driven overturning bevel gear 206, overturning main screw shaft 207, overturning platform plate 208, clamping motor 209, clamping main shaft 210, clamping transmission shaft 211 , Upper clamping rack 212, lower clamping rack 213, No. 1 clamping slide rail 214, No. 2 clamping slide rail 215, No. 1 clamping block 216, No. 2 clamping block 217, opening and closing driven shaft 218 , opening and closing driving shaft 219, opening and closing upper arm 220, opening and closing upper arm lever 221, upper cleaning cage 222, opening and closing driven shaft sleeve 223, long opening and closing control cylinder 224, control fork plate 225, opening and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap