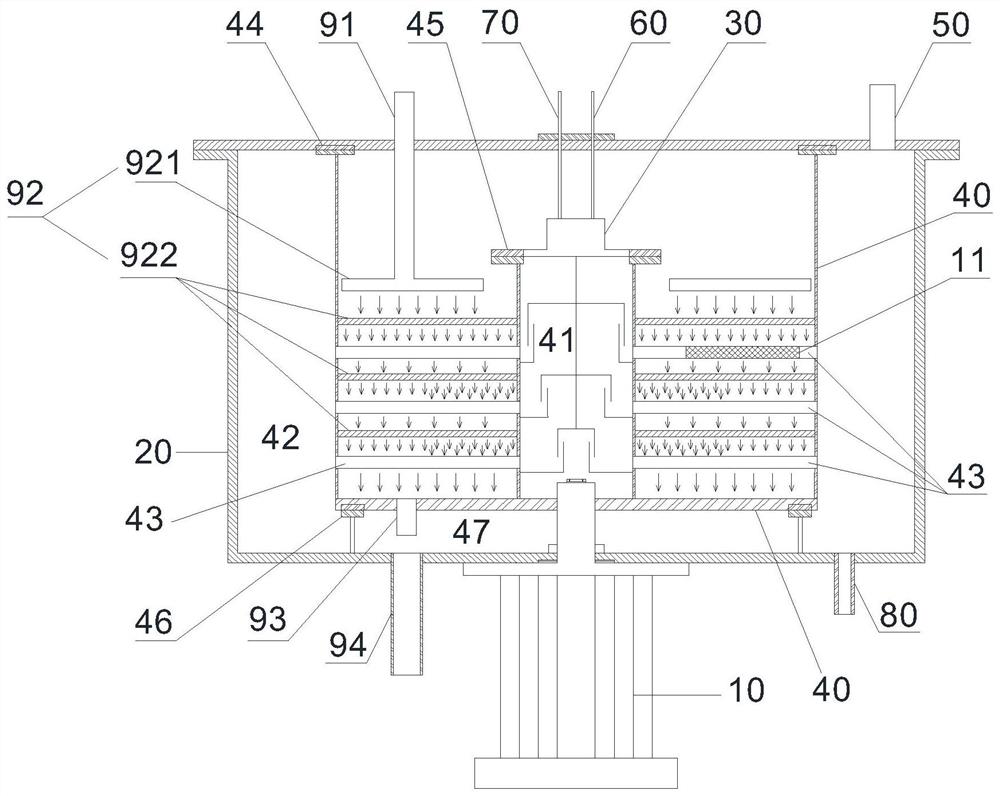

A kind of supergravity channel rotating bed for rapid heat exchange and application method thereof

A rotating bed and supergravity technology, applied in chemical instruments and methods, chemical/physical/physicochemical fixed reactors, climate sustainability, etc., can solve problems such as inability to exchange in time, and achieve contact avoidance and enhanced exchange Thermal, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100]The isooctanol nitration reaction is carried out by adopting the supergravity channel rotating bed of the present invention. The experimental conditions are as follows: the rotating bed speed of the supergravity channel is 200-2000r / min, the number of stainless steel channels is two layers, the number of fixed straight circular channels in each layer is 20, the channel diameter is 5mm, and the temperature of the heat exchange medium water is maintained at 10 ℃ ; 10 mesh hydrophobic wire mesh is fixed on the heat exchange medium redistribution plate, the volume ratio of nitric acid and sulfuric acid is 1:1, the volume flow rate of nitric-sulfur mixed acid is 40L / h, and the volume flow rate of isooctanol is 30L / h. The two liquids are respectively transported to the two inlets of the rotating bed reactor through a constant flow pump that can precisely control the flow. The liquid product flows out from the outlet at the bottom of the outer cavity of the rotating bed into th...

Embodiment 2

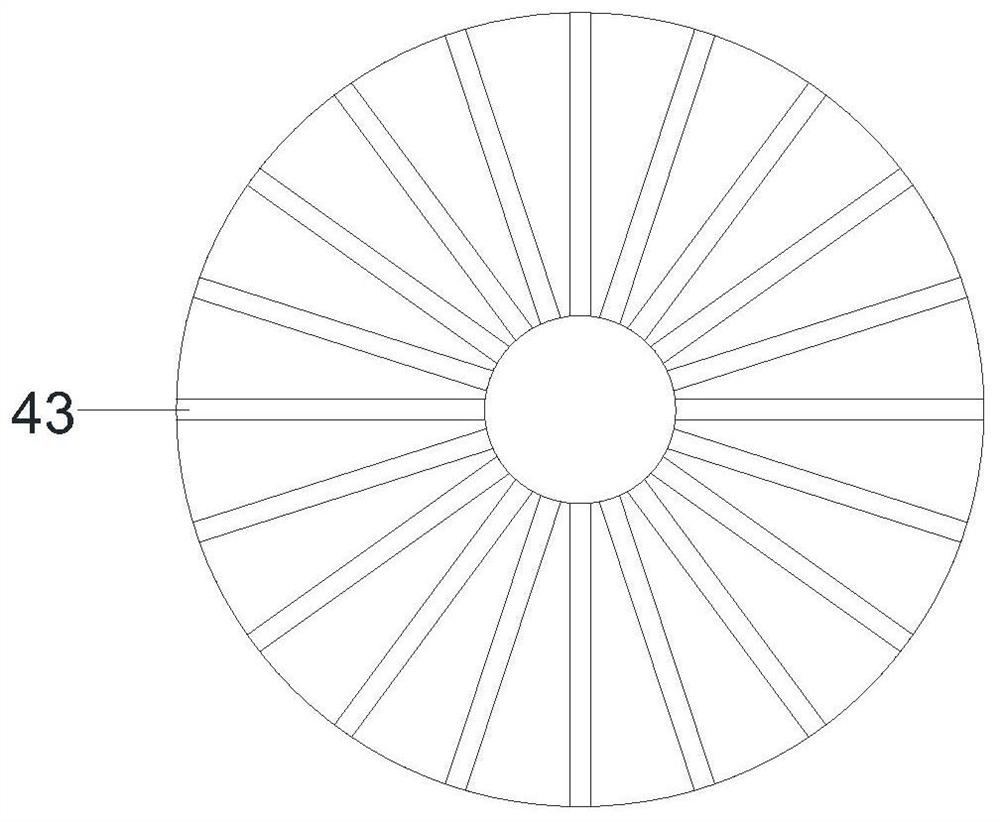

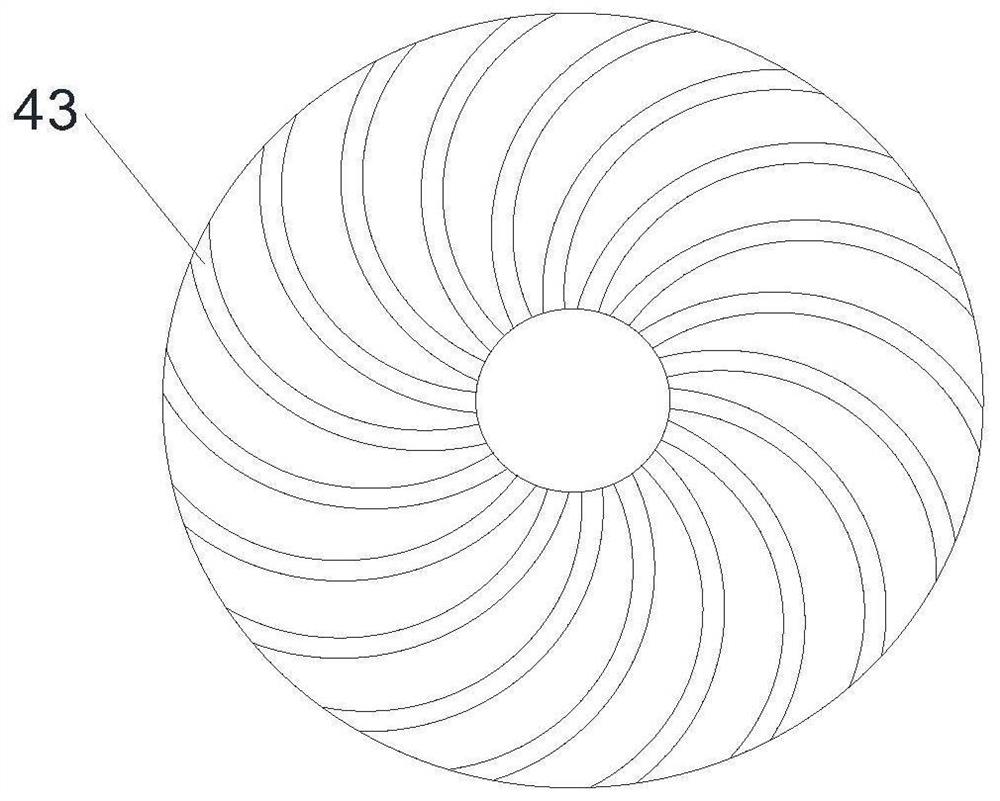

[0102] Adjust the device in Example 1, and adjust the straight circular rotating channel structure to be an arc or broken line type, such as image 3 or Figure 4 As shown in the figure, the contact time of the material in the channel can be prolonged, and it is found that the purity and yield of the product isooctyl nitrate are improved to varying degrees, and the effect is fold line > arc shape. At a rotational speed of 1600 r / min, the zigzag channel structure makes the purity and yield of the product isooctyl nitrate 92% and 90%, respectively.

Embodiment 3

[0104] On the basis of Example 1, the heat exchange medium redistribution plate is changed to an annular plate, which is divided into 3 regions from the inside to the outside, and the opening area of each region is 80%, 60% and 40% respectively, and the annular plate is from the inside to the outside. The inclination angle is 45°, which strengthens the redistribution of the heat exchange medium on the channel surface. Under the rotating speed of 1200r / min, the purity and yield of the product isooctyl nitrate were 94% and 93%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com