Preparation method of 0D/3D Fe2O3 QDs/g-C3N4 hybrid photo-Fenton catalyst

A g-c3n4, catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as increasing the difficulty of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

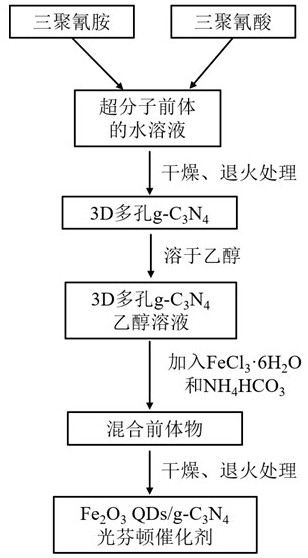

[0024] First, dissolve 2.0g melamine and 2.0g cyanuric acid in 100mL ultrapure water and stir for 12h; then transfer the above solution to a glass dish and dry at 60°C for 12h; After annealing for 4 hours, a yellowish 3D porous g-C 3 N 4 sample. Take 0.9g of the above 3D porous g-C 3 N 4 Disperse the sample in 100mL ethanol, stir magnetically for 2h to achieve uniform dispersion to obtain g-C 3 N 4 Ethanol dispersion, add 0.27g FeCl to the above dispersion 3 ·6H 2 O and 0.24gNH 4 HCO 3 And stirred for 12h, the product was centrifuged, washed, and dried overnight at 60°C; annealed at 350°C for 2h to obtain Fe 2 o 3 QDs / g-C 3 N 4 Photo-Fenton catalyst.

Embodiment 2

[0026]First, dissolve 2.0g melamine and 2.0g cyanuric acid in 100mL ultrapure water and stir for 12h; then transfer the above solution to a glass dish and dry at 60°C for 12h; After annealing for 4 hours, a yellowish 3D porous g-C 3 N 4 sample. Take 1.5g of the above 3D porous g-C 3 N 4 Disperse the sample in 100mL ethanol, stir magnetically for 2h to achieve uniform dispersion to obtain g-C 3 N 4 Ethanol dispersion, add 0.27g FeCl to the above dispersion 3 ·6H 2 O and 0.24gNH 4 HCO 3 And stirred for 12h, the product was centrifuged, washed, and dried overnight at 60°C; annealed at 350°C for 2h to obtain Fe 2 o 3 QDs / g-C 3 N 4 Photo-Fenton catalyst.

Embodiment 3

[0028] Get 80mL concentration and be 20mg / L RhB solution, add the Fe prepared in embodiment 2 again 2 o 3 QDs / g-C 3 N 4 Light Fenton catalyst, stirred in dark light for 10min, sampled and filtered for analysis, then added 1.5mL of hydrogen peroxide (H 2 o 2 , 30wt%), turn on the light source, start timing, take samples and filter at 20min, 40min, 60min, and 80min for analysis. After reacting under visible light for 60min, the removal rate of RhB in the solution is greater than 99%. For details, see Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com