Light crushing arm platform car with front wheel chain and rear wheel chain independently driven on two sides

An independent drive, front and rear wheel technology, applied in the direction of wheels, vehicle components, non-deflectable wheel steering, etc., can solve problems such as difficulty in effectively completing mine tunnels, and difficulty in considering volume, weight and stability of construction vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

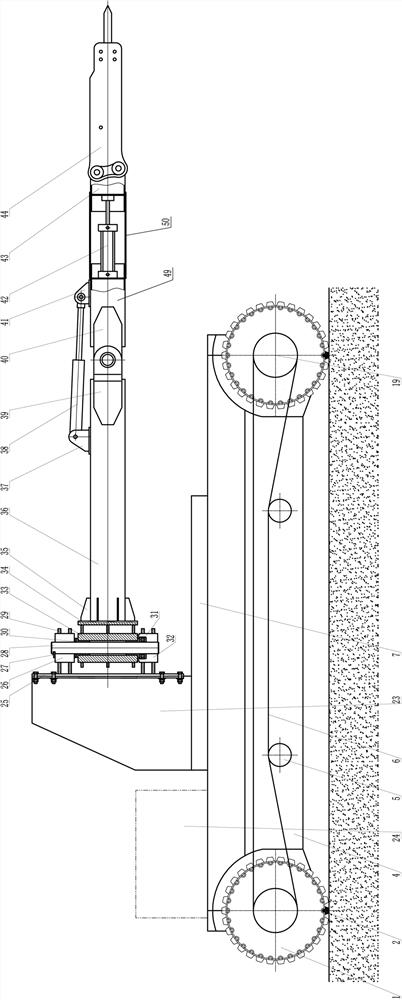

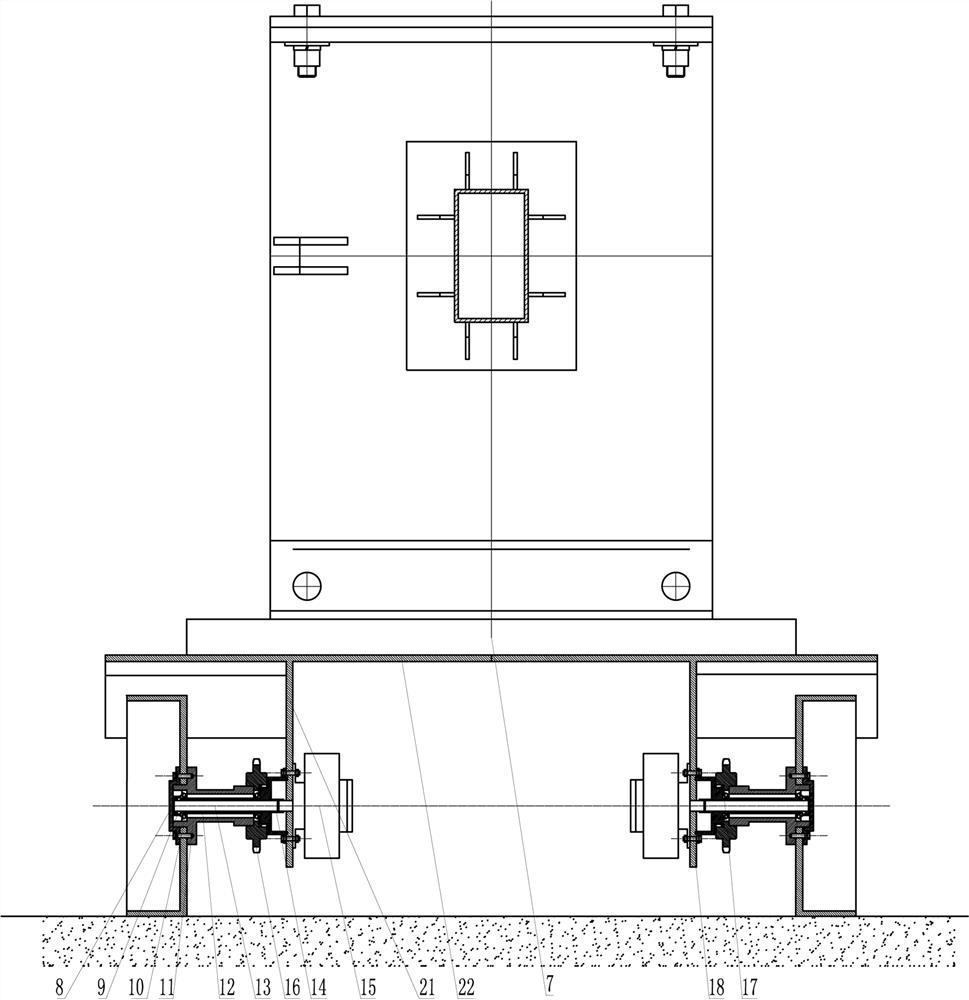

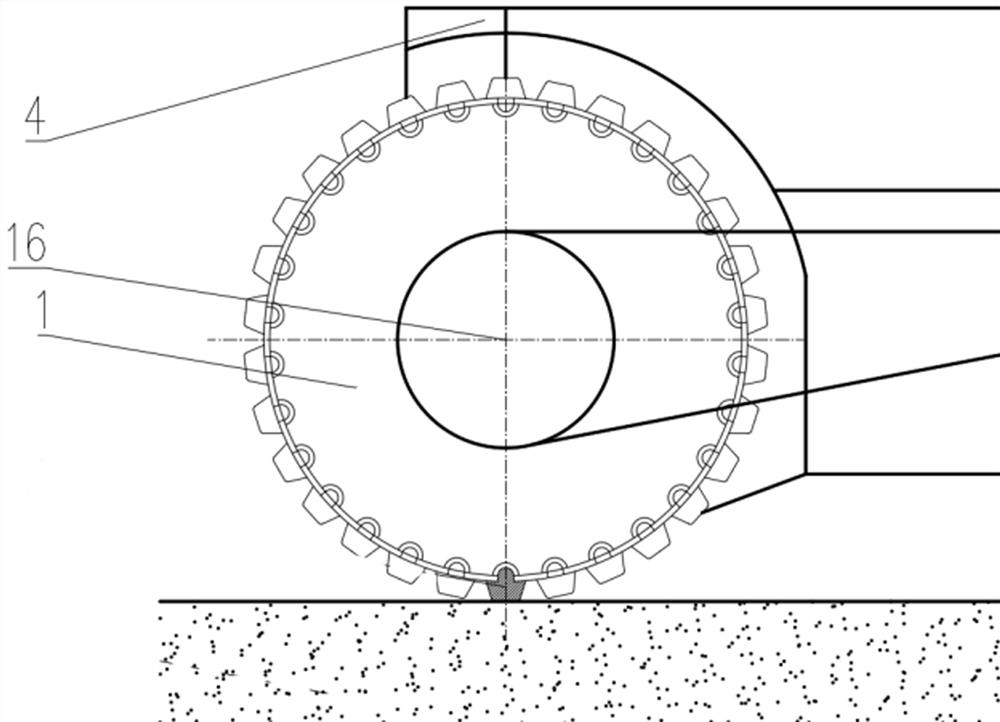

[0030] Such as Figure 1~Figure 8 Among them, a light-duty crushing arm platform truck independently driven by front and rear wheel chains on both sides, including a chassis 4, a walking component assembly is arranged on both sides of the chassis 4, and a power component assembly is arranged on the inner wall of the chassis 4 to cooperate with the walking component assembly; 4 The upper surface is connected with the crushing arm assembly 23 and the control valve installation assembly 24; the chassis 4 includes two parallel side plates 21 and the top plate 22 connected to the top of the side plates 21, and the inner side of the side plates 21 is fixedly connected with the bottom beam; The component assembly includes a driving wheel 1 and a driven wheel 2, which are connected by a chain transmission mechanism; the power component assembly includes a hydraulic motor 15 installed on the inner surface of the side plate 21, and the output end of the hydraulic motor 15 is connected to...

Embodiment 2

[0044] The working principle of the present invention is as follows: the two inner electromagnetic hydraulic motors 15 of the engineering chassis 4 are independently driven by the hydraulic control valve installation assembly 24 to drive the transmission shaft 13, the steel driving wheel 1 and the locking disc 8 on it to rotate respectively At the same time, it drives the driving sprocket 16 to rotate, and drives the passive sprocket 19 to rotate through the tension wheel 5 and the chain, and finally drives the steel passive wheel 2 to rotate. The control valve installation assembly 24 adjusts and controls the synchronous steering of the steel driving wheel 1 and the steel passive wheel 2 on both sides of the engineering chassis 4, and adjusts the rotational speed so that the engineering chassis 4 advances or retreats, using the hydraulic control valve installation assembly 24 The hydraulic motors 15 on both sides are controlled to generate a rotational speed difference, thereb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com