Weld seam tracking visual sensor

A visual sensor and sensor technology, applied in the field of visual sensors, can solve problems such as difficult maintenance, excessive smoke and dust, and poor heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

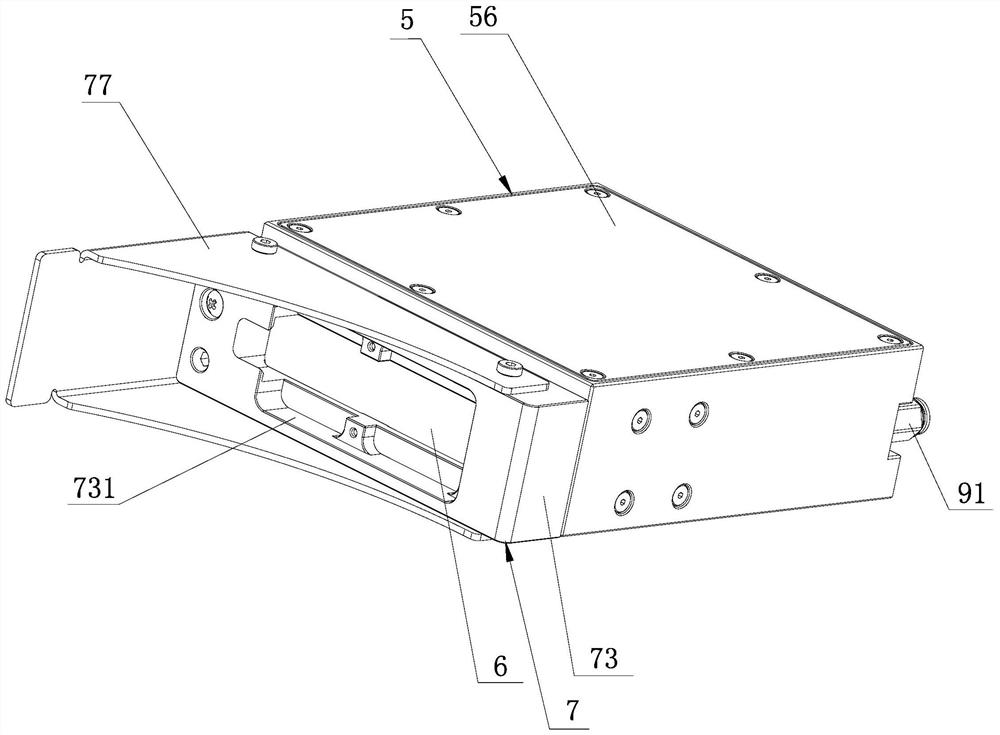

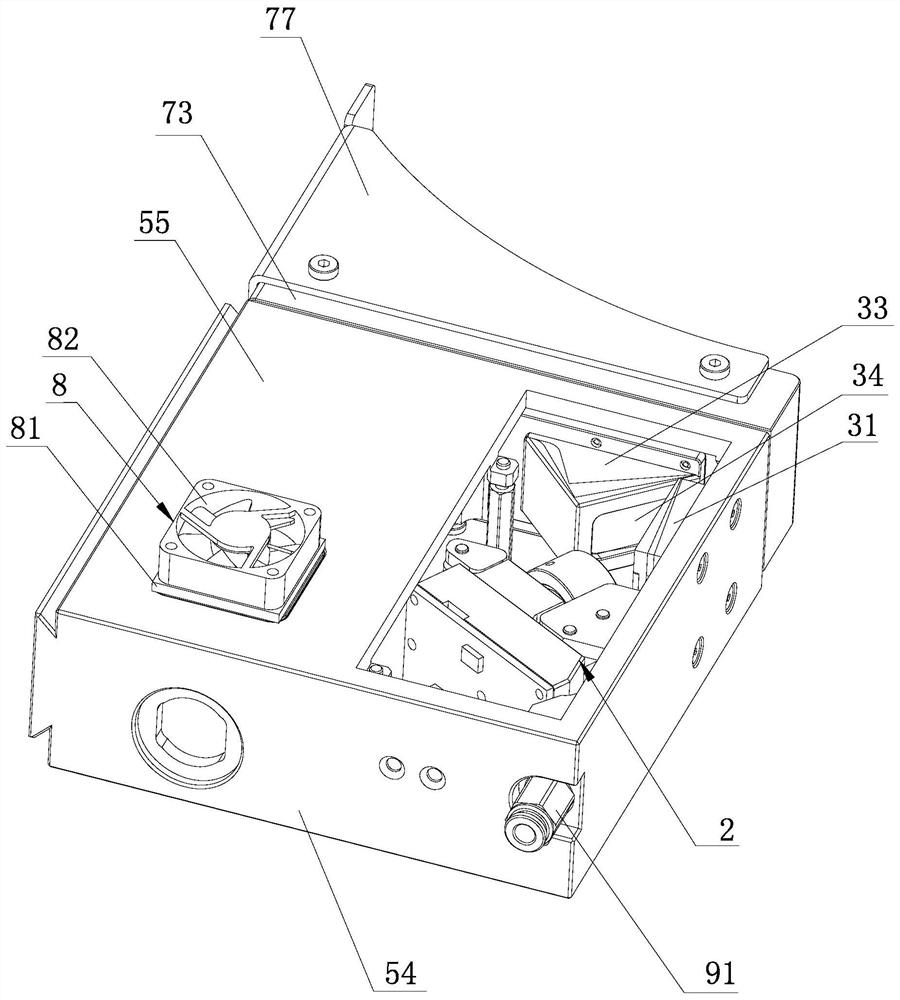

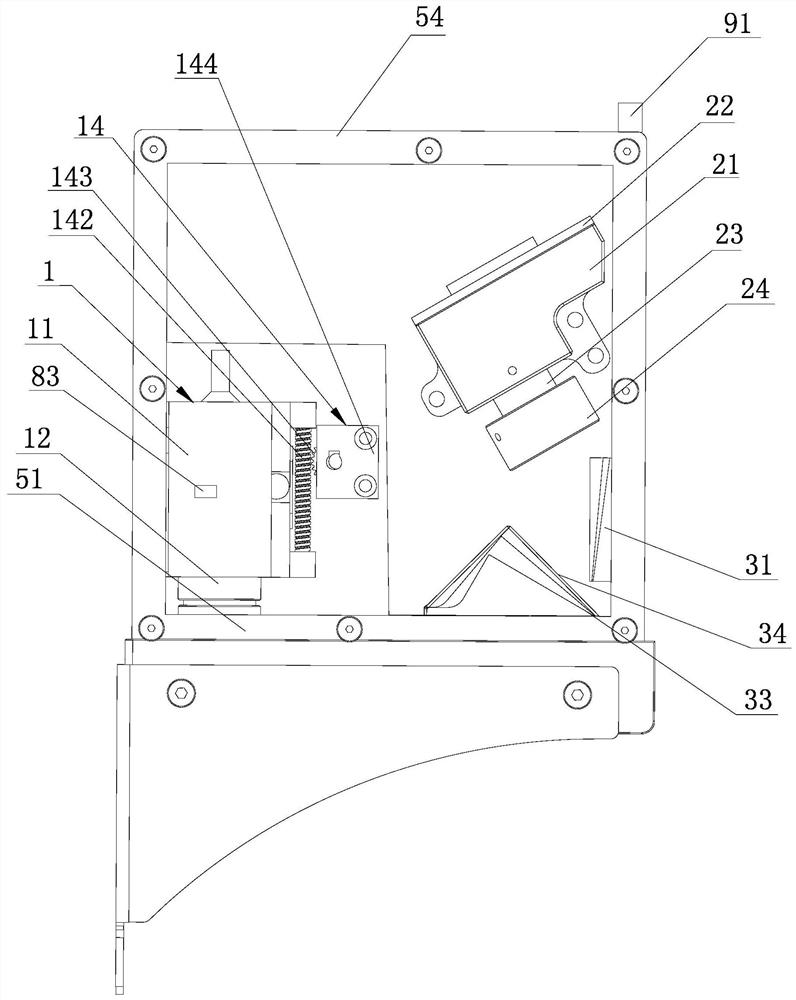

[0040] A welding seam tracking vision sensor proposed by the present invention, as shown in the figure, includes: a laser emitting module 1, which is used to emit structured light to the workpiece that needs to be tracked along the plane intersecting the weld seam of the workpiece, so as to The laser weld image is formed on the plane where the weld of the workpiece intersects; the image acquisition module 2 is used to collect the laser weld image formed on the plane intersected with the weld of the workpiece; the optical reflection module 3 uses light reflection The laser weld image formed on the plane intersecting the weld seam of the workpiece is accurately injected into the image acquisition module 2; The image is processed to facilitate seam tracking; the sensor housing 5, the laser emitting module 1, the image acquisition module 2, the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com