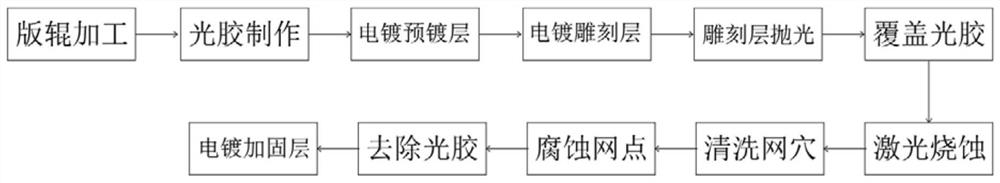

Plate making process of intaglio roller

A gravure printing plate roller and process technology, which is applied to the plate making technology field of the gravure printing plate roller, and can solve the problems of uneven surface and irregular circumference of the plate-making plate roller.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Example: such as figure 1 Shown, a kind of plate-making process of gravure plate roll, comprises the steps:

[0036] (1) Plate roller processing: The base of the plate cylinder is made of seamless steel pipe, the weight is 10KG to 300KG, and the wall thickness of the steel pipe is 10MM to 30MM.

[0037] S1: use the coaxial frame to grind and polish the outer wall of the plate roller;

[0038] S2: cleaning the polished version roller with cleaning solution;

[0039] S3: Use a dry rag to wipe the plate roller, and put it into a drying room for drying at a temperature of 55°C to 75°C.

[0040] (2) Production of light glue: light glue includes 1%~15% of burning resin, 1%~15% of adhesion promoter, 1%~15% of black color paste, 30%~70% of solvent, and 1%~ of plasticizer 3%, leveling agent 1%~3%, defoamer 1%~3%, burnable resin including nitrocellulose and rosin.

[0041] S1: Add half a portion of alcohol ether solvent to the mixer, add all the alcohol ether solvent ablative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com