SF6 gas filling device

An inflatable device, gas technology, applied in the direction of gas/liquid distribution and storage, container filling methods, fixed capacity gas storage tanks, etc., can solve the problems of inconspicuous, falling, not fast, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

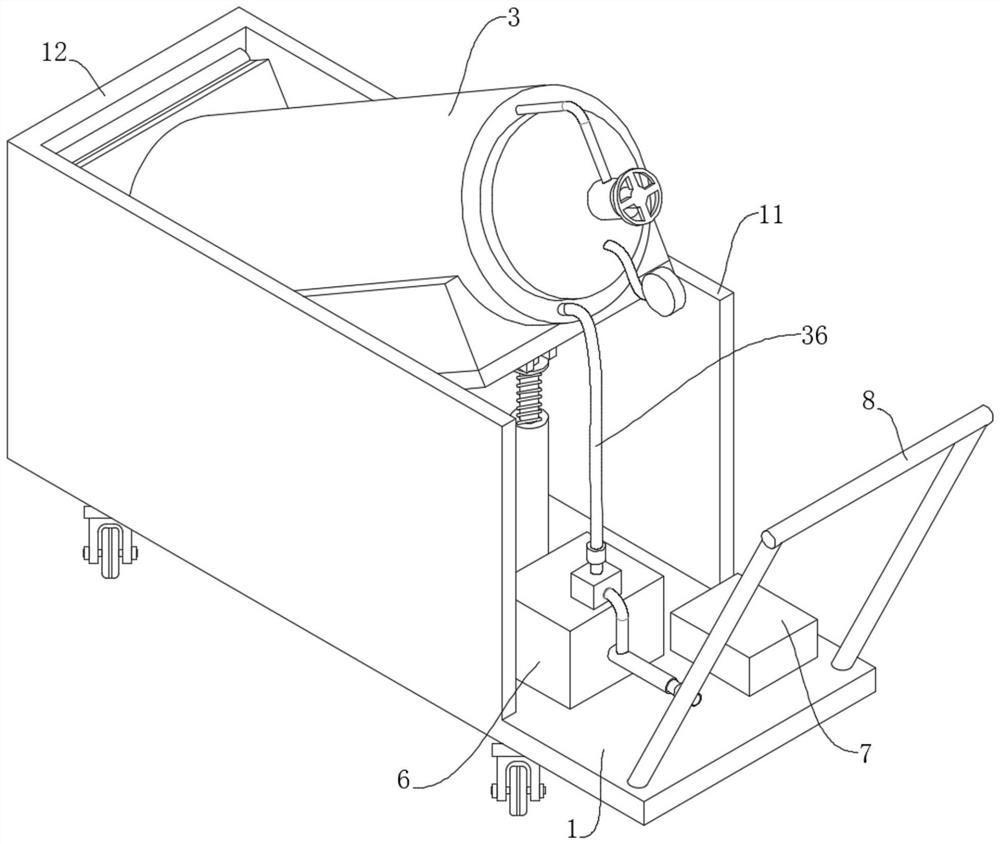

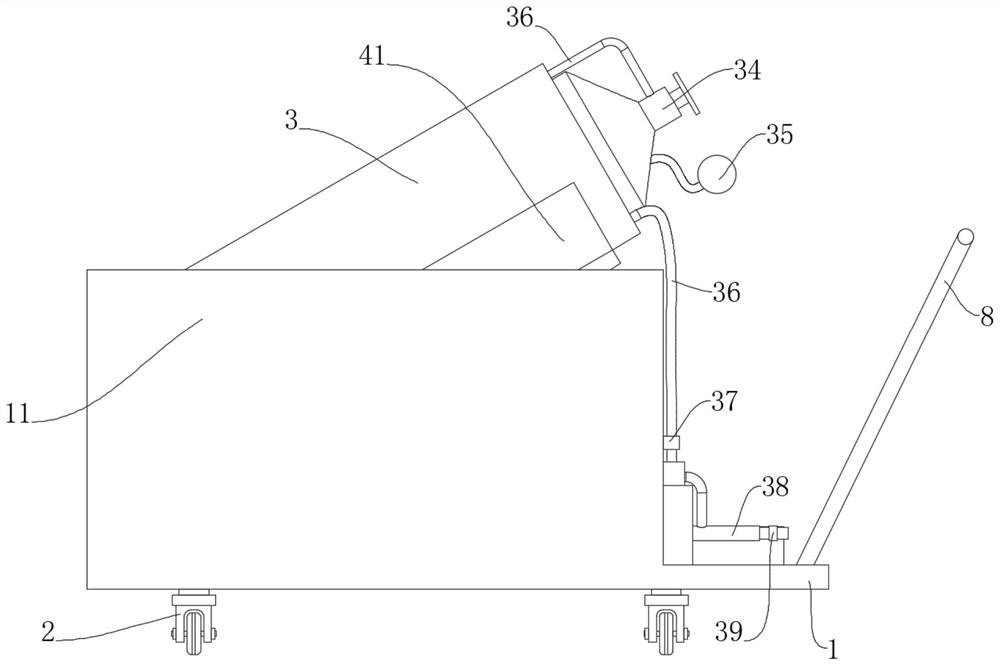

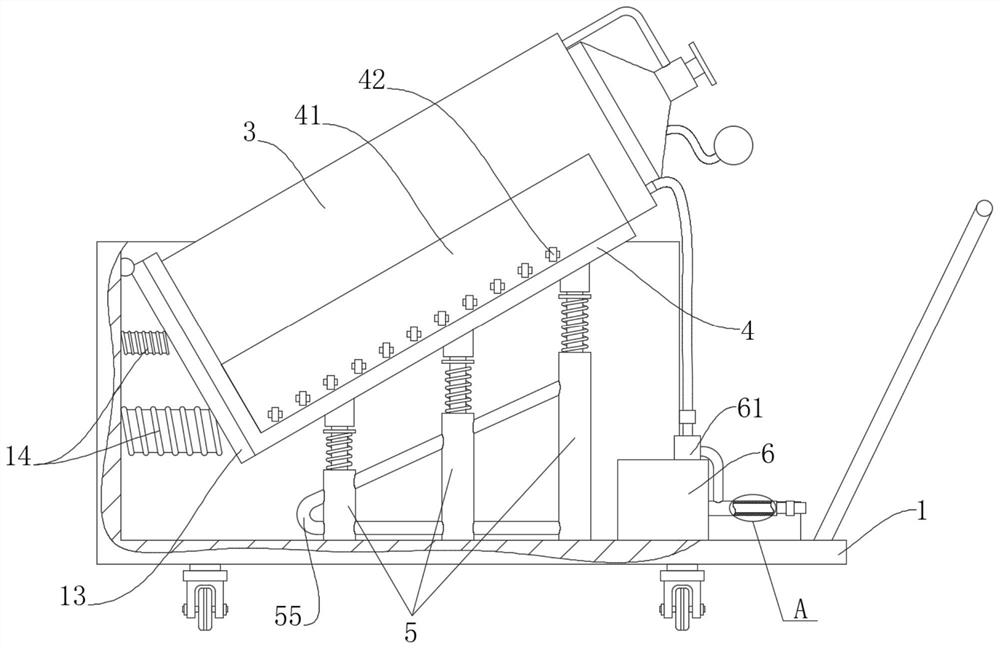

[0028] see Figure 1 to Figure 6 .

[0029] A kind of SF6 gas inflating device of the present invention comprises base 1, a plurality of castors 2 arranged under said base 1 and an inflatable bottle 3 arranged on said base 1, said inflatable bottle 3 includes a tank for storing SF6 gas The inner bottle body 31 and the outer bottle body 32 arranged outside the outer peripheral surface of the inner bottle body 31, there is a gap between the inner bottle body 31 and the outer bottle body 32, and the second bottle body is evenly distributed in the gap. A heating wire 33 is filled with heat conduction oil or water or other heat transfer medium, preferably, because of the large specific heat capacity of water, low price, and because the temperature of water will not rise to make the water boil when heated, so water is selected as a heat transfer m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com