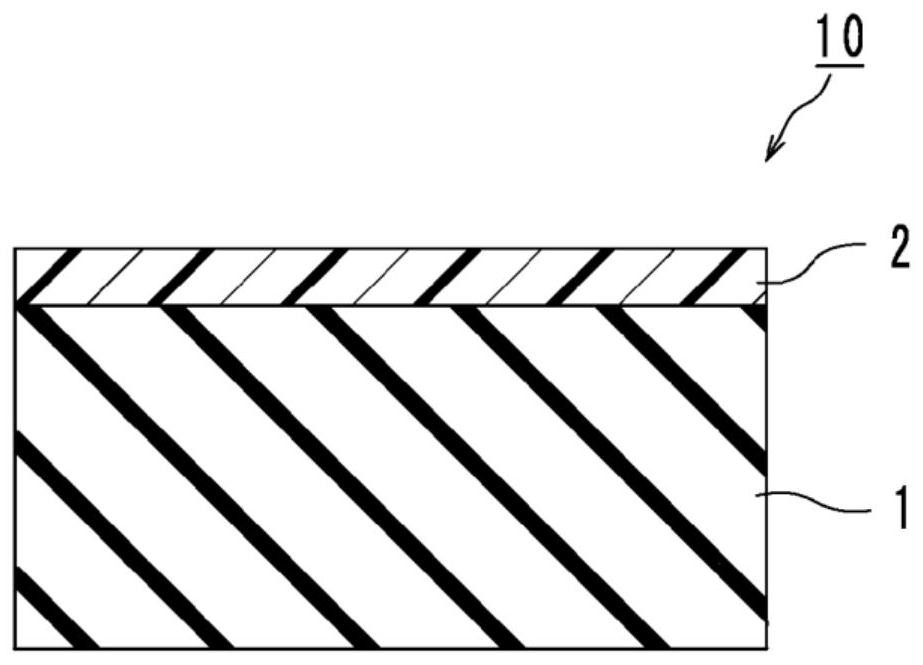

Surface protective film

A technology for protecting films and adhesive layers, applied in the direction of pressure-sensitive films/sheets, film/sheet-like adhesives, adhesive types, etc. Insufficient grade of light peelability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0317] [Example 1]: Manufacture of adhesive composition (1) and surface protection film (1)

[0318] To the solution of the acrylic copolymer (1) obtained in Production Example 1, an organosiloxane ( KF-353, manufactured by Shin-Etsu Chemical Co., Ltd.) diluted to 10% by weight solution: 2 parts by weight (0.2 parts by weight in terms of solid content), bis(tris) as an antistatic agent, alkali metal salt (ionic compound) Lithium fluoromethanesulfonyl)imide (LiN(CF 3 SO 2 ) 2 : LiTFSI, manufactured by Tokyo Chemical Industry Co., Ltd.): 0.15 parts by weight, isocyanate-based crosslinking agent (trade name "CORONATE HX", manufactured by Tosoh Corporation): 3.4 parts by weight, as a crosslinking catalyst 0.006 parts, EMBILIZER OL-1 (manufactured by Tokyo Fine Chemical CO., LTD.): 0.01 parts, a solution of the methacrylic copolymer (2) obtained in Production Example 2, which is 0.2 parts by weight in terms of solid content, and then A polyoxyalkylene glycol compound (SANNIX G...

Embodiment 2

[0321] [Example 2]: Manufacture of adhesive composition (2) and surface protection film (2)

[0322] The amount of CORONATE HX was changed to 8.1 parts by weight in terms of solid content, and the amount of GP250 was changed to 3 parts by weight. In the same manner as in Example 1, an adhesive composition (2) and a surface Protective film (2).

[0323] The results are shown in Table 1.

Embodiment 3

[0324] [Example 3]: Manufacture of adhesive composition (3) and surface protection film (3)

[0325] The amount of CORONATE HX was changed to 12.8 parts by weight in terms of solid content, and the amount of GP250 was changed to 5 parts by weight. In the same manner as in Example 1, an adhesive composition (3) and surface Protective film (3).

[0326] The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com