Preparation method of adsorption type piezoelectric photocatalytic composite fiber material

A composite fiber and piezoelectric fiber technology, which is applied in catalyst activation/preparation, chemical instruments and methods, water treatment of special compounds, etc., can solve the problems of poor adsorption performance and high carrier recombination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

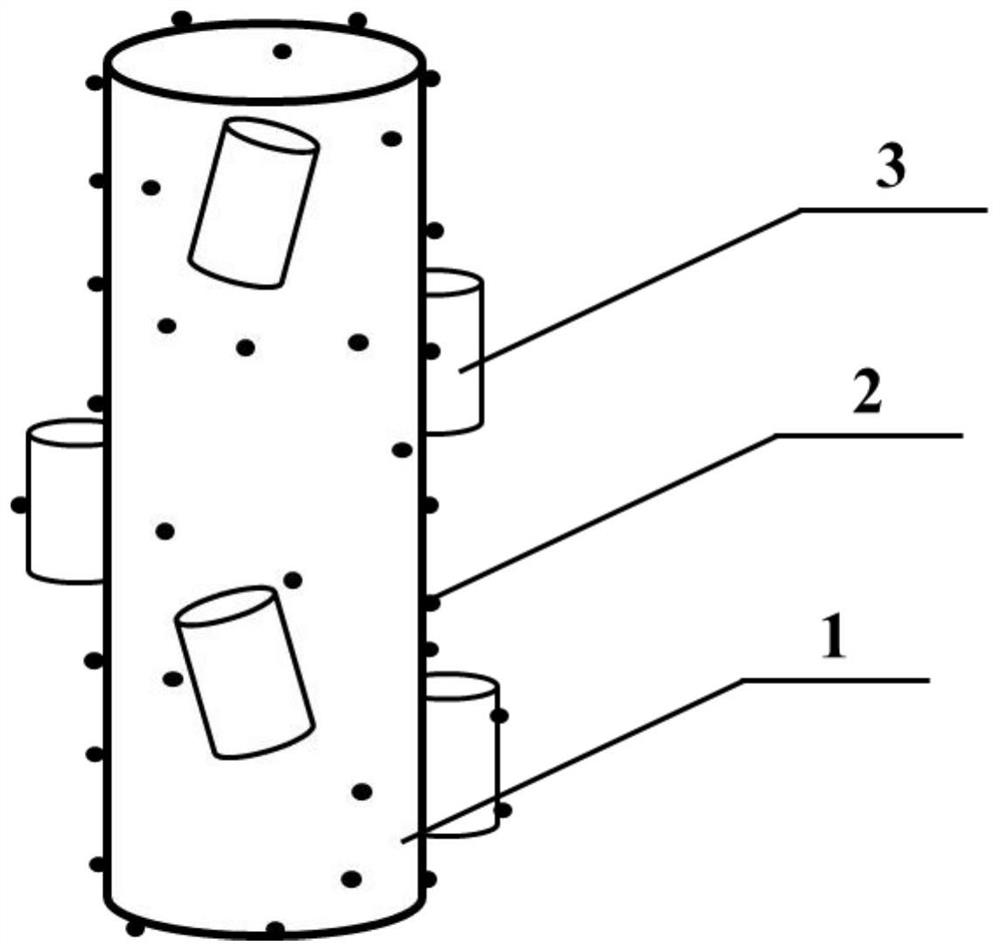

Image

Examples

Embodiment 1

[0059] 7.56g melamine (C 3 N 6 h 6 ) and 7.42g boric acid (H 3 BO 3 ) were dissolved in 500 mL distilled water and mixed to form a uniform precursor solution. Heat and stir the precursor solution in a water bath at 95°C for 4 hours until the solution becomes transparent, insert the ultrasonic probe of the cell pulverizer into the solution, adjust the ultrasonic power to 100W, and ultrasonic frequency to 40KHz for 2 hours, and naturally After cooling, place it in an oven at 90°C for 4 hours, then place it in a tube furnace, select a sintering temperature of 1100°C under a nitrogen atmosphere, a heating rate of 5°C / min, and a sintering time of 8 hours for calcination to obtain white BN fiber; secondly, the obtained white BN fiber is added into isopropanol to form a mixed solution, and then the mixed solution is placed in an ultrasonic probe of a cell pulverizer at an ultrasonic power of 100W and an ultrasonic frequency of 40KHz for 48h, and finally filtered, in Dry in an ov...

Embodiment 2

[0065] 5.154g melamine (C 3 N 6 h 6 ) and 5.051g boric acid (H 3 BO 3 ) were dissolved in 500 mL distilled water and mixed to form a uniform precursor solution. Heat and stir the precursor solution in a water bath at 90°C for 4 hours until the solution becomes transparent, insert the ultrasonic probe of the cell pulverizer into the solution, adjust the ultrasonic power to 100W, and ultrasonic frequency to 40KHz for 2 hours, and naturally After cooling, place it in an oven at 85°C for 4 hours, then place it in a tube furnace, select a sintering temperature of 1200°C under a nitrogen atmosphere, and a heating rate of 5°C / min; sintering time of 7 hours for calcination to obtain white BN fiber; secondly, the obtained white BN fiber is added into isopropanol to form a mixed solution, and then the mixed solution is placed in an ultrasonic probe of a cell pulverizer at an ultrasonic power of 100W and an ultrasonic frequency of 40KHz for 48h, and finally filtered, in Dry in an ov...

Embodiment 3

[0071] 2.551g melamine (C 3 N 6 h 6 ) and 2.5g boric acid (H 3 BO 3 ) were dissolved in 500 mL deionized water and mixed to form a uniform precursor solution. Heat and stir the precursor solution in a water bath at 85°C for 4.5h until the solution becomes transparent, insert the ultrasonic probe of the cell pulverizer into the solution, adjust the ultrasonic power to 200W, and ultrasonic frequency to 40KHz for 1.5h. After being cooled naturally under natural conditions, it was dried in an oven at 80°C for 5 hours, and then placed in a tube furnace. Under a nitrogen atmosphere, the sintering temperature was selected to be 1300°C, and the heating rate was 5°C / min; the sintering time was 6 hours for calcination to obtain White BN fiber; secondly, add the obtained white BN fiber into isopropanol to form a mixed solution, then place the mixed solution in the ultrasonic probe of a cell pulverizer, ultrasonicate for 48 hours at an ultrasonic power of 200W, and an ultrasonic frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com