A high adsorption and penetration type coating device for steel strip processing

A coating device, high adsorption technology, applied in spraying device, device for coating liquid on the surface, coating, etc., can solve the problems affecting the quality and service life of the steel strip, poor uniformity of the paint surface, and small adhesion , to achieve the effect of enhancing the coating effect, improving the metal texture and preventing peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

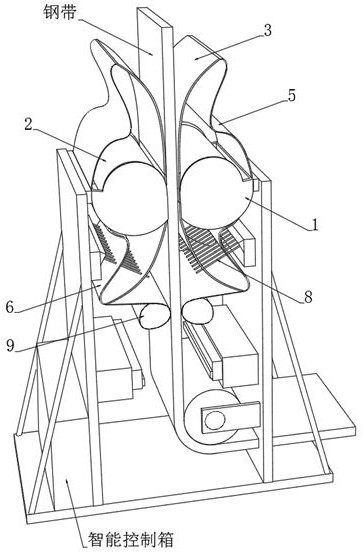

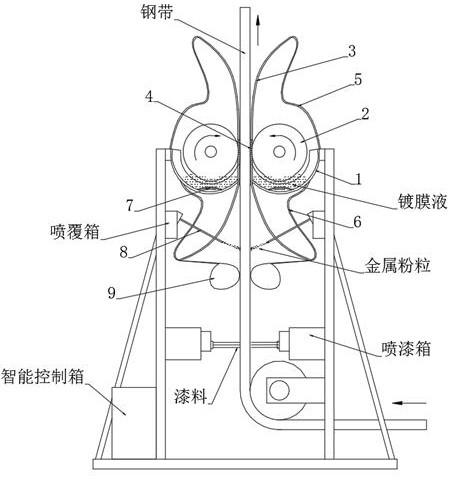

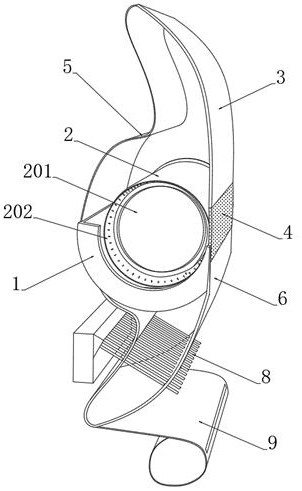

[0043] see Figure 1-2 , a high-adsorption-penetrating coating device for steel strip processing, including a control console, a paint spray box is installed on the opposite side wall near the bottom end of the control console, a paint spray nozzle is arranged on the paint spray box, and a pair of immersion liquids are fixedly installed on the upper end of the control console Cylinder base 1, a pair of immersion cylinder bases 1 are equipped with brushing sleeve rollers 2 for rotation, and a motor for driving the brushing sleeve rollers 2 is installed on the outer end wall of the immersion cylinder base 1. A pair of brushing sleeves A steel strip coating chamber is reserved between the rollers 2, and the steel strip is pulled upward from the steel strip coating chamber from bottom to top. The control console is equipped with guide rollers for steel strip traction and guidance, and a pair of coating rollers 2 are symmetrically distributed on the steel strip. On both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com