Wrapping cloth V belt automatic demolding device

A technology of automatic demoulding and wrapping, which is applied to belts, household appliances, other household appliances, etc., can solve the problems of mechanization, poor automation, labor-intensive assembly and disassembly of workers, and many auxiliary processes of vulcanization round mold devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

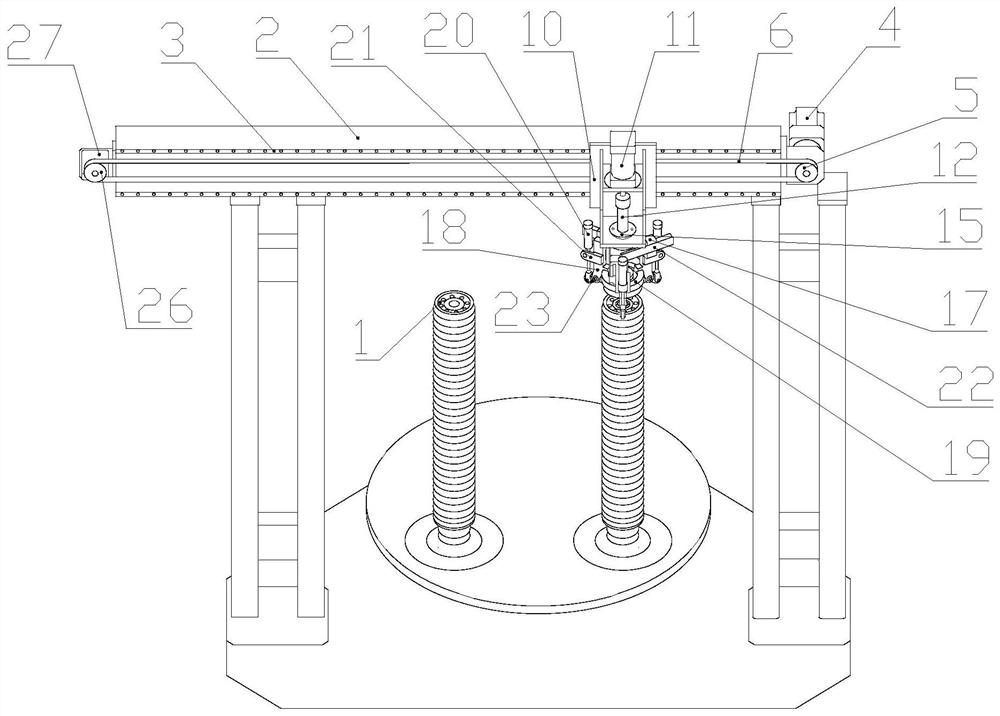

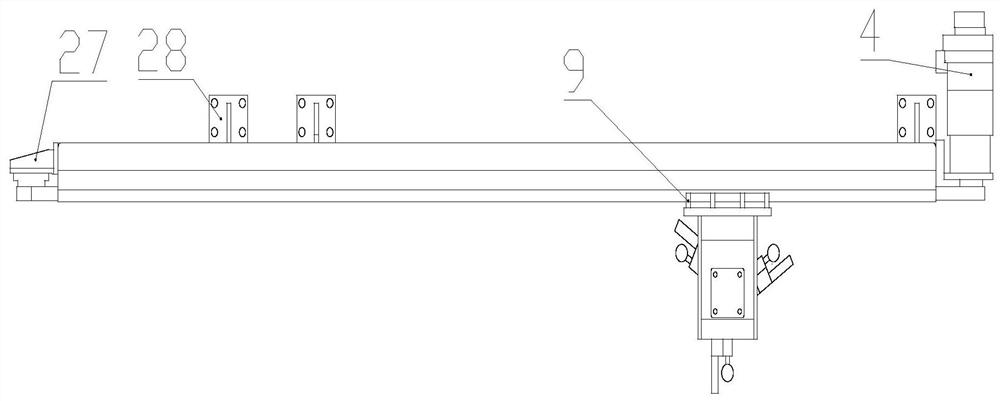

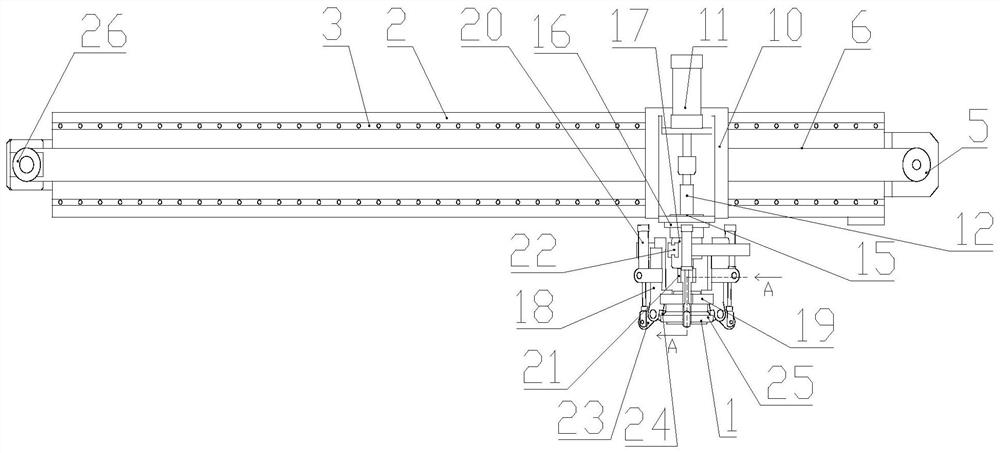

[0019] refer to figure 1 , the present invention provides a new type of cloth V-belt automatic demoulding device, which consists of a round mold 1, a guide rail bracket I2, a guide rail I3, a motor 4, a timing belt pulley I5, a timing belt 6, a belt fixing seat 7, a belt support Seat 8, slider 9, lifting seat 10, cylinder I11, mandrel 12, magnet connection seat 13, electromagnet 14, copper sleeve 15, lifting sliding seat 16, guide seat 17, fixed belt seat 19, cloth V-belt 25 , synchronous pulley II 26, pulley seat 27, guide rail bracket II 28, and a grasping hand, which includes fixed seat jaws 18, cylinder II 20, cylinder seat grasping 21, guide rail II 22, jaws I 23, jaws II24, the guide rail bracket I2 is fixedly connected to the guide rail I3, the motor 4 is fixedly connected to the guide rail bracket I2, the synchronous pulley I5 is fixedly connected to the motor 4, and the pulley seat 27 is fixedly connected to the guide rail bracket I2, and the synchronous pulley II5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com