Femtosecond laser double-pulse glass welding strength enhancing system device

A technology of femtosecond laser and welding strength, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., and can solve the problem of low glass welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

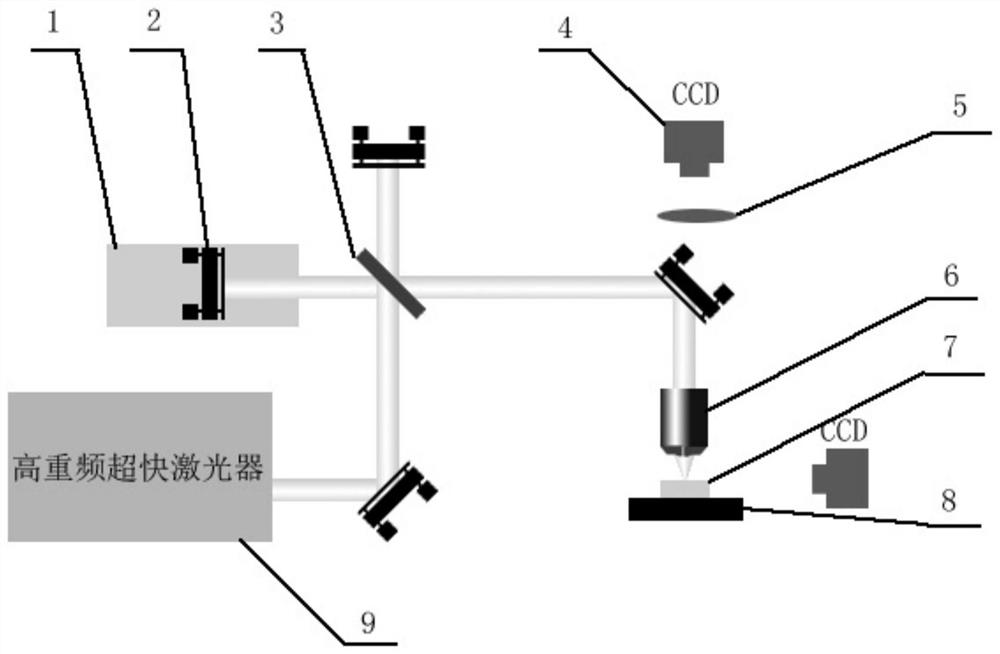

[0016] refer to figure 1. In the preferred embodiment described below, a femtosecond laser double-pulse glass welding strength enhancement system device includes: a total reflection mirror 2 fixed on an electronically controlled one-dimensional motion platform 1, set on a high repetition rate ultrafast laser 9 The front end, the first 45° total reflection mirror on the inclined surface symmetrically distributed by the 45° inclined mirror and the half-transparent half-mirror 3 corresponding to the total reflection mirror 2 form a figure-eight "]" shaped optical path total reflection mirror group, corresponding to The top-view total reflection mirror above the back end of the semi-transparent mirror 3 is fixed on the electronically controlled three-dimensional motion platform 8 and the two stacked glass products 7 to be processed are monitored online through the lens 5 and the objective lens 6. CCD charge-coupled element 4 and lateral CCD charge-coupled element 4, wherein: the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com