Heat-resistant engineering plastic and preparation method thereof

An engineering plastic and heat-resistant technology, which is applied in the field of heat-resistant engineering plastic and its preparation, can solve problems such as insufficient strength and poor heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

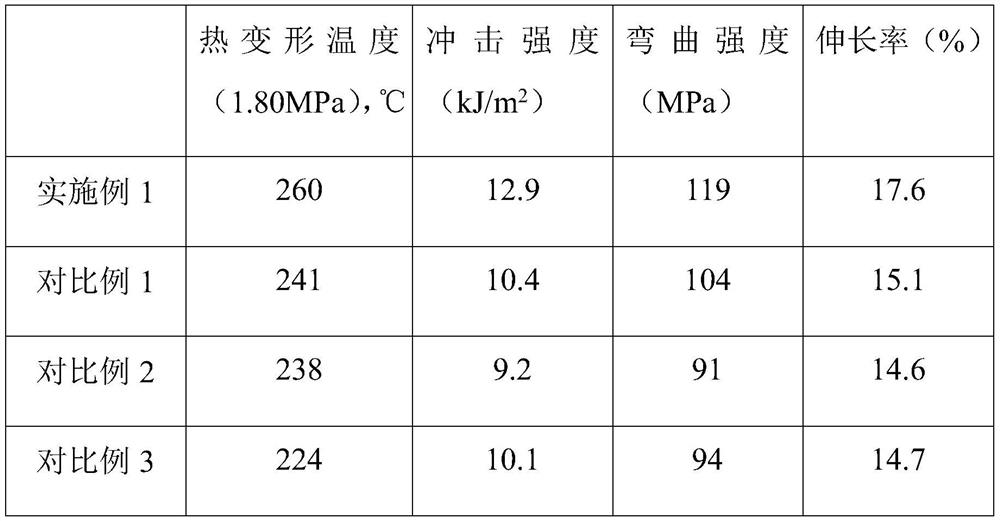

Examples

preparation example Construction

[0043] In the second aspect of the present invention, the engineering plastics produced by a method for preparing heat-resistant engineering plastics mainly include the following raw materials in parts by weight: 70-140 parts of N-methylpyrrolidone, 20-40 parts of xylene, 10-20 parts N-N dimethylacetamide, 30-60 parts of N-N dimethylformamide, 40-60 parts of self-made lubricant, 40-60 parts of titanium dioxide.

[0044] Preferably, the self-made lubricant is prepared by alkali treatment of titanium dioxide.

Embodiment 1

[0045] Embodiment 1: heat-resistant engineering plastics one:

[0046] A heat-resistant engineering plastic, mainly comprising:

[0047] 70 parts of N-methylpyrrolidone, 20 parts of xylene, 10 parts of N-N dimethylacetamide, 30 parts of N-N dimethylformamide, 40 parts of self-made lubricant, 40 parts of titanium dioxide.

[0048] The preparation method of this engineering plastics is as follows:

[0049](1) Mix N-methylpyrrolidone, xylene, N-N dimethylacetamide, and N-N dimethylformamide in a volume ratio of 7:2:1:3, and stir at 90°C for 3 hours to obtain polyamide acid solution;

[0050] (2) Divide the polyamic acid solution into two parts with equal volumes, one part is wet-spun, the polyamic acid solution passes through the spinning hole, the coagulation bath, and after natural coagulation, the polyamic acid solution is dried, wound and screened to obtain the polyamic acid solution. Amic acid primary staple fiber, the diameter of the silk hole during wet spinning is 1.2m...

Embodiment 2

[0056] Embodiment 2: heat-resistant engineering plastics 2:

[0057] A heat-resistant engineering plastic, mainly comprising:

[0058] 140 parts of N-methylpyrrolidone, 40 parts of xylene, 20 parts of N-N dimethylacetamide, 60 parts of N-N dimethylformamide, 80 parts of self-made lubricant, 80 parts of titanium dioxide.

[0059] The preparation method of this engineering plastics is as follows:

[0060] (1) Mix N-methylpyrrolidone, xylene, N-N dimethylacetamide, and N-N dimethylformamide in a volume ratio of 7:2:1:3, and stir at 120°C for 5 hours to obtain polyamide acid solution;

[0061] (2) Divide the polyamic acid solution into two parts with equal volumes, one part is wet-spun, the polyamic acid solution passes through the spinning hole, the coagulation bath, and after natural coagulation, the polyamic acid solution is dried, wound and screened to obtain the polyamic acid solution. Amic acid primary staple fiber, the diameter of the hole during wet spinning is 2.2mm, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com