Hot-rolled air-cooled bainite high-toughness and high-strength steel sheet with tensile strength larger than or equal to 1300 MPa and manufacturing method therefor

A tensile strength, high-strength steel plate technology, applied in the field of steelmaking, can solve problems such as difficult shaping and poor plate shape, and achieve the effects of cost saving, lightweight corrosion resistance, and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

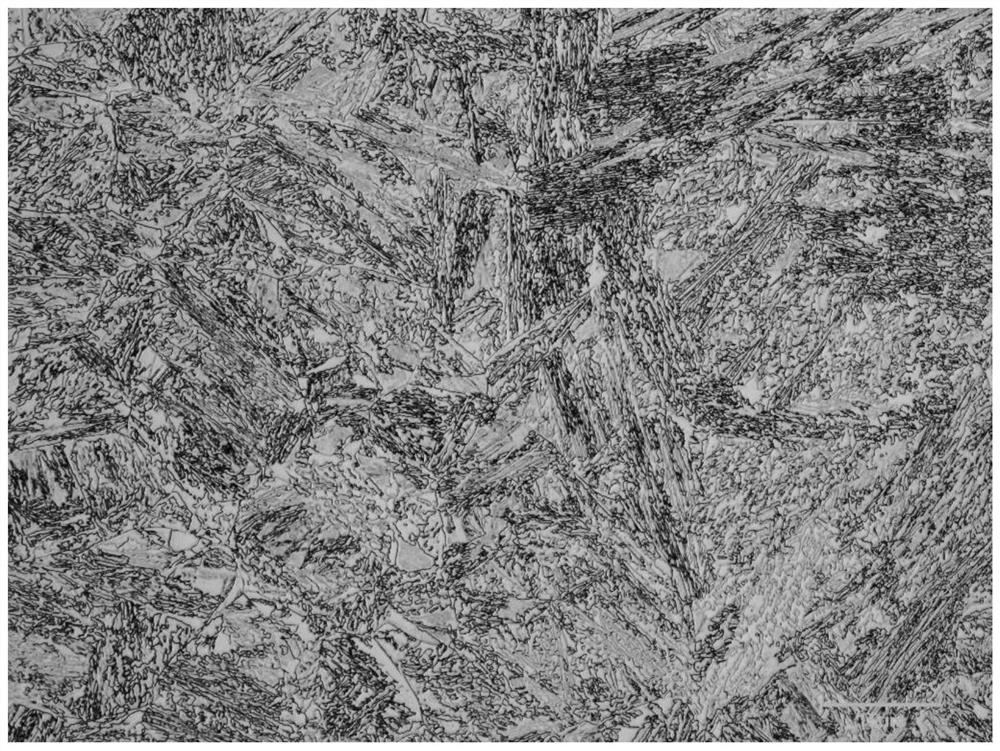

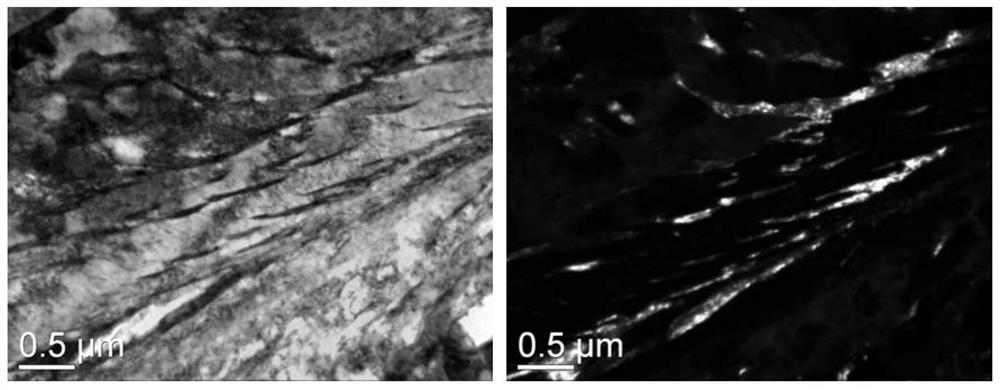

Image

Examples

Embodiment

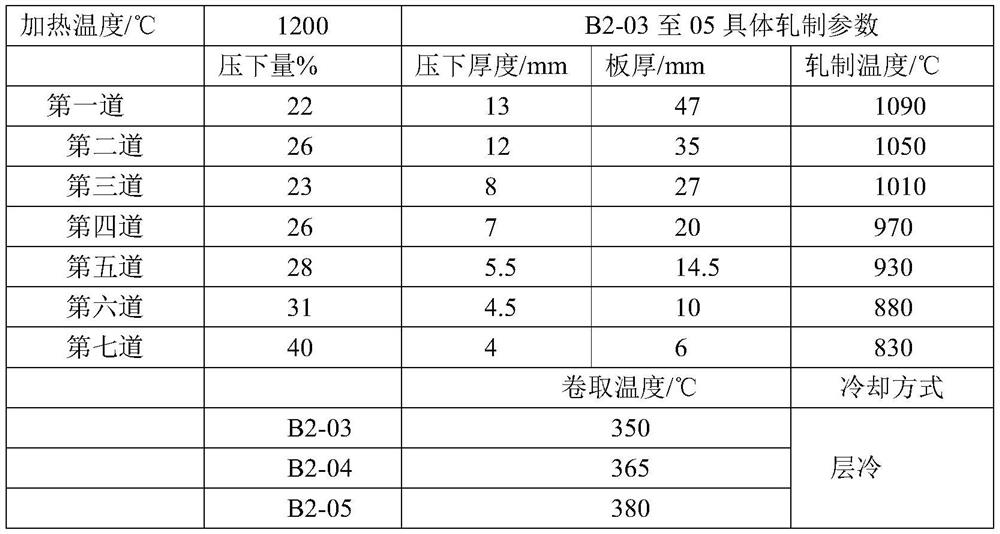

[0030] Manufacture tensile strength ≥ 1300MPa hot-rolled air-cooled bainite high-toughness and high-strength steel plate according to the method of the present invention, the chemical composition and mass percentage of the test steel are as shown in Table 1 (the rest are iron and unavoidable impurities):

[0031] Table 1 Chemical composition of test steel

[0032] C mn Si P S Ti Cr V B 0.25 1.69 1.50 ≤0.010 ≤0.003 0.05 0.79 0.13 0.0020

[0033] 1. Steelmaking

[0034] 1. Hot metal pretreatment process

[0035] S ≤ 0.0030wt.% and P ≤ 0.01wt.% are put into the furnace for pretreatment, and the slag is removed; fine steel scrap is used.

[0036] 2. Converter process

[0037] The converter pulls carbon once and hits to avoid spot blowing; the ladle is purged with argon gas before tapping to control the tapping port and avoid scattered flow.

[0038] 3. Refining process

[0039] The LF+RH dual-path process is adopted, and the gas content is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com