Grooving pipe laying device

A grooving and equipment technology that is applied to mining equipment, earth movers/excavators, earth drilling and mining, etc., and can solve problems such as large manpower and material inputs and low operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

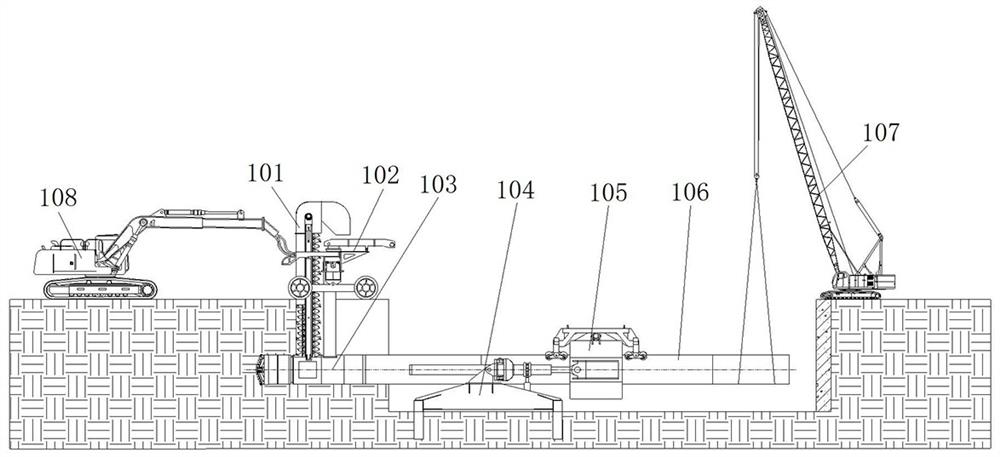

[0044] Such as figure 1 As shown, the grooving pipe laying equipment includes a bucket lifting device 101, a traveling device 102, a driving device 103, an underframe 104, a pipe clamping device 105, a crane 107 and a power unit 108; The device 103, the chassis 104 and the clamping device 105 are all in the originating shaft, the power unit 108 is arranged in front of the originating shaft to provide hydraulic power to each device, and the crane 107 is arranged in the rear of the originating shaft for hoisting pipelines 106; the clamping device 105 is arranged behind the underframe 104 for clamping the pipeline; the excavation device 103 is arranged in front of the underframe 104 for forward excavation; the bucket lifting device 101 and the traveling device 102 are both arranged on the above the device 103.

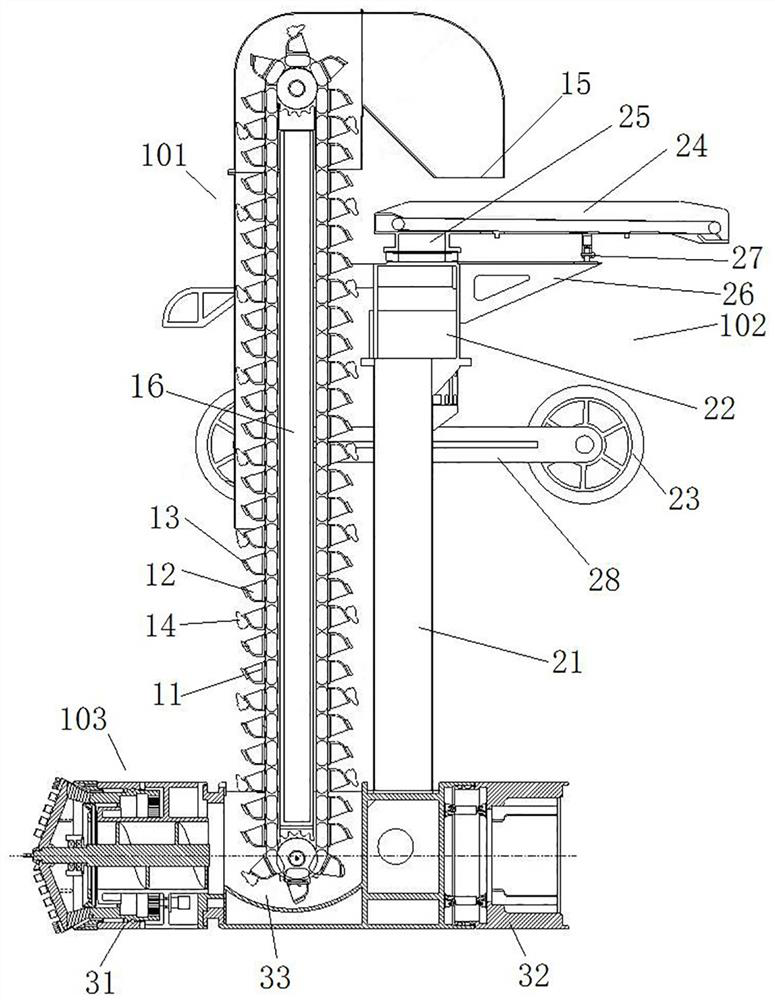

[0045] Such as figure 2 with Figure 4As shown, the excavation device 103 includes a front housing 31 and a rear housing 32, and a deviation correction oil cylinder 3...

Embodiment 2

[0073] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the groove cutting and pipe laying equipment includes a traveling device 102, and the traveling device 103 is connected to the excavation device 103 through the second column 21, and the muck is lifted by the bucket lifting device 101. The slag outlet falls on the slag conveyor belt 24 of the traveling device 102, and falls on one side of the ditch through the slag discharge end of the slag conveyor belt 24. In this embodiment, the groove cutting and pipe laying equipment does not include a traveling device, and the slag outlet of the bucket lifting device is located on one side of the groove.

Embodiment 3

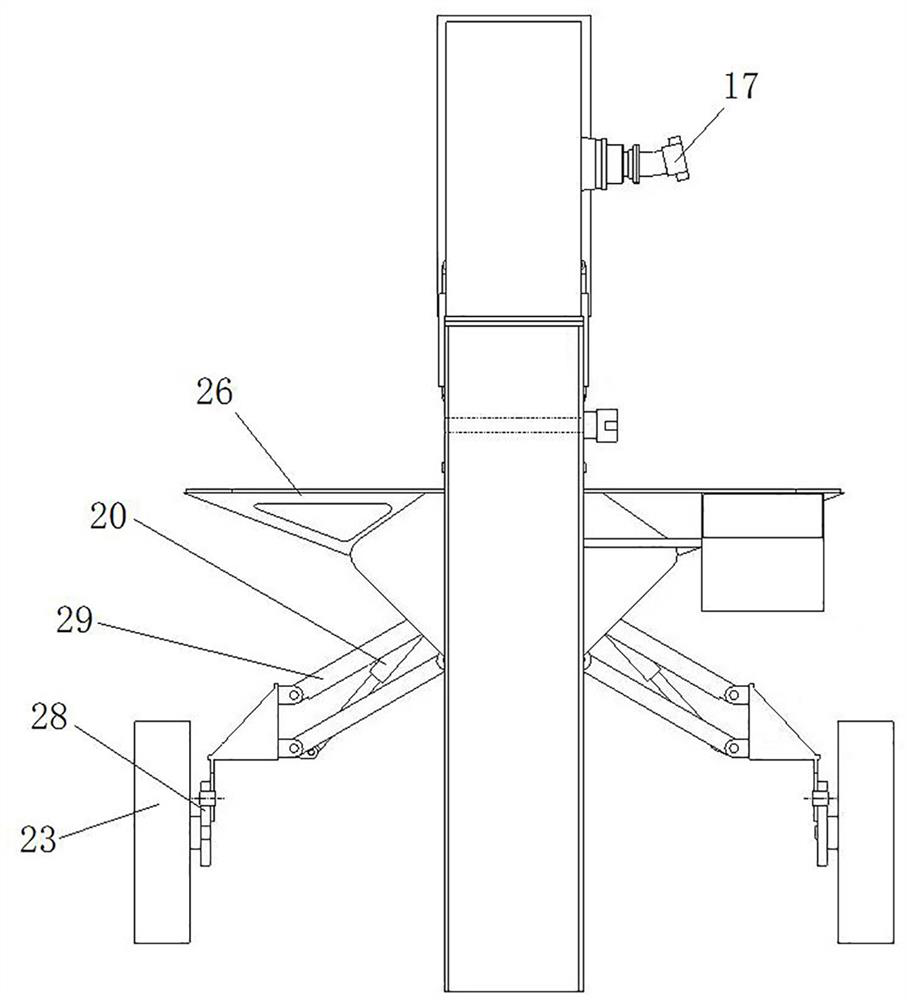

[0075] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, two sets of road wheels 23 are respectively connected to the walking frame 22 through a four-bar linkage mechanism 29, and the walking frame 22 is provided with a road wheel adjustment oil cylinder 20, and the road wheel adjustment The oil cylinder 20 makes the road wheels 22 always be supported on the ground by adjusting the four-bar linkage 29 . In this embodiment, the two sets of walking wheels are vertically slidably assembled on the walking frame, and the walking frame is provided with a walking wheel adjustment oil cylinder, which directly drives the walking wheels to move vertically, so that the walking wheels are always supported on the on the ground.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com