Centralized power-adjustable BMS passive equalization circuit

A passive equalization, centralized technology, applied in charge equalization circuits, current collectors, circuit devices, etc., can solve problems such as low efficiency, complex control, and difficulty in reducing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

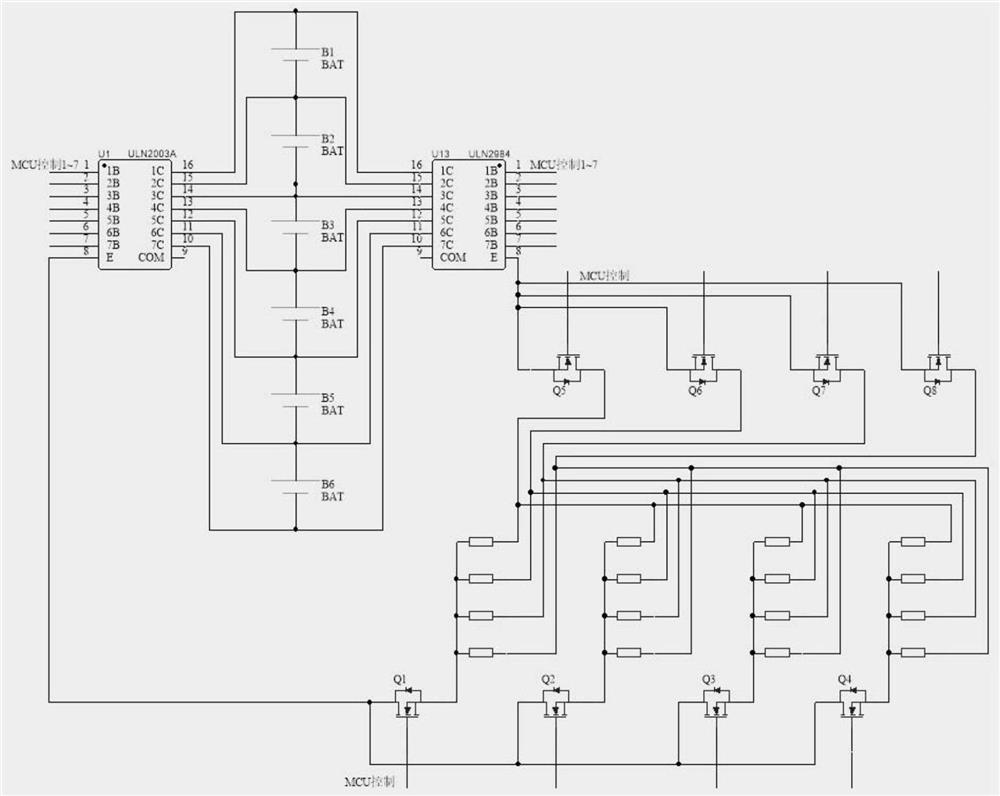

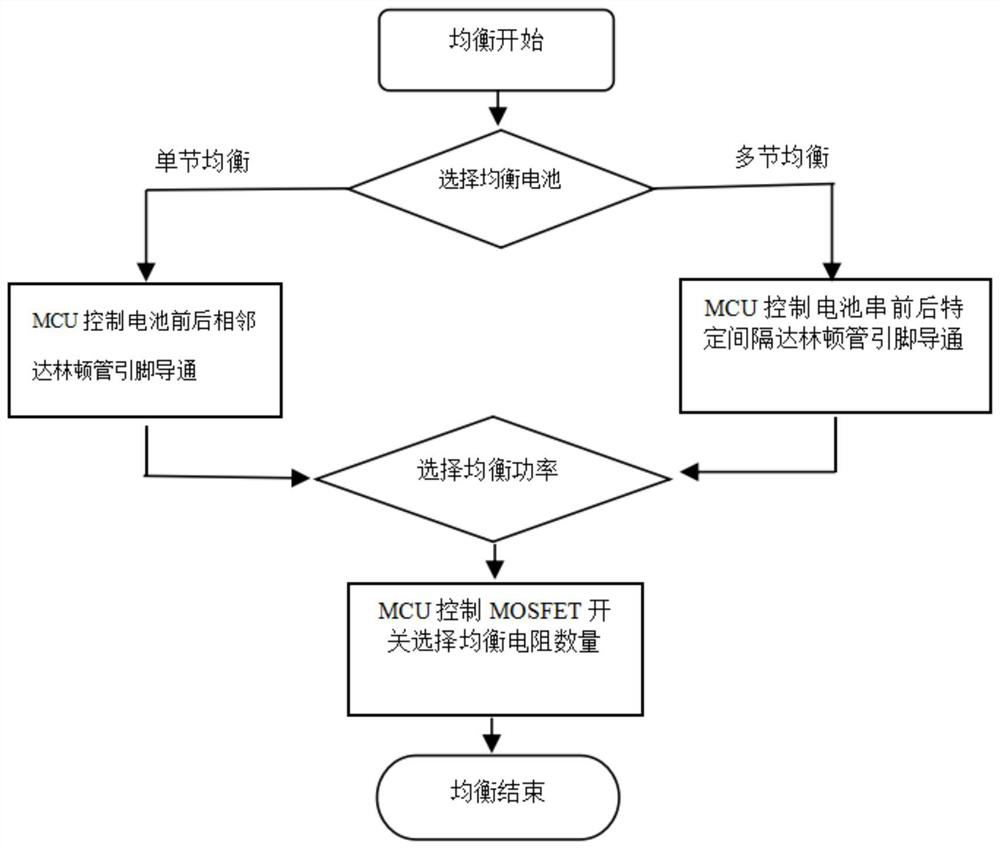

[0027] Embodiment 1: If the MCU judges that battery B3 needs to be balanced, it sends a high level to the 3B pin of the U1 Darlington tube array, and the corresponding 3C pin is turned on, and the positive current of the battery B3 flows from the 3C pin to the E lead The pin flows from the E pin to the balance resistor array. At the same time, the MCU needs to change the high level of the 4B pin of the U2 Darlington tube array to a low level, and the corresponding 4C pin is turned on, and the current of the equalizing resistor array flows from the E pin to the 4C pin, and finally flows back to the Battery B3 negative terminal.

[0028] The single-cell battery balancing method is shown in the above example. The MCU controls the U1 Darlington tube array and the U2 Darlington tube array, connects the pins corresponding to the positive and negative poles of the battery, and connects the battery to the balancing resistor array.

[0029] Multi-cell battery balancing, that is, the M...

Embodiment 2

[0030] Embodiment 2: If the MCU judges that batteries B3 and B4 need to be balanced, a high level is sent to the 3B pin of the U1 Darlington tube array, and the corresponding 3C pin is turned on, and the positive current of the battery B3 flows from the 3C pin to E pin, from the E pin to the balance resistor array. At the same time, the MCU needs to change the high level of the 5B pin of the U2 Darlington tube array to a low level, and the corresponding 5C pin is turned on, and the current of the equalizing resistor array is diverted from E to the 5C pin, and finally flows back to the battery B4 negative pole.

[0031] Two non-adjacent single-cell batteries are balanced, and the microcontroller sends two PWM signals with the same frequency and opposite phases, respectively controlling the Darlington tubes corresponding to the positive and negative poles of the two batteries to be connected, and the two batteries are alternately connected to the balance resistor array.

Embodiment 3

[0032] Embodiment 3: If the MCU judges that batteries B3 and B5 need to be balanced, two PWM signals with the same frequency and opposite phases are sent to the 3B and 5B pins of the U1 Darlington tube array, and the positive currents of batteries B3 and B5 are alternately drawn by 3C The pin and 5C pin flow to the E pin, and the E pin flows to the balance resistor array. At the same time, the MCU needs to change the high level of the 4B and 6B pins of the U2 Darlington tube array to a low level through two PWM signals, and the corresponding 4C pins and 6C pins are respectively turned on, and the balanced current is controlled by E The pins flow in and return to the negative terminals of batteries B3 and B5, respectively.

[0033] Two strings of non-adjacent battery strings are balanced, and the single-chip microcomputer sends two PWM signals with the same frequency and opposite phases, respectively controlling the Darlington tubes corresponding to the total positive and negat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com