Electromagnetic-piezoelectric hybrid double-effect quasi-zero stiffness vibration energy harvesting device

A quasi-zero stiffness, piezoelectric energy capture technology, used in electromechanical devices, generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

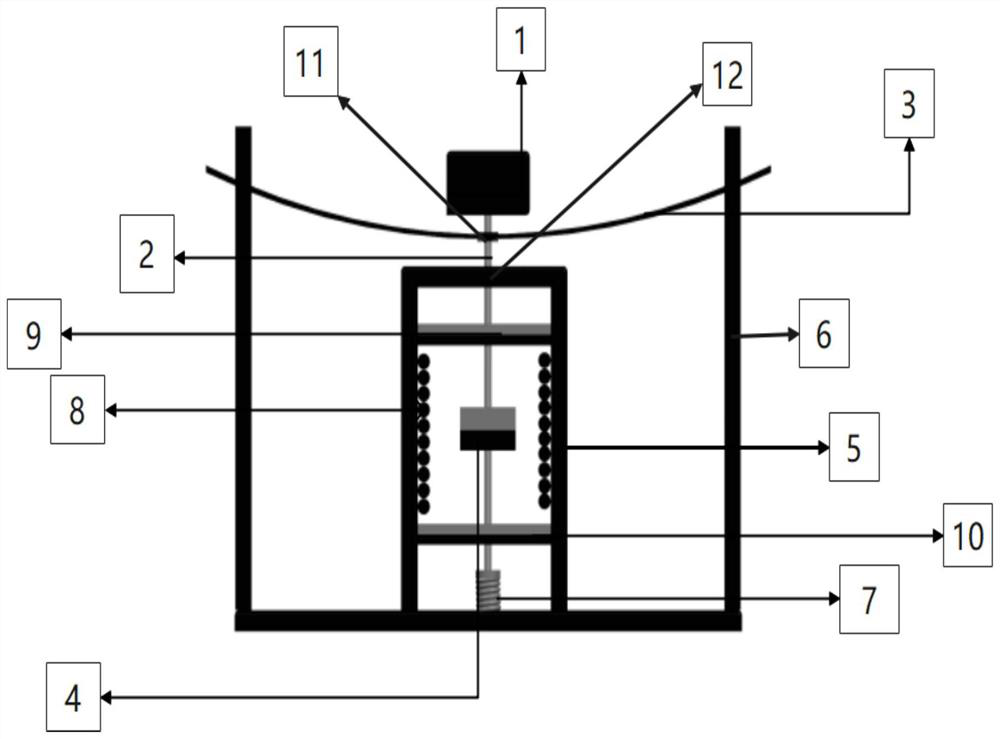

Image

Examples

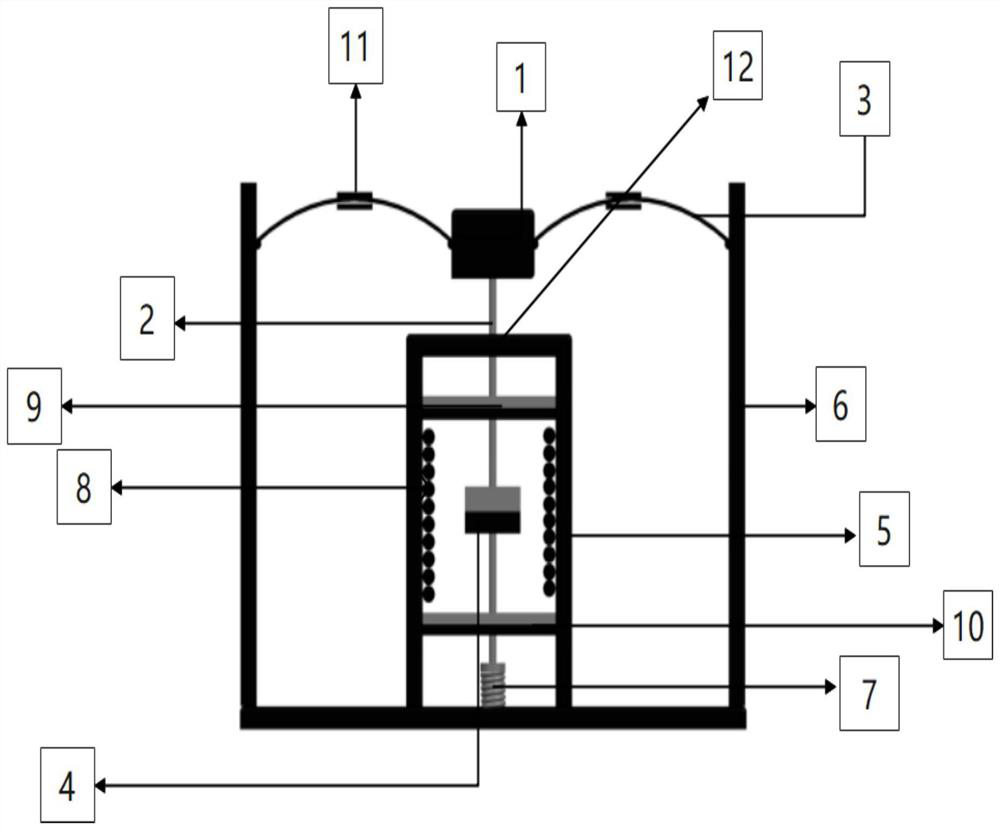

Embodiment 2

[0048] structured as figure 2 As shown, the difference from Embodiment 1 is that the Euler crank arm 3 assembly includes two negative stiffness crank arms 3, and the two negative stiffness crank arms 3 are symmetrically arranged on both sides of the mass block 1, and each crank arm One end of 3 is fixedly connected with the mass block 1, and the other end is fixedly connected with the side wall of the first rigid frame 6, and a piezoelectric energy harvesting element 11 is installed on each crank arm 3.

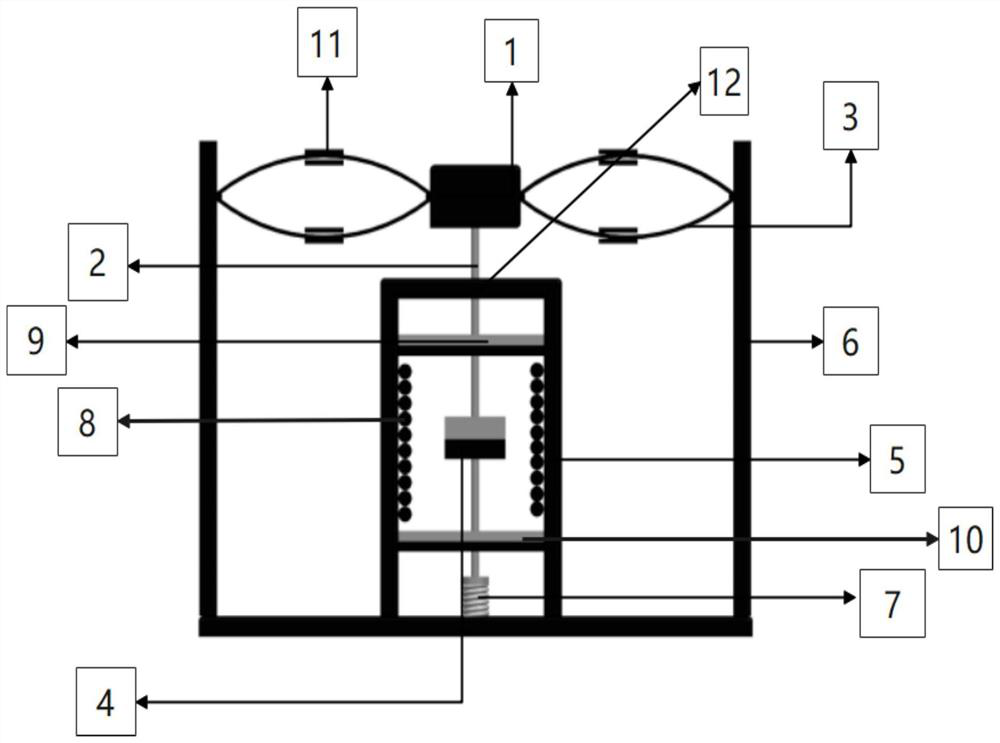

Embodiment 3

[0050] structured as image 3 As shown, the difference from Embodiment 1 is that: the Euler crank arm 3 assembly includes four negative stiffness crank arms 3, and the four negative stiffness crank arms 3 are symmetrically arranged on both sides of the mass block 1 in pairs, each One end of the crank arm 3 is fixedly connected with the mass block 1, and the other end is fixedly connected with the side wall of the first rigid frame 6, and the two crank arms 3 in each group are arranged opposite to each other, and each crank arm 3 is equipped with a piezoelectric Energy capture element 11.

[0051] To sum up, the present invention is a feasible structure based on electromagnetic and piezoelectric energy conversion mechanisms of compound vibration energy harvesting and quasi-zero stiffness vibration isolation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com