Sealing protection rubber coating material and preparation method thereof

A rubber coating and coating technology, applied in rubber derivative coatings, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of lower coating production efficiency, slow mixing between raw materials, and short sealing protection period, so as to improve sealing Protective effect and adhesion, improve coating anti-corrosion performance, optimize the effect of powder addition process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

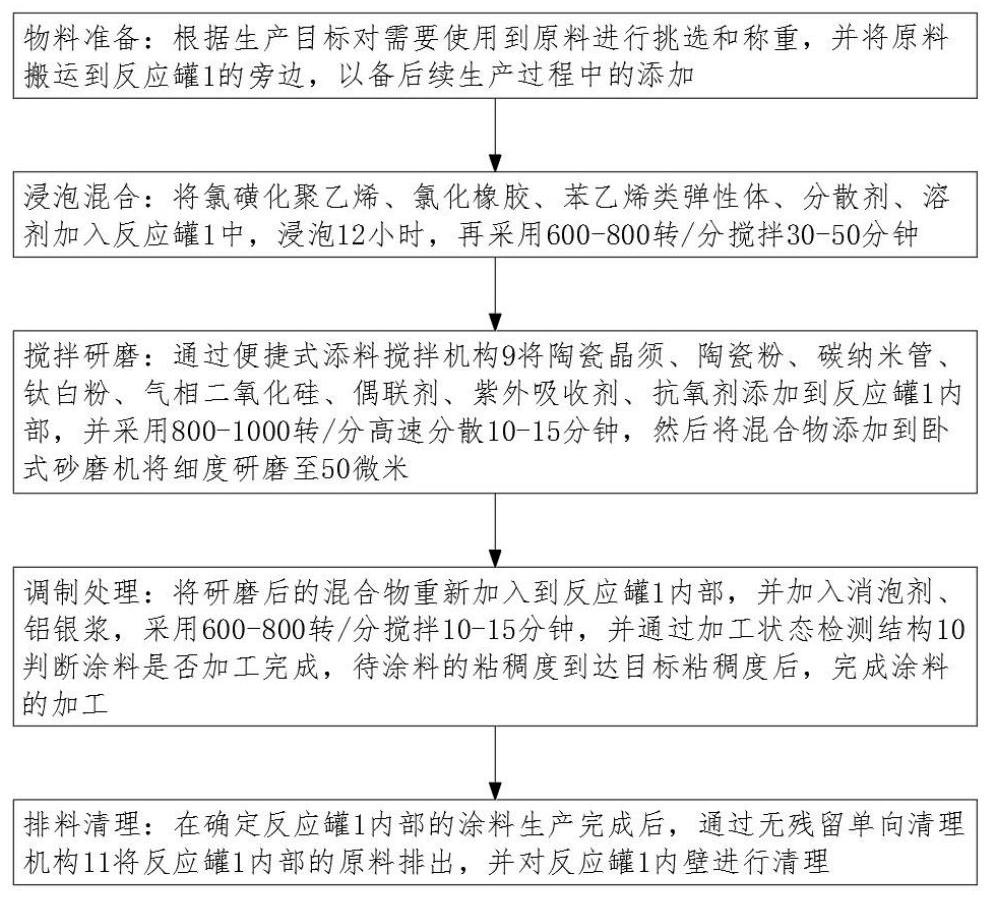

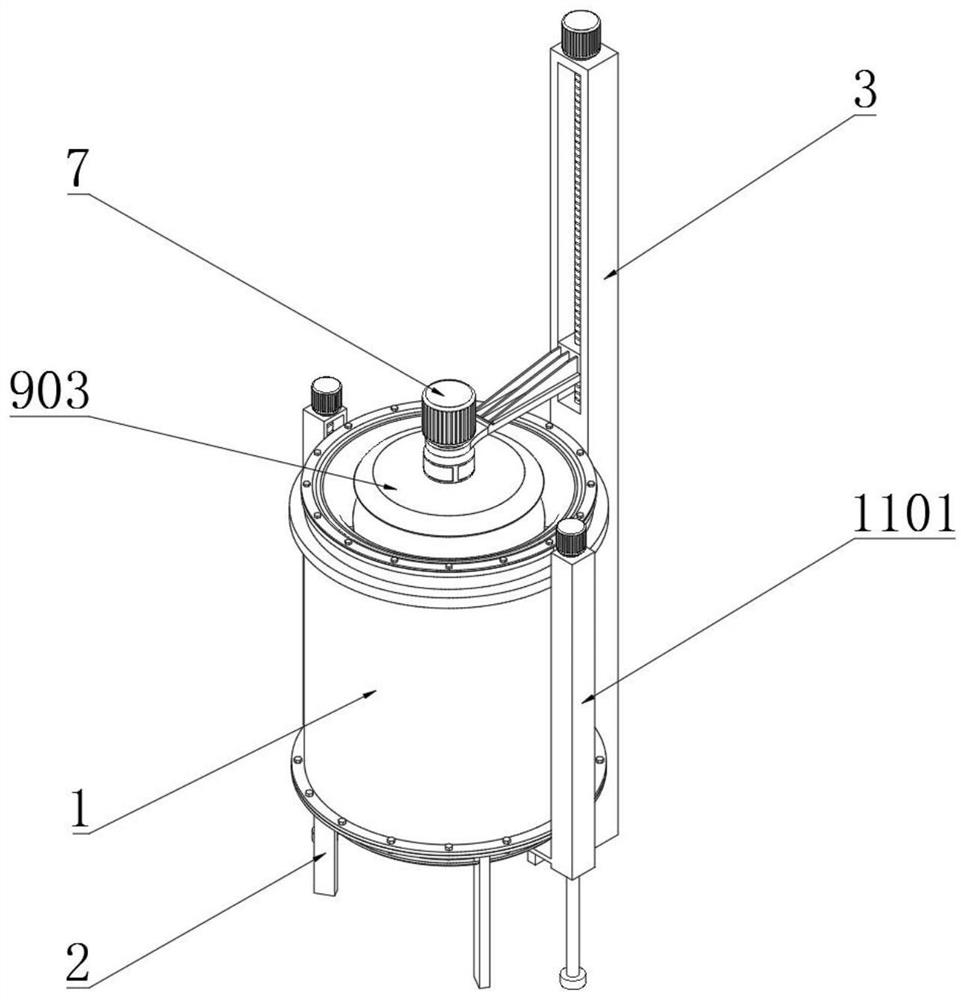

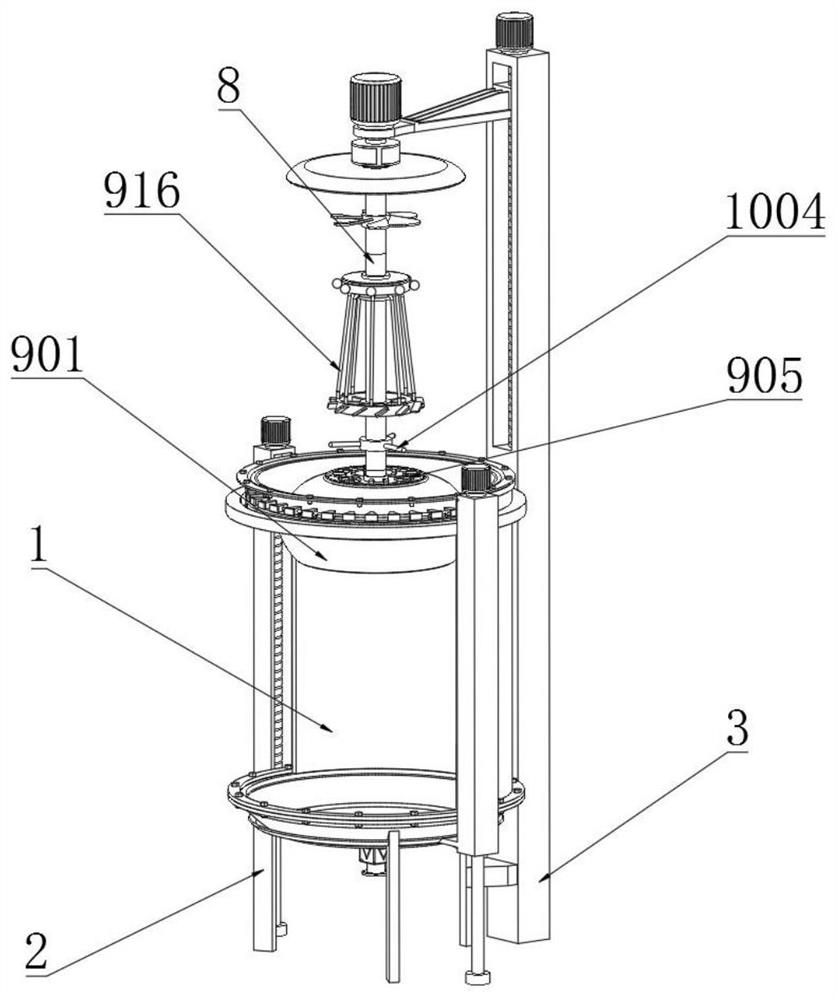

[0041] Such as Figure 1-2 As shown, the present invention provides a kind of technical scheme, a kind of preparation method of sealing protective rubber coating, comprises the steps:

[0042] S1. Material preparation: select and weigh the required raw materials according to the production target, and transport the raw materials to the side of the reaction tank 1 for addition in the subsequent production process;

[0043] S2. Soaking and mixing: add chlorosulfonated polyethylene, chlorinated rubber, styrene-based elastomer, dispersant, and solvent into reaction tank 1, soak for 12 hours, and then stir at 600 rpm for 30 minutes;

[0044] S3. Stirring and grinding: ceramic whiskers, ceramic powder, carbon nanotubes, titanium dioxide, fumed silica, coupling agents, ultraviolet absorbers, and antioxidants are added to the interior of the reaction tank 1 through the convenient feeding and stirring mechanism 9 , and disperse at a high speed of 800 rpm for 10 minutes, then add the m...

Embodiment 2

[0077] Such as Figure 1-2 As shown, the present invention provides a kind of technical scheme, a kind of preparation method of sealing protective rubber coating, comprises the steps:

[0078] S1. Material preparation: select and weigh the required raw materials according to the production target, and transport the raw materials to the side of the reaction tank 1 for addition in the subsequent production process;

[0079] S2. Soaking and mixing: add chlorosulfonated polyethylene, chlorinated rubber, styrene-based elastomer, dispersant, and solvent into reaction tank 1, soak for 12 hours, and then stir for 40 minutes at 700 rpm;

[0080] S3. Stirring and grinding: ceramic whiskers, ceramic powder, carbon nanotubes, titanium dioxide, fumed silica, coupling agents, ultraviolet absorbers, and antioxidants are added to the interior of the reaction tank 1 through the convenient feeding and stirring mechanism 9 , and adopt 900 rpm high-speed dispersion for 13 minutes, then add the m...

Embodiment 3

[0090] Such as Figure 1-2 As shown, the present invention provides a kind of technical scheme, a kind of preparation method of sealing protective rubber coating, comprises the steps:

[0091] S1. Material preparation: select and weigh the required raw materials according to the production target, and transport the raw materials to the side of the reaction tank 1 for addition in the subsequent production process;

[0092] S2. Soaking and mixing: add chlorosulfonated polyethylene, chlorinated rubber, styrene-based elastomer, dispersant, and solvent into reaction tank 1, soak for 12 hours, and then stir for 50 minutes at 800 rpm;

[0093] S3. Stirring and grinding: ceramic whiskers, ceramic powder, carbon nanotubes, titanium dioxide, fumed silica, coupling agents, ultraviolet absorbers, and antioxidants are added to the interior of the reaction tank 1 through the convenient feeding and stirring mechanism 9 , and use 1000 rpm high-speed dispersion for 15 minutes, then add the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com