Anti-rust wax for automobile chassis and preparation method thereof

A technology for automobile chassis and anti-rust wax, applied in wax coatings, anti-corrosion coatings, coatings, etc., can solve the problems of humidity and temperature effects, and high flammable VOC emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

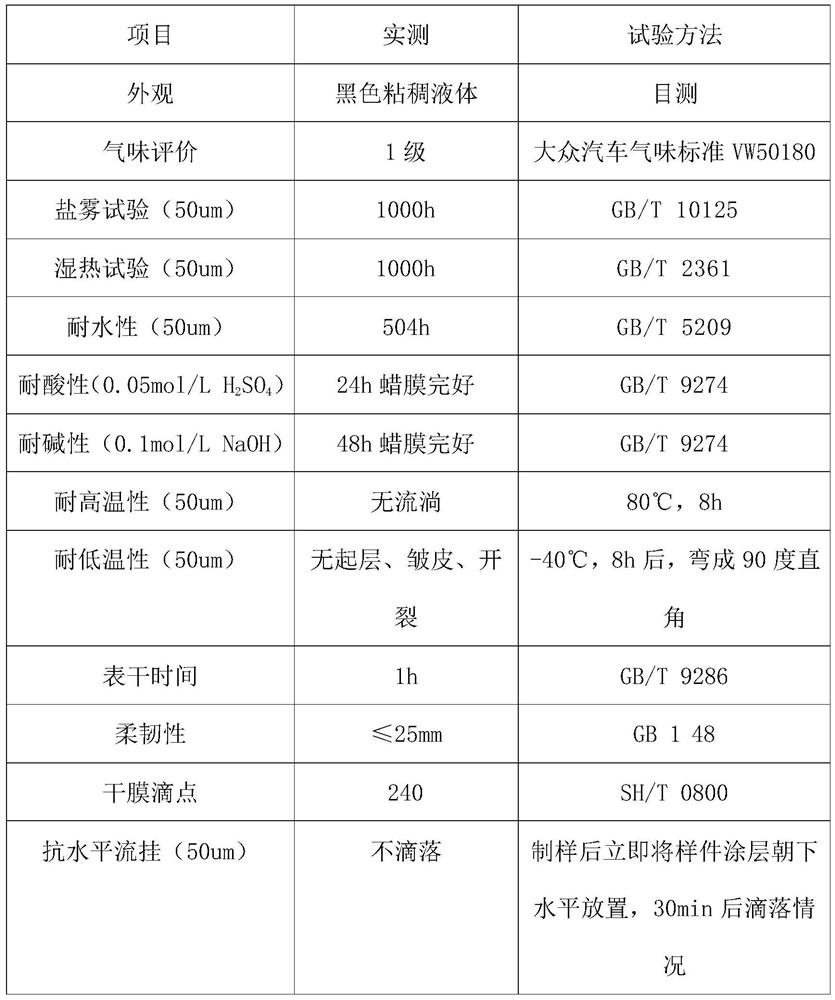

Image

Examples

Embodiment 1

[0020] Step 1: Add raw material wax and base oil to the reaction vessel, heat to 110°C, and stir evenly;

[0021] Step 2: Continue to add the modified resin to the reaction vessel to dissolve it completely. After stirring for 30 minutes, add the modified vegetable oil. When the temperature drops to 60°C, add the thixotropic agent, stir for 10 minutes, add the drier and oily dye, and continue After stirring for 10 minutes, the automobile chassis antirust wax is prepared.

[0022] In the present embodiment: the mass fraction of each component in the antirust wax is: 30% of modified vegetable oil, 15% of raw wax, 32% of base oil, 10.1% of modified resin, 10% of thixotropic agent, 0.4% of drier, Dyeing agent 1.5%;

[0023] Modified vegetable oil: polymerized linseed oil 10%, polymerized soybean oil 20%

[0024] Raw material wax: 90# microcrystalline wax 15%

[0025] Base oil: 60N base oil 5%, 150SN base oil 27%

[0026] Modified resin: polyamide modified phenolic resin 2%, asp...

Embodiment 2

[0031] Step 1: Add raw material wax and base oil to the reaction vessel, heat to 105°C, and stir evenly;

[0032] Step 2: Continue to add the modified resin to the reaction vessel to dissolve it completely. After stirring for 30 minutes, add the modified vegetable oil. When the temperature drops to 60°C, add the thixotropic agent, stir for 10 minutes, add the drier and oily dye, and continue After stirring for 10 minutes, the automobile chassis antirust wax is prepared.

[0033] In the present embodiment: the mass fraction of each component in the antirust wax is: 36% of modified vegetable oil, 12% of raw wax, 26% of base oil, 12% of modified resin, 11.6% of thixotropic agent, 0.4% of drier, Oily stain 2%;

[0034] Modified vegetable oil: dehydrated castor oil 12.5%, tung oil 23.5%

[0035] Raw material wax: paraffin wax 7%, polyethylene wax 5%

[0036] Base oil: 10# mechanical oil 15%, industrial white oil 11%

[0037] Modified resin: Rosin modified phenolic resin 4%, asp...

Embodiment 3

[0042] Step 1: Add raw material wax and base oil to the reaction vessel, heat to 110°C, and stir evenly;

[0043] Step 2: Continue to add the modified resin to the reaction vessel to dissolve it completely. After stirring for 30 minutes, add the modified vegetable oil. When the temperature drops to 60°C, add the thixotropic agent, stir for 10 minutes, add the drier and oily dye, and continue After stirring for 10 minutes, the automobile chassis antirust wax is prepared.

[0044] In this embodiment: the mass fractions of each component in the antirust wax are: 40% of modified vegetable oil, 10% of raw wax, 20% of base oil, 12.8% of modified resin, 15% of thixotropic agent, 0.2% of drier, Oily stain 2%;

[0045] Modified vegetable oil: 28% polymerized linseed oil, 12% polymerized tung oil

[0046] Raw material wax: paraffin wax 3%, 90# microcrystalline wax 7%

[0047] Base oil: 60N base oil 10%, 32# machine oil 10%

[0048] Modified resin: polyamide modified phenolic resin 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com