Cleaning solution for semiconductor integrated circuit and production process of cleaning solution

A technology for integrated circuits and semiconductors, which is applied in the field of cleaning liquid for semiconductor integrated circuits and its production process, and can solve problems such as performance impact and failure to meet use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Prepare modifying agent, this modifying agent is made by following steps:

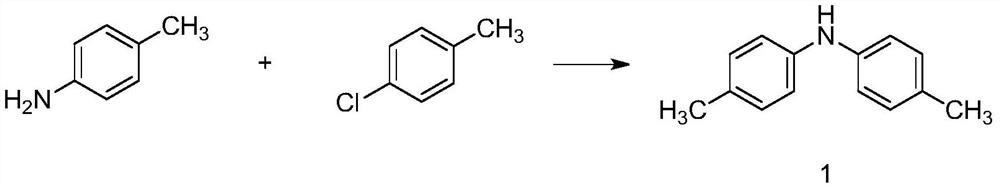

[0039] Step S1: Add p-aminotoluene, p-chlorotoluene and toluene into the flask, pass through nitrogen protection, add palladium acetate, binaphthyl diphenylphosphine and cesium carbonate, stir and react at a temperature of 75°C for 5 hours, after the reaction, Intermediate 1 was obtained;

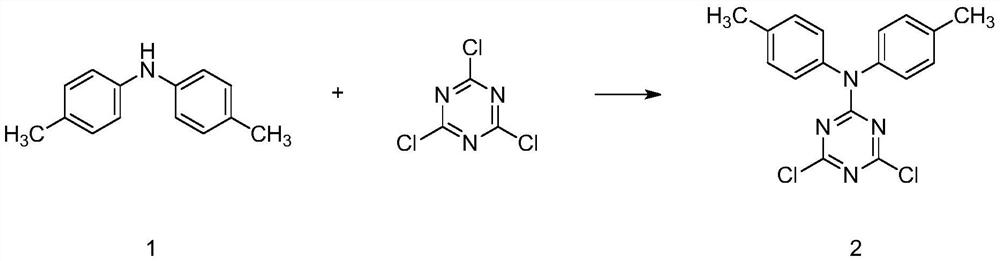

[0040] Step S2: Add cyanuric chloride, N,N-diisopropylethylamine, and tetrahydrofuran into the flask, pass through nitrogen protection, stir for 10 minutes at a temperature of 0°C and a rotation speed of 300r / min, and then add the intermediate Body 1 was reacted for 3h to obtain Intermediate 2;

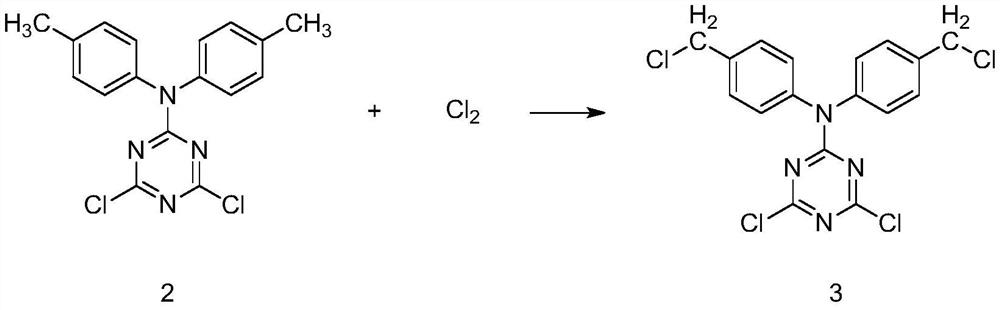

[0041] Step S3: Add intermediate 2 and tetrahydrofuran into the flask, stir for 10 min at a temperature of 20°C and a rotational speed of 200 r / min, then pass in chlorine gas, and react for 1 h under light conditions to obtain intermediate 3;

[0042] Step S4: Add intermediate 3, potassium carbonate, and deionized ...

Embodiment 2

[0046] Prepare modifying agent, this modifying agent is made by following steps:

[0047] Step S1: Add p-aminotoluene, p-chlorotoluene and toluene into the flask, pass through nitrogen protection, add palladium acetate, binaphthyl diphenylphosphine and cesium carbonate, stir and react at a temperature of 75°C for 5 hours, after the reaction, Intermediate 1 was obtained;

[0048] Step S2: Add cyanuric chloride, N,N-diisopropylethylamine, and tetrahydrofuran into the flask, pass through nitrogen protection, stir for 15 minutes at a temperature of 3°C and a rotation speed of 300r / min, and then add the intermediate Body 1 was reacted for 4h to obtain Intermediate 2;

[0049] Step S3: Add intermediate 2 and tetrahydrofuran into the flask, stir for 15 minutes at a temperature of 25° C. and a rotation speed of 300 r / min, then pass in chlorine gas, and react for 1.25 hours under light conditions to obtain intermediate 3;

[0050] Step S4: Add intermediate 3, potassium carbonate, and d...

Embodiment 3

[0054] Prepare modifying agent, this modifying agent is made by following steps:

[0055] Step S1: Add p-aminotoluene, p-chlorotoluene and toluene into the flask, pass through nitrogen protection, add palladium acetate, binaphthyl diphenylphosphine and cesium carbonate, stir and react at a temperature of 75°C for 5 hours, after the reaction, Intermediate 1 was obtained;

[0056] Step S2: Add cyanuric chloride, N,N-diisopropylethylamine, and tetrahydrofuran into the flask, pass through nitrogen protection, stir for 20 minutes at a temperature of 5°C and a rotation speed of 300r / min, and then add the intermediate Body 1 was reacted for 5h to obtain Intermediate 2;

[0057] Step S3: Add intermediate 2 and tetrahydrofuran into the flask, stir for 20 minutes at a temperature of 30° C. and a rotation speed of 400 r / min, then pass in chlorine gas, and react for 1.5 hours under light conditions to obtain intermediate 3;

[0058] Step S4: Add intermediate 3, potassium carbonate, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com