a ni-doped ti 3 sic 2 /cu composite material and its preparation method and application

A composite material and powder technology, which is applied in the field of copper-based composite material preparation, can solve problems such as increased turning resistance of turnouts, increased switching resistance, and poor switching of turnouts, and achieves the effects of increasing service life, improving service performance, and improving material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A kind of Ni-doped Ti of the present invention 3 SiC 2 / Cu composite material and preparation method thereof, comprising the following steps:

[0042] S1, the Ti 3 SiC 2 Powder, Ni powder and Cu powder are mixed according to a certain composition ratio, and poured into a ball mill tank for ball milling;

[0043] Ti 3 SiC 2 The composition ratio of powder, Ni powder and Cu powder is: Ti 3 SiC 2 The powder composition is 10Vol.%-30Vol.%, the Ni powder composition is 8Vol.%-10Vol.%, and the Cu powder composition is 60Vol.%-82Vol.%.

[0044] Ti 3 SiC 2 The particle size of the powder is 200-325 mesh, the purity is 97.5%-99.0%, and the shape structure is irregular; the particle size of the Ni powder is 100-200 mesh, the purity is 98.5%-99.9%, water atomized spherical powder; Cu powder The particle size is 100-200 mesh, the purity is 98.5%-99.9%, and it is water-atomized spherical powder.

[0045] The ball milling parameters are that the ball milling time is 3-4 ho...

Embodiment 1

[0053] Maglev Turnout Sliding Bed Platform

[0054] 1) 30Vol.% Ti 3 SiC 2 powder, 10Vol.% Ni powder and 60Vol.% Cu powder were mixed and poured into a ball mill jar for ball milling.

[0055] Ti 3 SiC 2 The particle size of the powder is 325 mesh, the purity is 99.0%, and the shape structure is irregular; the particle size of the Ni powder is 200 mesh, the purity is 99.9%, and the water atomized spherical powder; the particle size of the Cu powder is 200 mesh, the purity is 99.9%. Water atomized spherical powder. The ball milling parameters are that the ball milling time is 4 hours, and the ball milling speed is 250 rpm.

[0056] 2) Put the ball-milled and uniformly dispersed powder into a specific mold, perform cold pressing and pressureless sintering, and then obtain Ni-doped Ti that can be used for the turnout slide bed platen 3 SiC 2 / Cu composite material.

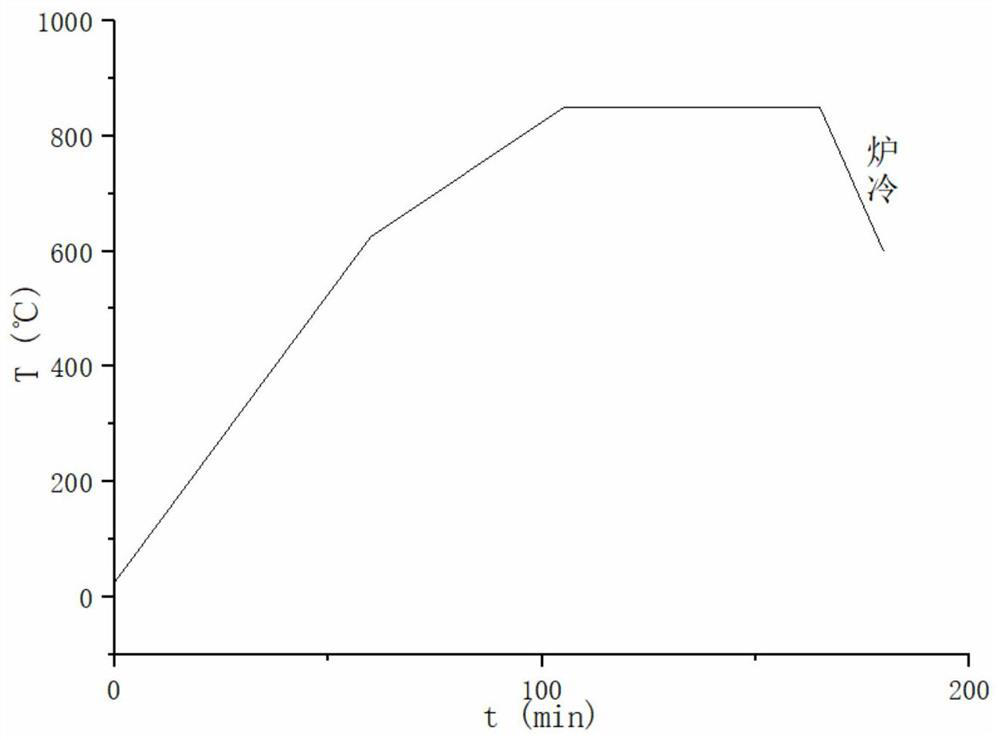

[0057] A cuboid mold with a size of 20mm×200mm×5mm is used. The cold pressing parameter is a load of 800MP...

Embodiment 2

[0059] Plateau railway turnout sliding bed platform

[0060] 1) 20Vol.% Ti 3 SiC 2 powder, 9Vol.% Ni powder and 71Vol.% Cu powder were mixed and poured into a ball mill jar for ball milling.

[0061] Ti 3 SiC 2 The particle size of the powder is 250 mesh, the purity is 98.0%, and the shape structure is irregular; the particle size of the Ni powder is 150 mesh, the purity is 99.0%, and the water atomized spherical powder; the particle size of the Cu powder is 150 mesh, the purity is 99.0%. Water atomized spherical powder. The ball milling parameters are that the ball milling time is 4 hours, and the ball milling speed is 200 rpm.

[0062] 2) Put the ball-milled and uniformly dispersed powder into a specific mold, perform cold pressing and pressureless sintering, and then obtain Ni-doped Ti that can be used for the turnout slide bed platen 3 SiC 2 / Cu composite material.

[0063]Among them, a cuboid mold with a size of 70mm×70mm×8mm is used. The cold pressing parameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com