Nickel-based alloy additive manufacturing method

A technology of additive manufacturing and nickel-based alloys, which is applied in the direction of additive processing, metal material coating technology, coating, etc., can solve the problems of increasing production costs and increasing production processes, so as to reduce the deformation of workpieces and improve performance , The effect of refining the structure and grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

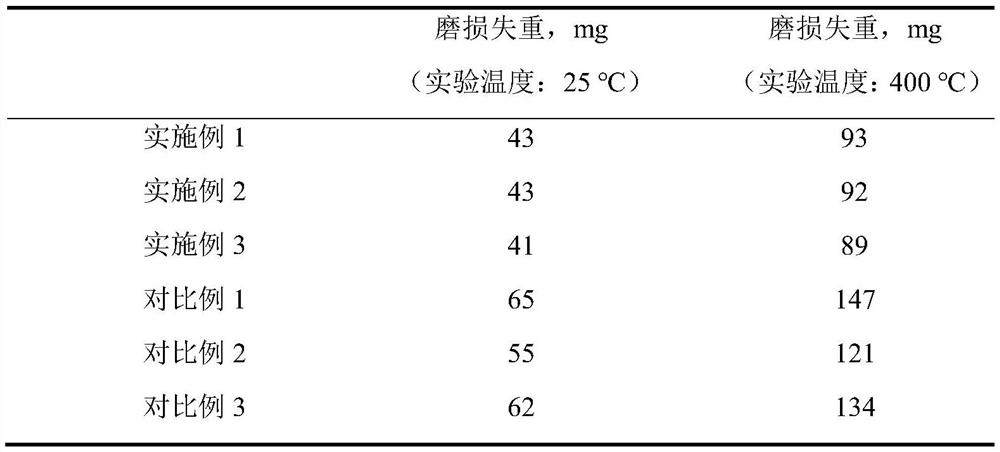

Embodiment 1

[0018] Nickel-based alloy selects a commercially available Inconel 718 alloy. Additive manufacturing according to the following steps:

[0019] Step (1): Preparation of the molten powder. The chemical composition of the nickel-based powder is calculated by mass, Ti is 1.7%, CR is 1.5%, Si is 1.0%, and the composite rare earth is 0.6%, C is 0.2%, B is 0.2%, V is 0.08. %, SR is 0.01%, the margin is Ni, and the powder particle size is 100 ~ 240 mesh. Among them, the chemical composition of composite rare earths is 30%, EU is 30%, ND is 5%, PM is 5%, PR is 1%, and Gd is 1%, and the remaining CE. Before the laser cladding process, the powder is required to be ground and mixed in a vacuum ball mill, and the time is 3 to 5 min, ensuring uniform powder mixing and the powder shape is a spherical or near spherical; then a vacuum incubator in a temperature of 50 to 60 ° C. Insulation is 6 to 8 minutes to remove moisture.

[0020] Step (2): Laser cladding process. With fiber lasers, laser mol...

Embodiment 2

[0023] Nickel-based alloy selects a commercially available Inconel 718 alloy. Additive manufacturing according to the following steps:

[0024] Step (1): Preparation of the molten powder. The chemical composition of the nickel-based powder was calculated by mass, Ti was 1.9%, CR was 1.7%, Si was 1.2%, and the composite rare earth was 1.0%, C was 0.4%, B was 0.4%, V is 0.12. %, SR is 0.03%, the margin is Ni, and the powder particle size is 100 ~ 240 mesh. Among them, the chemical composition of composite rare earths is 36%, Eu is 36%, ND of 7%, PM is 7%, PR is 3%, Gd is 3%, and the remaining CE. Before the laser cladding process, the powder is required to be ground and mixed in a vacuum ball mill, and the time is 3 to 5 min, ensuring uniform powder mixing and the powder shape is a spherical or near spherical; then a vacuum incubator in a temperature of 50 to 60 ° C. Insulation is 6 to 8 minutes to remove moisture.

[0025] Step (2): Laser cladding process. With fiber lasers, laser ...

Embodiment 3

[0028] Nickel-based alloy selects a commercially available Inconel 718 alloy. Additive manufacturing according to the following steps:

[0029] Step (1): Preparation of the molten powder. The chemical composition of the nickel-based powder was calculated by mass, and Ti was 40%, CR was 1.6%, and Cu was 1.6%, Si was 1.1%, and the composite rare earth was 0.8%, C was 0.3%, B was 0.3%, V is 0.1. %, SR is 0.02%, the margin is Ni, and the powder particle size is 100 ~ 240 mesh. Among them, the chemical composition of composite rare earths is: La is 33%, Eu is 33%, ND is 6%, PM is 6%, PR is 2%, Gd is 2%, and the remaining CE. Before the laser cladding process, the powder is required to be ground and mixed in a vacuum ball mill, and the time is 3 to 5 min, ensuring uniform powder mixing and the powder shape is a spherical or near spherical; then a vacuum incubator in a temperature of 50 to 60 ° C. Insulation is 6 to 8 minutes to remove moisture.

[0030] Step (2): Laser cladding process....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com