All-rotation all-casing drilling machine construction method suitable for karst cave geology

A construction method and full-rotation technology, applied in drilling equipment and methods, drilling tools, drilling equipment, etc., can solve problems such as inability to carry out pile foundation construction, and achieve the effect of improving flatness and bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] This part will describe the specific embodiment of the present invention in detail, and the preferred embodiment of the present invention is shown in the accompanying drawings. Each technical feature and overall technical solution of the invention should not be construed as limiting the protection scope of the present invention.

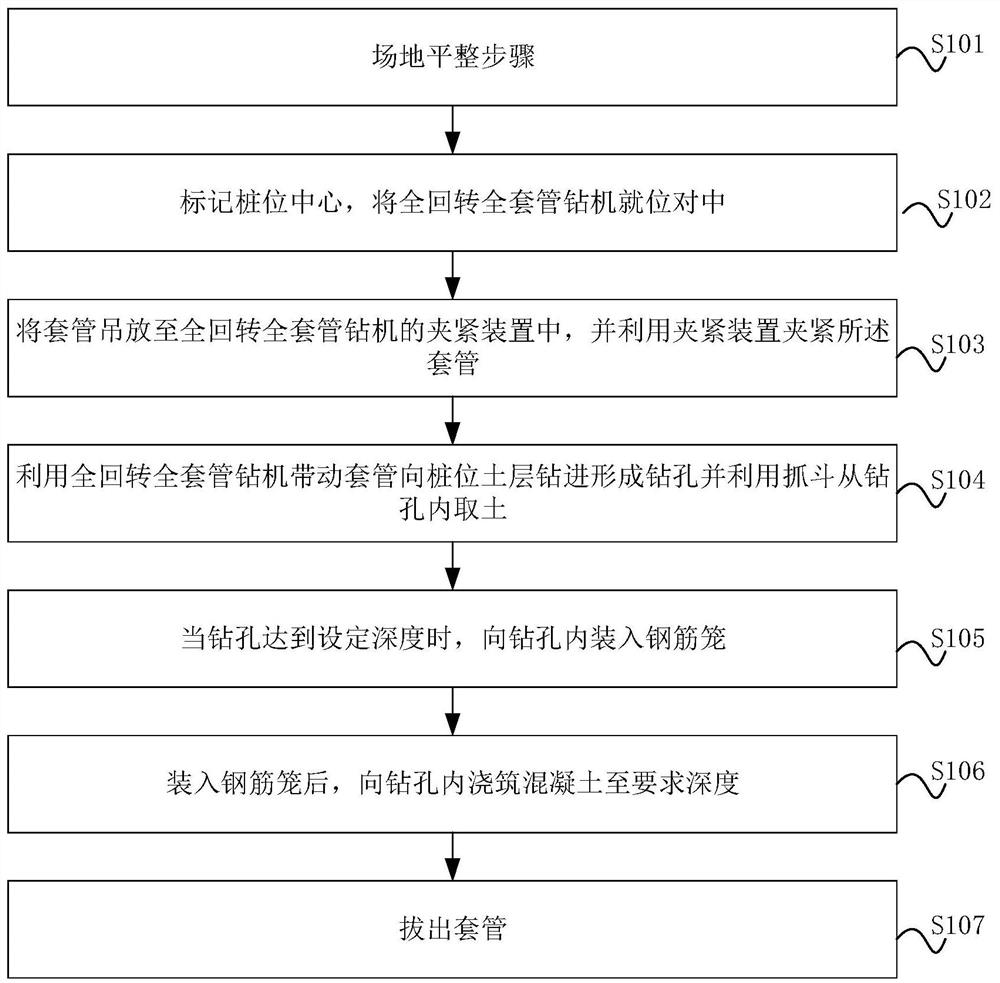

[0037] Such as figure 1 As shown, in one embodiment, a construction method of full-rotation full-casing drilling rig suitable for karst cave geology is provided, and the method includes the following steps:

[0038] Step S101: Site leveling step.

[0039] Specifically, the site leveling step specifically includes the following sub-steps:

[0040] Step S1011: pumping out the stagnant water in the site, and making a drainage ditch for the site;

[0041] Step S1012: remove the mud layer that has been soaked by water until the hard soil layer is removed;

[0042] Step S1013: Pave and fill the brick slag layer with a set thickness on the hard s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com