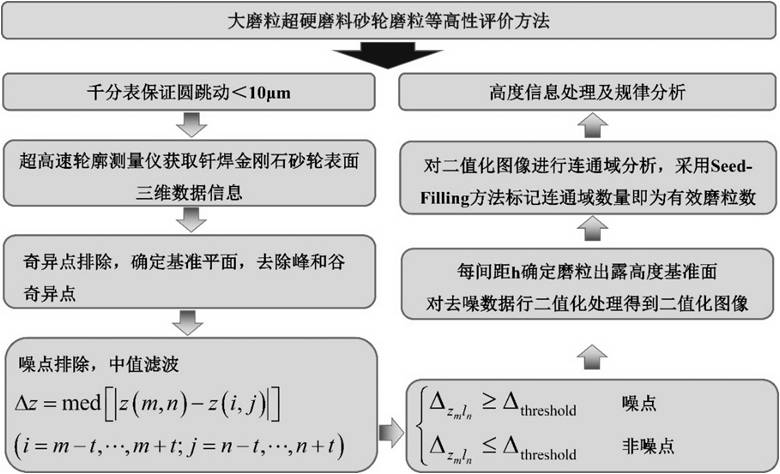

Abrasive particle contour evaluation method for large-abrasive-particle superhard abrasive grinding wheel

A super-hard abrasive and evaluation method technology, applied in image data processing, special data processing applications, instruments, etc., can solve the problems of difficulty in obtaining information on the height of abrasive grains, difficulty in evaluating the iso-height, and achieve the effect of high-efficiency evaluation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

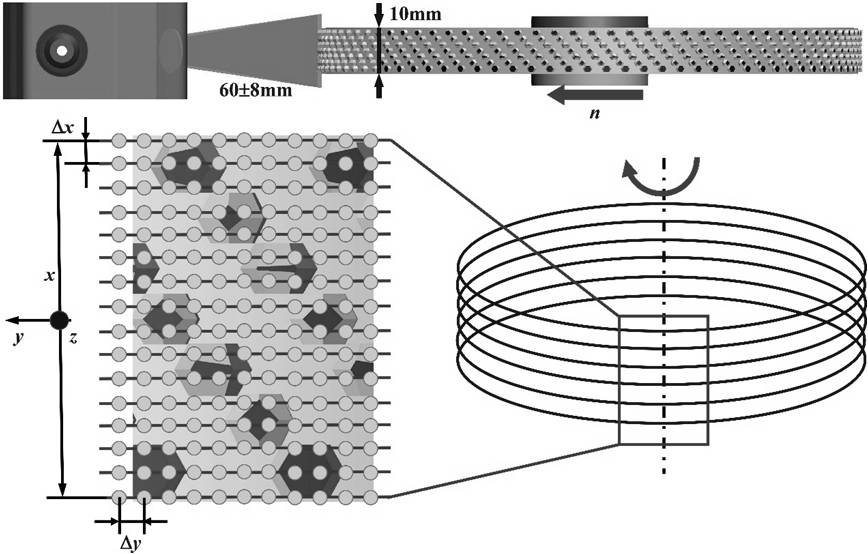

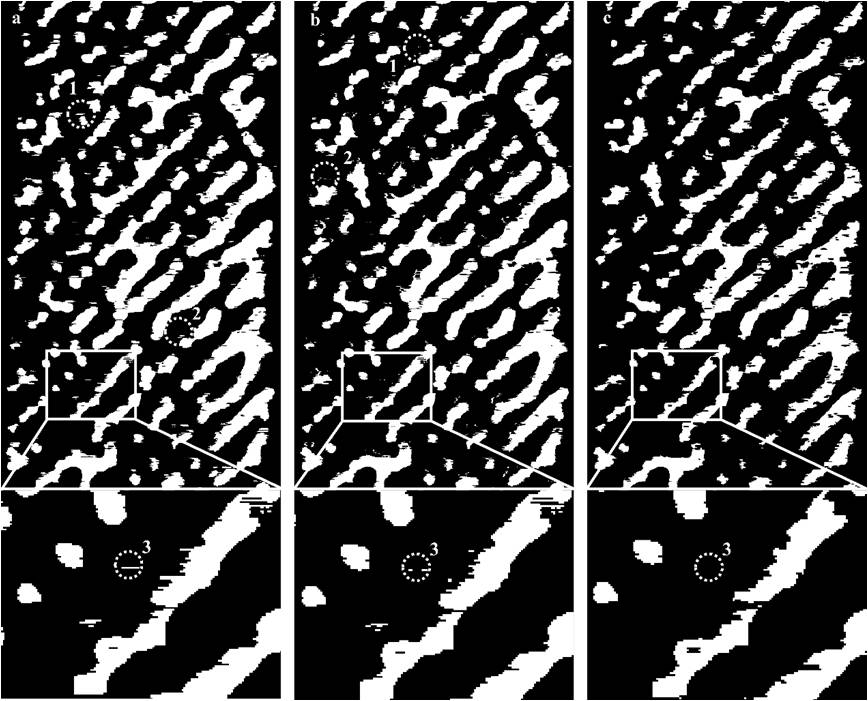

[0057] The three-dimensional data on the surface of the brazed diamond grinding wheel with orderly arrangement of abrasive grains before and after shaping was detected by an ultra-high-speed profile measuring instrument (KEYENCE, LJ-V7060, Japan). Before testing, adjust the installation fixture to ensure that the circular runout of the grinding wheel is within 10 μm (measured with a dial gauge). Among them, the measurement range of the ultra-high-speed profile measuring instrument z Shaft 60±8mm, x Shaft 15 mm, repeatability: z axis 0.4 μm, x Axis 5 μm, spot diameter: about 21 mm×45 μm, number of profile data: 800 points, blue semiconductor laser, wavelength 405 nm, output power 10 mW, spot diameter about 21 mm×45 μm, profile data interval ( x axis) 20 μm, sampling frequency 1000 Hz, grinding wheel speed 10 rad / s. Orderly arrangement of abrasive grains Brazed diamond large abrasive grain superabrasive grinding wheel Ultra-high-speed profile measuring instrument Surface thr...

Embodiment 2

[0079] The difference with embodiment 1 is: this embodiment adopts The electroplated large abrasive superabrasive grinding wheel was used as the research object, and the grinding wheel was shaped by mechanical methods such as Cr12 stainless steel and oil stone. Set the grinding wheel speed, feed speed, dressing depth, and dressing time according to the diameter of the grinding wheel and the size of the abrasive grain. Then the method of the present invention is used to evaluate the abrasiveness of the grinding wheel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com