Novel nano-composite environment-friendly material for removing formaldehyde peculiar smell and preparation method of novel nano-composite environment-friendly material

A formaldehyde odor and nano-composite technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of unsatisfactory activated carbon adsorption effects, etc., and achieve suitable for popularization and use, increase absorption effect, and good absorption efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

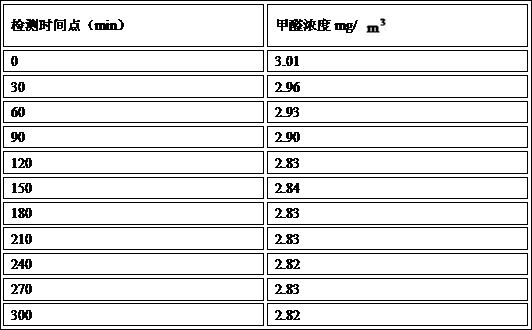

Examples

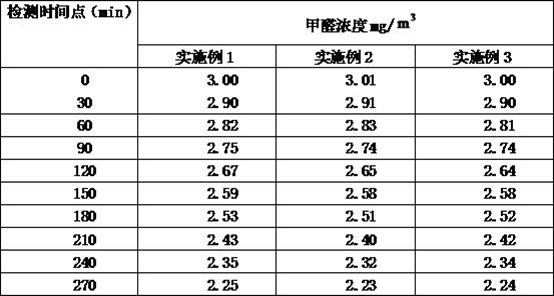

Embodiment 1

[0025] This embodiment provides a new nano-composite formaldehyde-removing odor-friendly environmental protection material, including the following raw materials in parts by weight: 5 parts of titanium dioxide, 10 parts of nano-silver, 2 parts of thickener, 4 parts of sodium percarbonate, 50 parts of deionized water, activated carbon 70 parts, 10 parts of activated alumina powder, 15 parts of amino acid mixture.

[0026] The thickener is one or more of polyurethane, starch, and hydroxymethyl cellulose, and the thickener is used to increase the viscosity of the solution; the amino acid mixture is a solution of a class of organic compounds containing amino or carboxyl groups , at room temperature, formaldehyde can react with the amino group in the amino acid mixture and generate hydroxymethyl derivatives to achieve the removal of formaldehyde.

[0027] A method for preparing a nano-composite formaldehyde-removing and environmentally friendly new material, comprising the followin...

Embodiment 2

[0037] This example provides a new nano-composite formaldehyde-removing and environmentally friendly material, including the following raw materials in parts by weight: 10 parts of titanium dioxide, 20 parts of nano-silver, 6 parts of thickener, 10 parts of sodium percarbonate, 80 parts of deionized water, activated carbon 90 parts, 20 parts of activated alumina powder, 30 parts of amino acid mixture.

[0038] The thickener is one or more of polyurethane, starch, and hydroxymethyl cellulose, and the thickener is used to increase the viscosity of the solution; the amino acid mixture is a solution of a class of organic compounds containing amino or carboxyl groups , at room temperature, formaldehyde can react with the amino group in the amino acid mixture and generate hydroxymethyl derivatives to achieve the removal of formaldehyde.

[0039] A method for preparing a nano-composite formaldehyde-removing and environmentally friendly new material, comprising the following steps:

...

Embodiment 3

[0049] This embodiment provides a new nano-composite formaldehyde-removing and environmentally friendly material, including the following raw materials in parts by weight: 7 parts of titanium dioxide, 15 parts of nano-silver, 4 parts of thickener, 7 parts of sodium percarbonate, 65 parts of deionized water, 80 parts of activated carbon, 15 parts of activated alumina powder, and 22 parts of amino acid mixture.

[0050] The thickener is one or more of polyurethane, starch, and hydroxymethyl cellulose, and the thickener is used to increase the viscosity of the solution; the amino acid mixture is a solution of a class of organic compounds containing amino or carboxyl groups , at room temperature, formaldehyde can react with the amino group in the amino acid mixture and generate hydroxymethyl derivatives to achieve the removal of formaldehyde.

[0051] A method for preparing a nano-composite formaldehyde-removing and environmentally friendly new material, comprising the following s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com