Aluminum bar shaping and throttling equipment for valve body of liquefied petroleum gas pressure regulator

A technology of liquefied petroleum gas and pressure regulator, applied in other directions of manufacturing equipment/tools, metal processing, manufacturing tools, etc., can solve the problems of waste of resources, unfavorable sustainable development, bending deformation of aluminum rods, etc., to avoid waste of resources, Effects that are conducive to sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

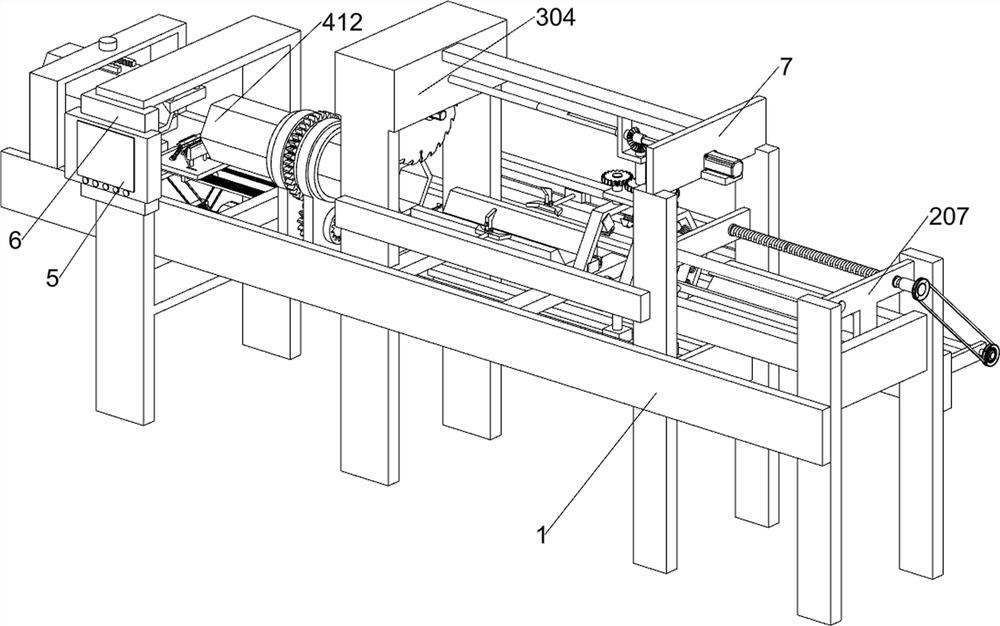

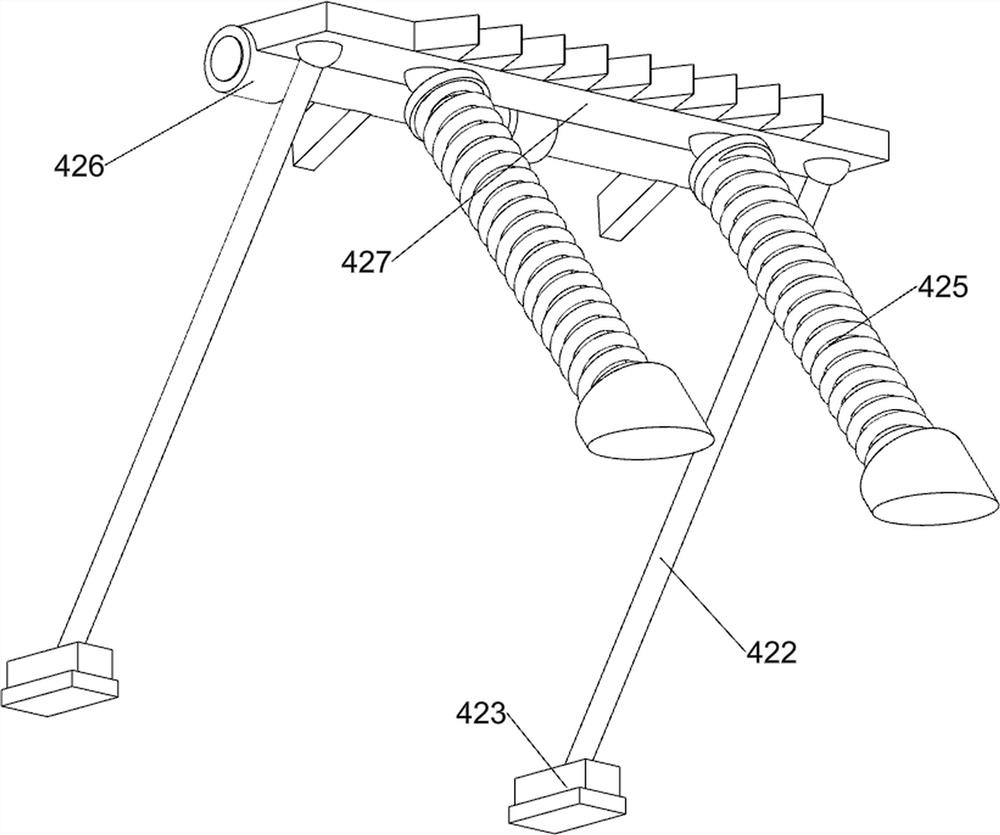

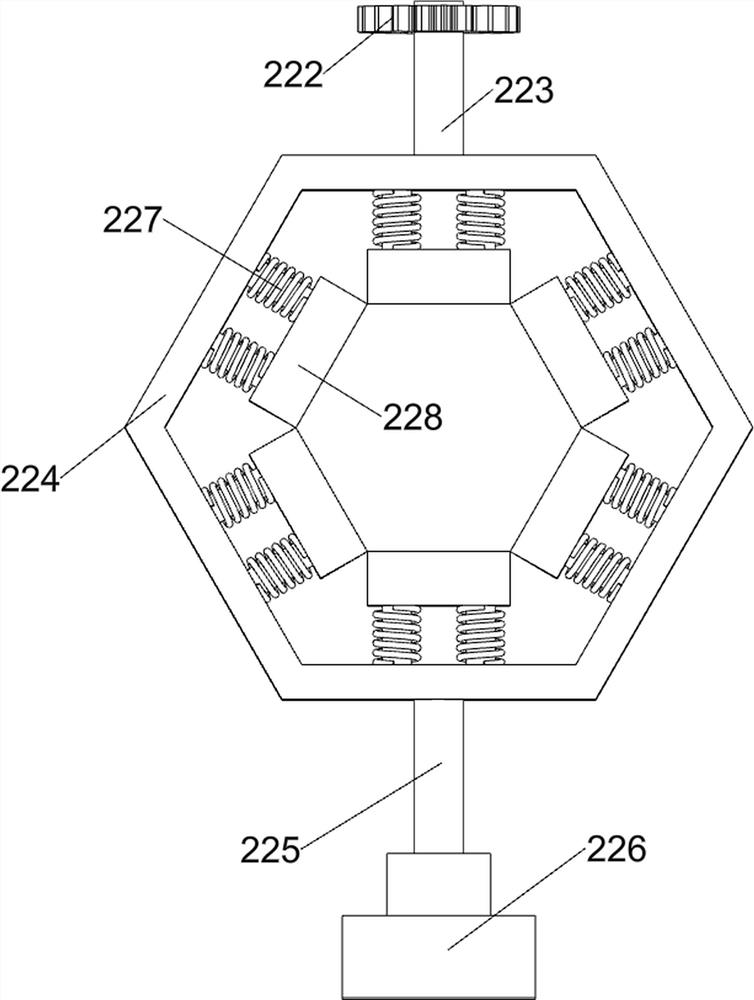

[0034] An aluminum rod conformal and throttling device for the valve body of a liquefied petroleum gas pressure regulator, according to Figure 1-2 As shown, it includes a bottom plate assembly 1, a cleaning conformal unit, a cutting unit, a scraping unit, a control panel 5, a support 6, a support plate 7, a deflector 8, a material cylinder 9, an opening and closing plate 10 and a first fixing plate 11. The bottom plate assembly 1 is fixed to the cleaning positive unit; the bottom plate assembly 1 is fixed to the cutting unit; the bottom plate assembly 1 is fixed to the scraping unit; the bottom plate assembly 1 is fixed to the support 6; the bottom plate assembly 1 is connected to the The support plate 7 is fixed; the bottom plate assembly 1 is fixed with the deflector 8; the bottom plate assembly 1 is fixed with the first fixed plate 11; the cleaning conformal unit is connected with the cutting unit in rotation; The unit is fixed; the cleaning positive unit is fixed with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com