Preparation method of antibacterial nanofiber membrane

A technology of nanofiber membrane and electrospun membrane, which is applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems that the safety, stability and antibacterial performance of antibacterial nanofiber membranes cannot meet the requirements, and achieve excellent safety, The effect of low cost and simple and easy-to-operate preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

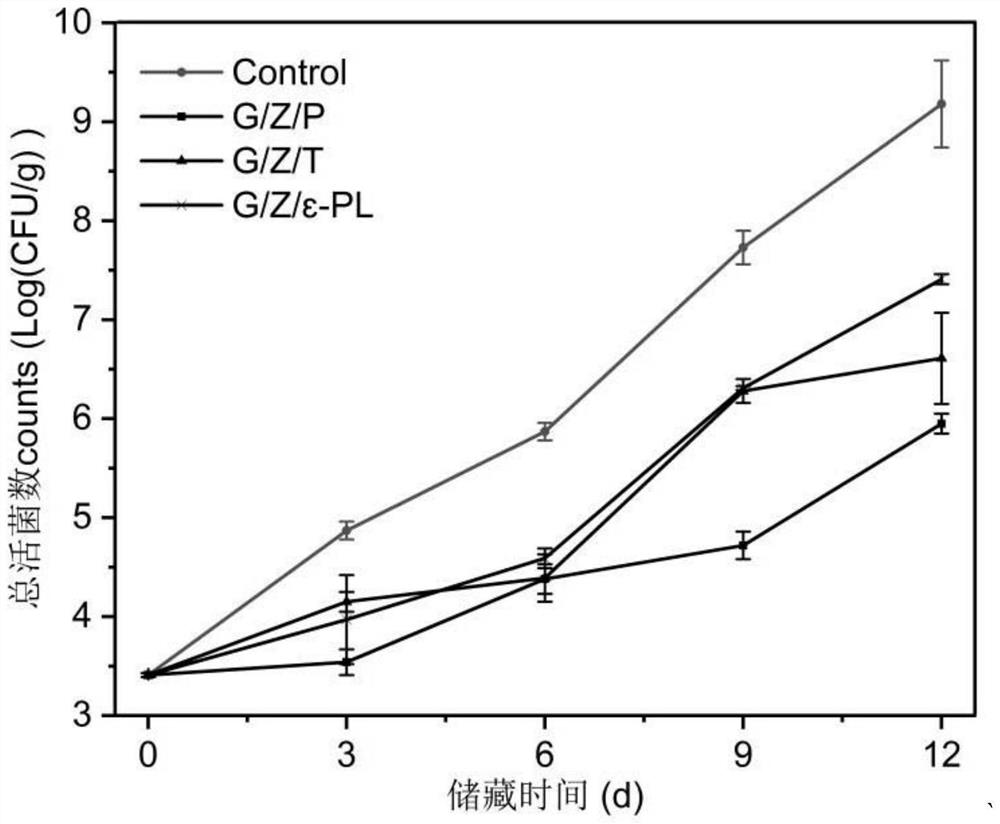

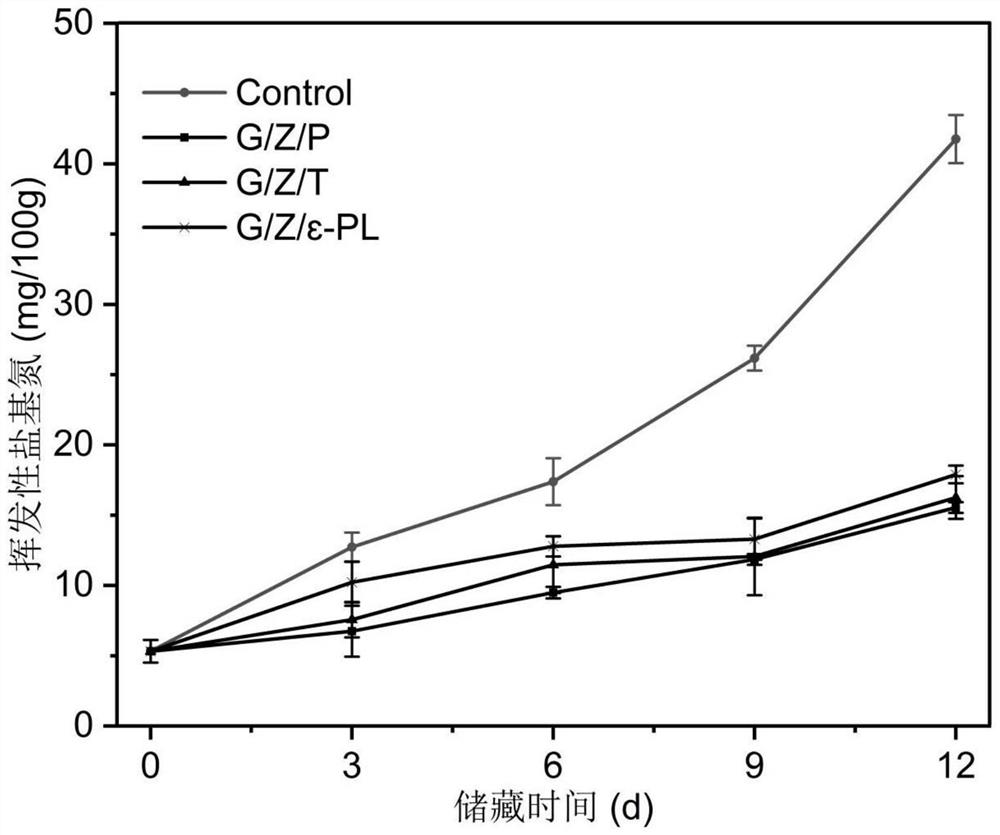

[0024] The comparison of embodiment 1 antibacterial agent

[0025] Dissolve 12.5g of gelatin in 100mL of acetic acid solution (80% v / v distilled water), stir on a magnetic stirrer for 15 minutes at 50-55°C to obtain a clear and uniform solution; add 2.5g of zein to the above In the solution, magnetically stir again at 50-55° C. for 15 minutes until it becomes transparent to obtain a gelatin-zein electrospinning solution, which is marked as G / Z, and the electrospun film is recorded as a G / Z film. Add 50mg of perillaldehyde, thymol (abbreviated as T) and ε-polylysine (abbreviated as ε-PL) to 100ml G / Z solution respectively, and stir at 20-25°C for 24h to obtain 3 different static electricity The spinning solutions are marked as G / Z / P, G / Z / T and G / Z / ε-PL, respectively, and the membranes obtained after electrospinning are marked as G / Z / P, G / Z / T and G / Z, respectively / ε-PL film. Taking the G / Z film without adding antibacterial agent as the blank control, the effects of loading th...

Embodiment 2

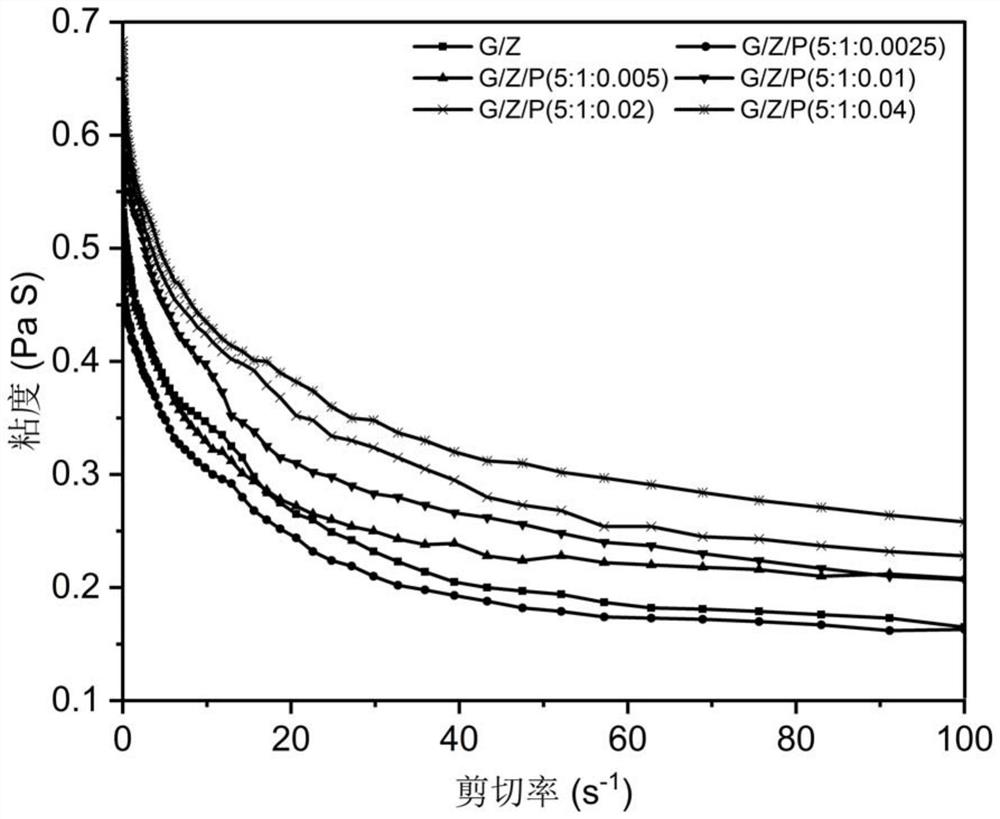

[0032] Embodiment 2 antibacterial nanofiber film

[0033] 1. Preparation of Antibacterial Nanofiber Membranes

[0034] Add 2.5g of gelatin to 20mL of 80% (volume percent) glacial acetic acid aqueous solution, stir in a water bath at 55°C for 0.5h to dissolve the gelatin, then add 0.5g of zein, stir for 8min to dissolve the zein The protein was dissolved and cooled to room temperature to obtain a gelatin-zein electrospinning solution. Using tween-80 as a solvent, prepare a 25% (mass percent concentration) perillaldehyde solution. The perillaldehyde solution was added to the gelatin-zein electrospinning liquid, and the electrospinning membrane blends with the perillaldehyde content of 62.5, 125, 250, 500, and 1000 μg / mL were prepared.

[0035] Use the DP30 electrospinning apparatus (Tianjin Yunfan Technology Co., Ltd.) to electrospin the electrospun membrane blends separately. The specific method is as follows: put the electrospun membrane blends into a 5ml syringe, and connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com