Stator potting type hydrogen circulating pump and manufacturing method thereof

A circulating pump and stator technology, which is applied to the stator potting type hydrogen circulating pump and its manufacturing field, can solve the problems of the overall structure of the motor is not compact enough, the wiring of the junction box is troublesome, the controller is set separately, etc., so as to solve the problem of hydrogen leakage and save energy. The effect of space and avoiding safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

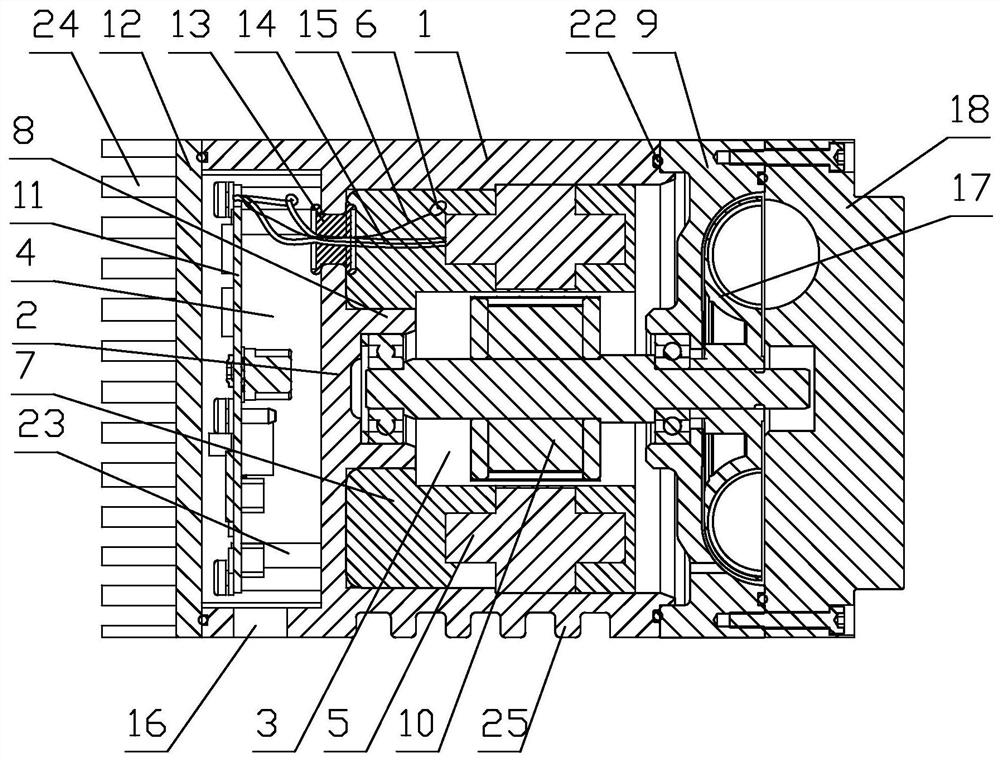

[0027] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

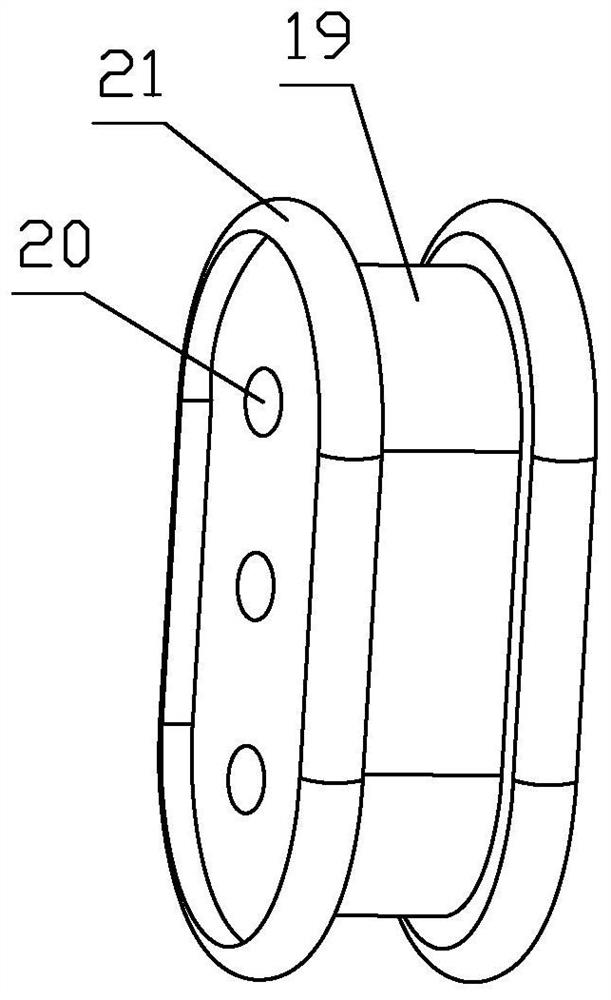

[0028] Such as Figure 1-2 As shown, a stator potting type hydrogen circulation pump, including:

[0029] The motor part, the motor part includes a housing 1, the housing 1 is provided with a partition 2, and the partition 2 separates the housing 1 into a motor cavity 3 and a controller cavity 4, and the motor cavity 3 is A stator 5 is installed, and a temperature sensor 6 is provided in the motor cavity 3, and the outer side of the stator 5 and the temperature sensor 6 is coated with a potting glue 7, which can not only improve the anti-corrosion performance of the rotor, but also improve the sealing performance , the side of the partition plate 2 near the motor cavity 3 is provided with a first bearing seat 8, and the side of the motor cavity 3 away fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com