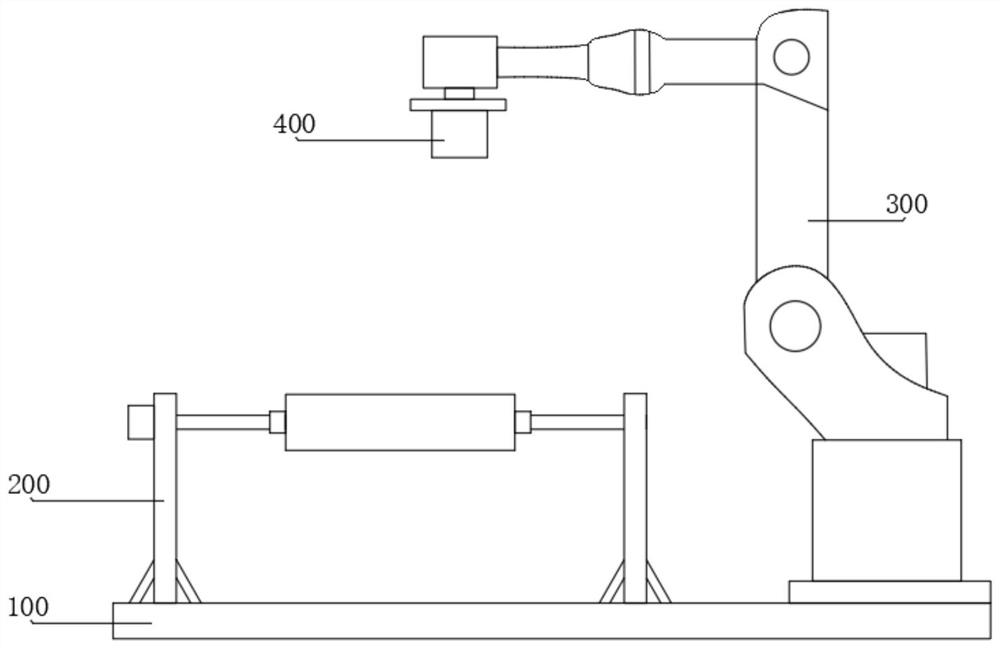

Three-dimensional scanning device based on laser triangulation method and scanning method

A technology of laser triangulation and three-dimensional scanning, which is applied to measuring devices, optical devices, instruments, etc., can solve the problems of inability to turn over the mold and poor scanning effect, and achieve the effect of easy scanning and collection and wide scanning range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

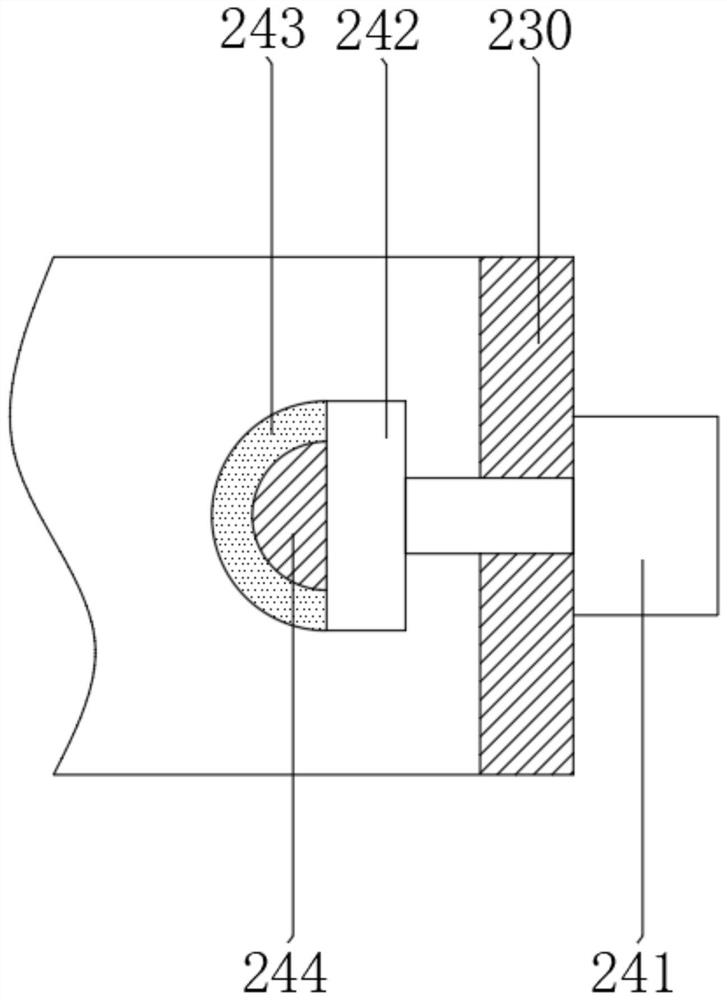

[0056] see Figure 7 , different from Embodiment 1, the solid part 240 includes a solid motor 245, a threaded rod 246, two solid plates 247 and several solid blocks 248, and the two solid plates 247 are slidably installed on the inner side of the support frame 230 , several solid material blocks 248 are respectively installed on the opposite side of the two solid material plates 247, the solid material motor 245 is installed on the side of the support frame 230, the threaded rod 246 is threadedly installed on the output end of the solid material motor 245, and the threaded rod 246 Two threaded sections 249 are arranged on the outer periphery of the two threaded sections 249, and the two threaded sections 249 are respectively threadedly connected with two solid material plates 247, and the thread directions of the two threaded sections 249 are opposite. When specifically arranged, the section of the solid material block 248 is semicircular Setting, the solid block 248 is set as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com