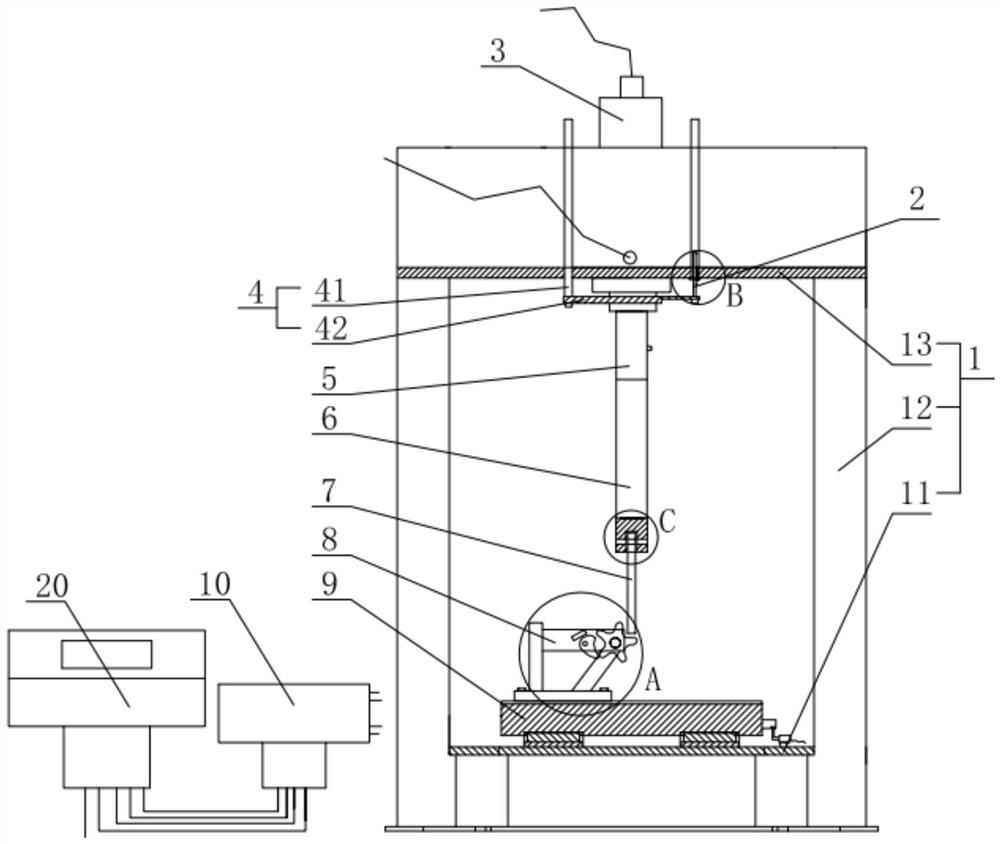

Static simulation test system and test method for anti-falling device of lifting protection platform

A technology of simulation test system and protective platform, which is applied in the direction of measurement device, mechanical component test, machine/structural component test, etc., and can solve the problems of test sample rack damage, unrealistic test, and uneven force on the anti-drop device. Achieve the effect of low test cost and expense, guarantee safety and reliability, convenient and reliable test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

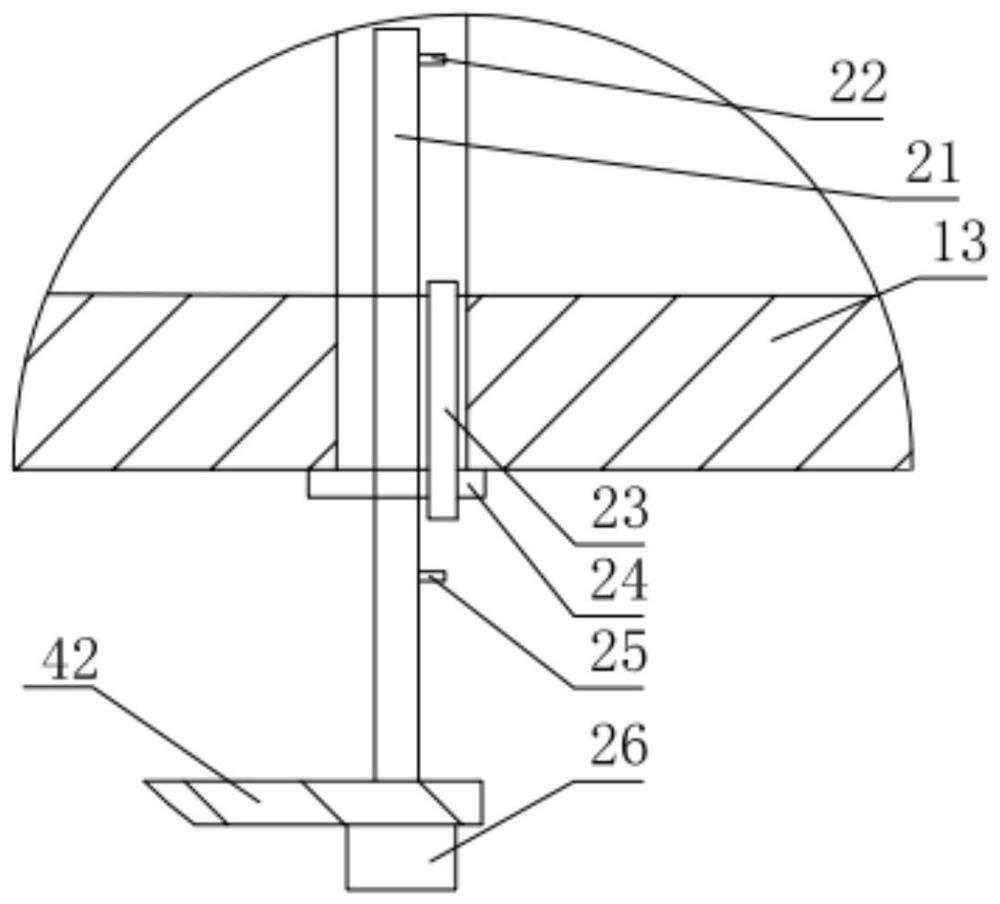

Embodiment 1

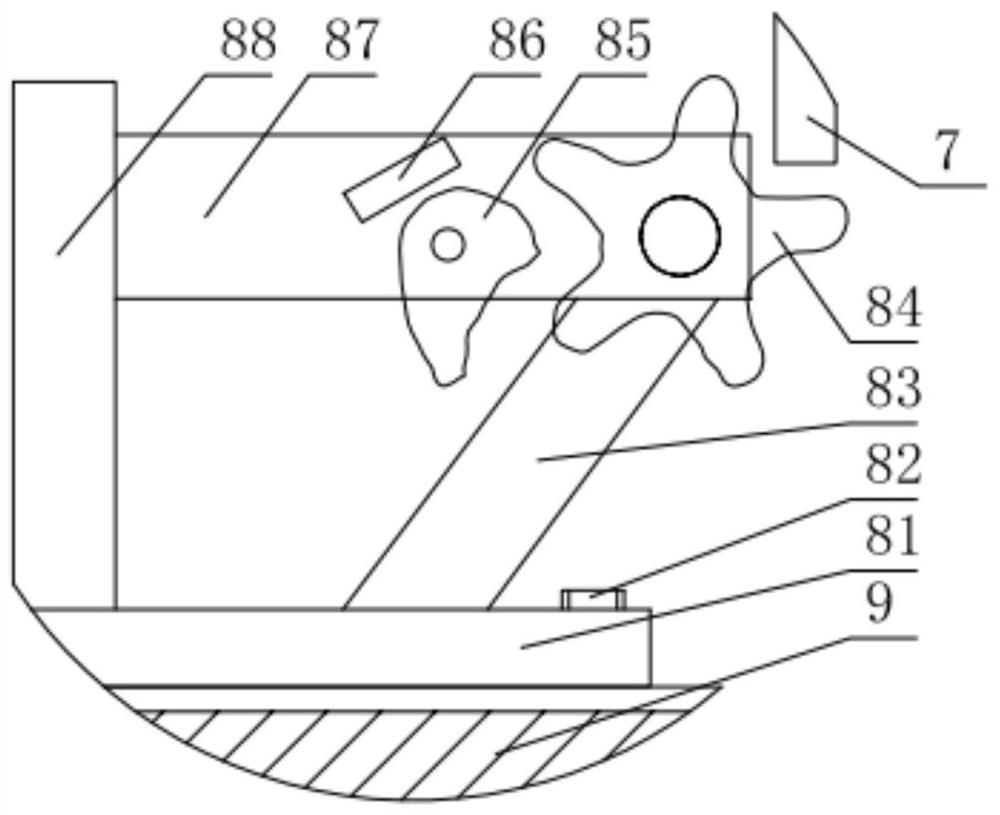

[0081] The movable roller 84 is the runner in the runner type anti-falling device; in the static simulation test, the brake block 85 and the baffle plate 86 are selected, and the pressure head 6 is driven downward in the lifting cylinder 3, and the force is exerted on the movable roller downward through the pressure plate 7. During the process of the roller 84, the static bearing capacity is obtained through the pressure sensor 5 by the failure of the movable roller 84.

Embodiment 2

[0083] Both the movable roller 84 and the brake block 85 are parts in the anti-falling device; in the static simulation test, the baffle plate 86 is selected, and the pressure head 6 is driven downward in the lifting cylinder 3, and the force is applied downward to the movable roller 84 through the pressure plate 7. During the process, due to the failure of the movable roller 84 or the brake block 85, its static bearing capacity is obtained through the pressure sensor 5.

[0084] The failure in this embodiment includes the occurrence of deformation, cracks, fractures and other states of the force-bearing or force-transmitting member.

[0085] The invention is convenient and reliable for testing, and has low cost and expense, which greatly contributes to the reliable and effective testing of the anti-falling device and helps to ensure the safety and reliability of the protection platform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com