Multichannel open-tube silica gel capillary column using a metal filament as template and a preparation method thereof

A capillary column and metal filament technology, applied in the field of chromatographic columns, can solve problems such as complex preparation methods, and achieve the effects of simple preparation methods, controllable channel morphology, and high column efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

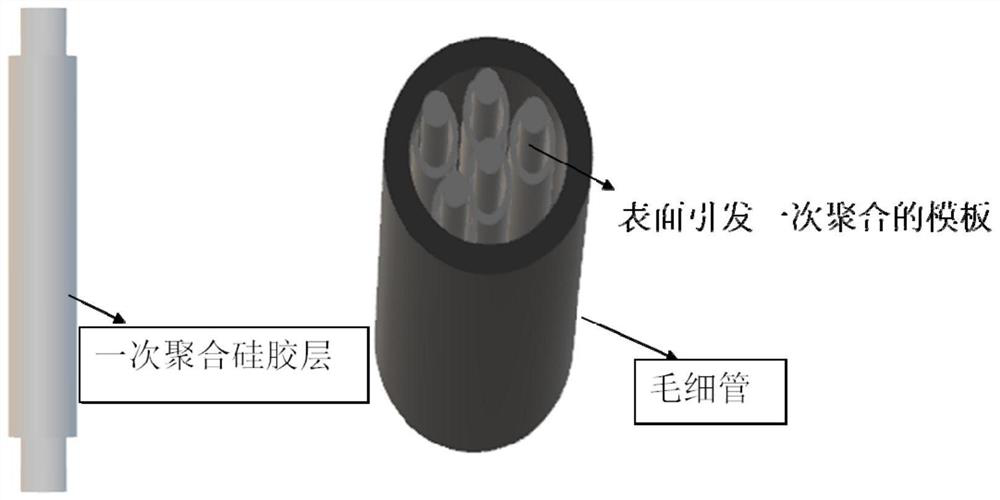

[0035] The first aspect of the present invention provides a method for preparing a multi-channel open-tube silica gel capillary column with metal filaments as a template, comprising the following steps: (1) performing primary polymerization through the sol solution in contact with the metal filaments, to A polymerized stationary phase layer is formed on the surface of the wire to obtain a metal wire with a stationary phase layer; (2) the metal wire with a stationary phase layer is introduced into the capillary, and secondary polymerization is initiated in the sol solution, and then aged by heating, Obtain a capillary column containing a silica gel stationary phase; (3) remove the metal wire in the capillary column by an in-situ dissolution method, and then obtain a multi-channel open-tube silica gel capillary column by calcining; wherein, in step (1), step (2) The sol solutions each contained polyethylene glycol, urea, methyl orthosilicate and acetic acid solutions.

[0036]Th...

Embodiment 1

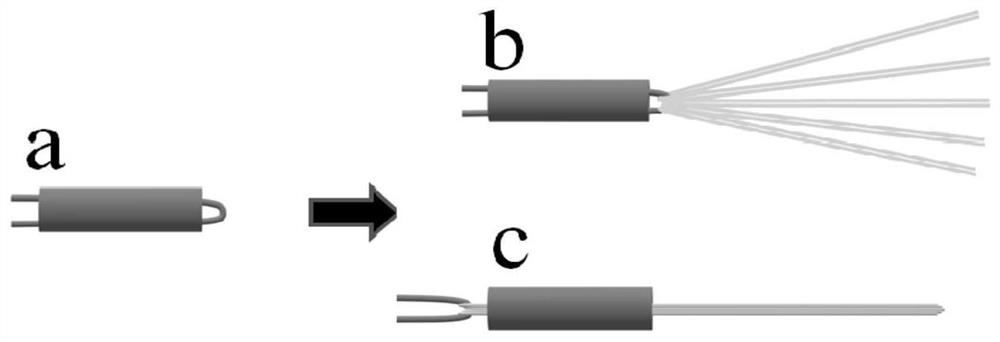

[0073] like figure 1 In the model, multiple copper wire templates are introduced into the capillary by a single metal wire pulling multiple metal wires. In a, a single metal wire is first introduced into the empty capillary, and in b and c, multiple metal wires are introduced into the capillary. Filament schematic. Preferably, the single metal filament is a 25 μm nickel-chromium wire.

Embodiment 2

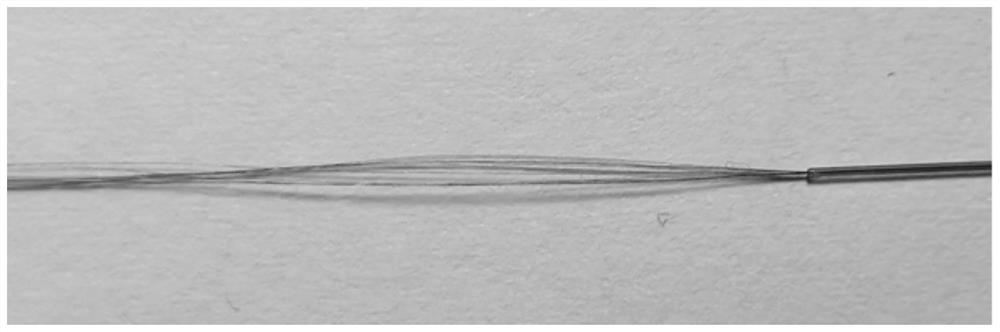

[0075] like figure 2 As shown, a single metal wire is used to pull multiple metal wires, and 10-14 copper filaments are introduced into a 100 μm capillary. die according to figure 2 introduced into the capillary as shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com