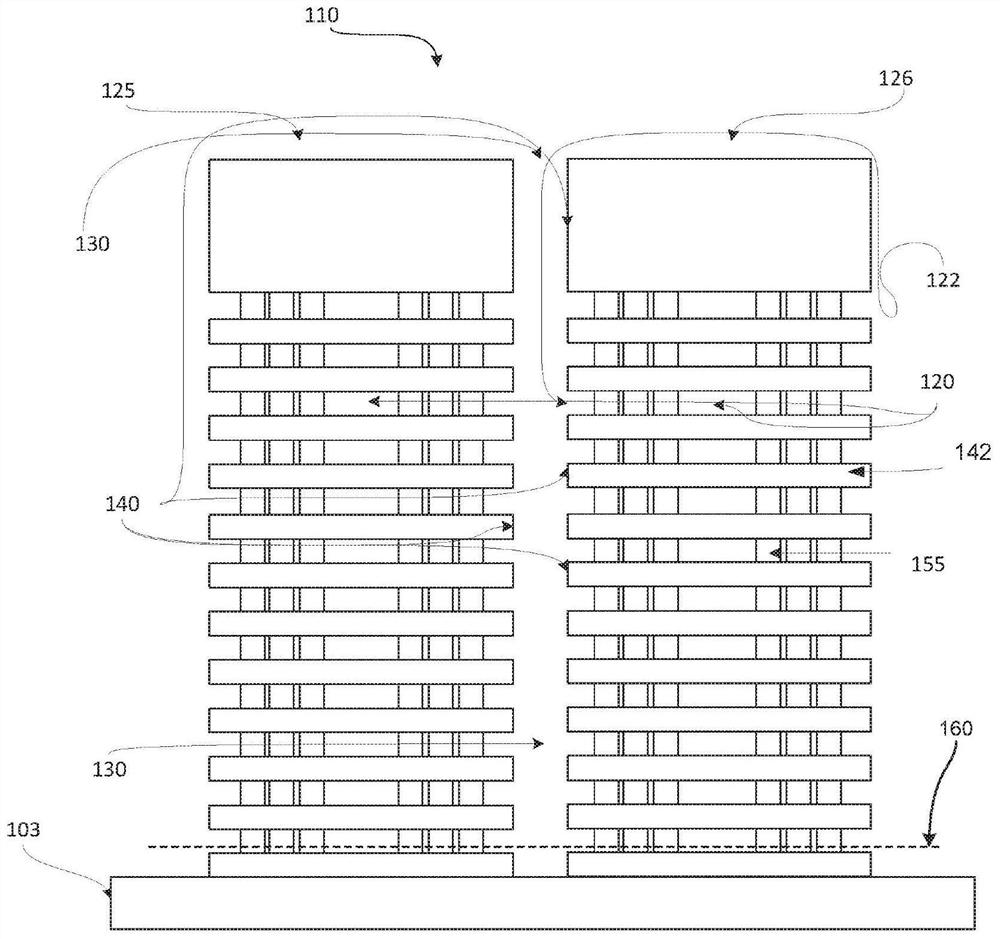

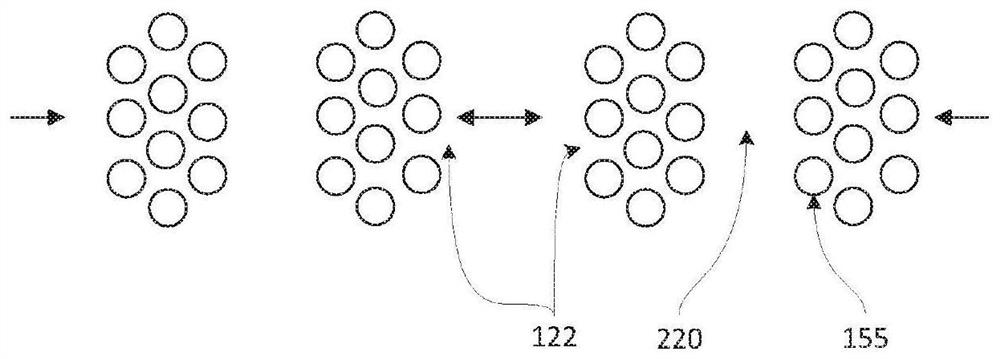

Atomic layer deposition on 3D NAND structures

A 3-D, deposition chamber technology, applied in the direction of semiconductor devices, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following description, numerous specific details are set forth in order to provide a thorough understanding of the presented embodiments. The disclosed embodiments may be practiced without some or all of these specific details. In other instances, well known process operations have not been described in detail to avoid unnecessarily obscuring the disclosed embodiments. While the disclosed embodiments will be described in conjunction with specific embodiments, it will be understood that they are not intended to be limiting of the disclosed embodiments.

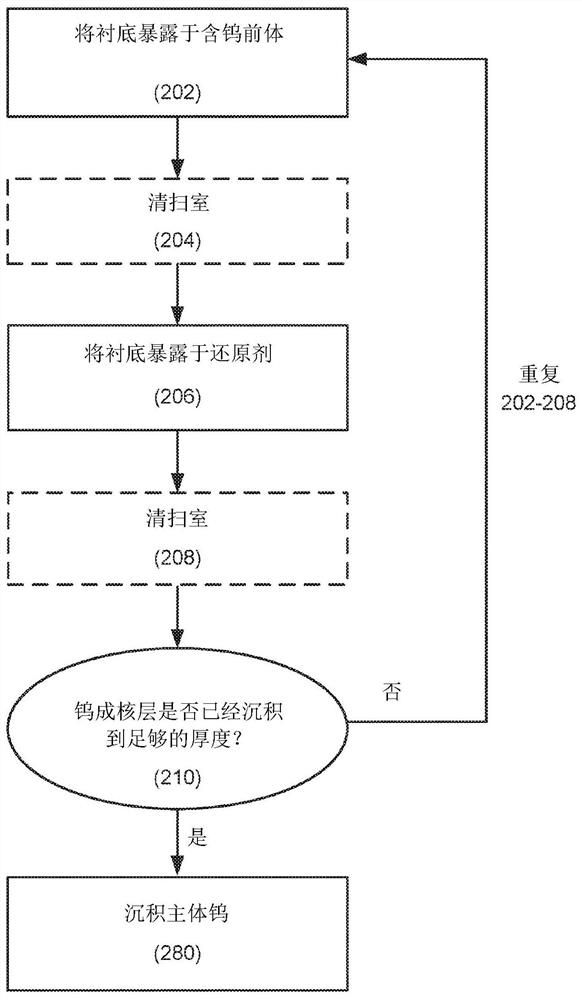

[0032] Tungsten (W) fills of features are often used in semiconductor device fabrication to form electrical contacts. In traditional methods of depositing tungsten films, a nucleating tungsten layer is first deposited into vias or contacts. Typically, the nucleation layer is a thin conformal layer that serves to facilitate the subsequent formation of the host material thereon. A tungsten nucleation layer can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com