Biomass raw material granulating and forming method

A technology of biomass raw materials and molding methods, which is applied in chemical instruments and methods, mold extrusion granulation, solid separation, etc. It can solve the problems that it is difficult to ensure the consistency of the molding particles, affect the health of the staff, and the particles are easy to pile up. , to achieve good sealing, easy protection, and reduce residue effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

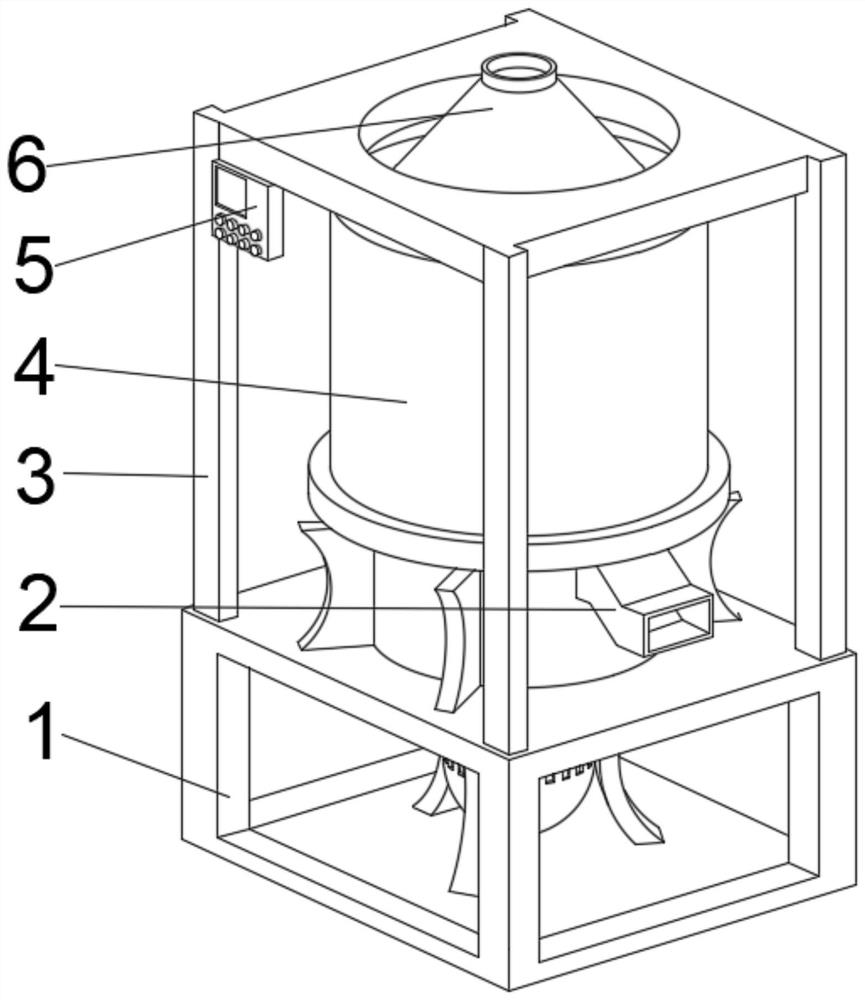

[0040] see Figure 1-6 , the present invention provides a technical solution: a biomass raw material granulation molding method, including a fixed base 1, a molding device 4 is provided at the middle of the top of the fixed base 1, and an outlet is connected to the bottom of the right outer wall of the molding device 4. The hopper 2 is provided with a feeder 6 in the middle of the top of the forming device 4, the top of the fixed base 1 is located on both sides of the forming device 4 and is fixedly connected with a connecting bracket 3, and the front top left side of the connecting bracket 3 is fixedly connected with a control panel 5.

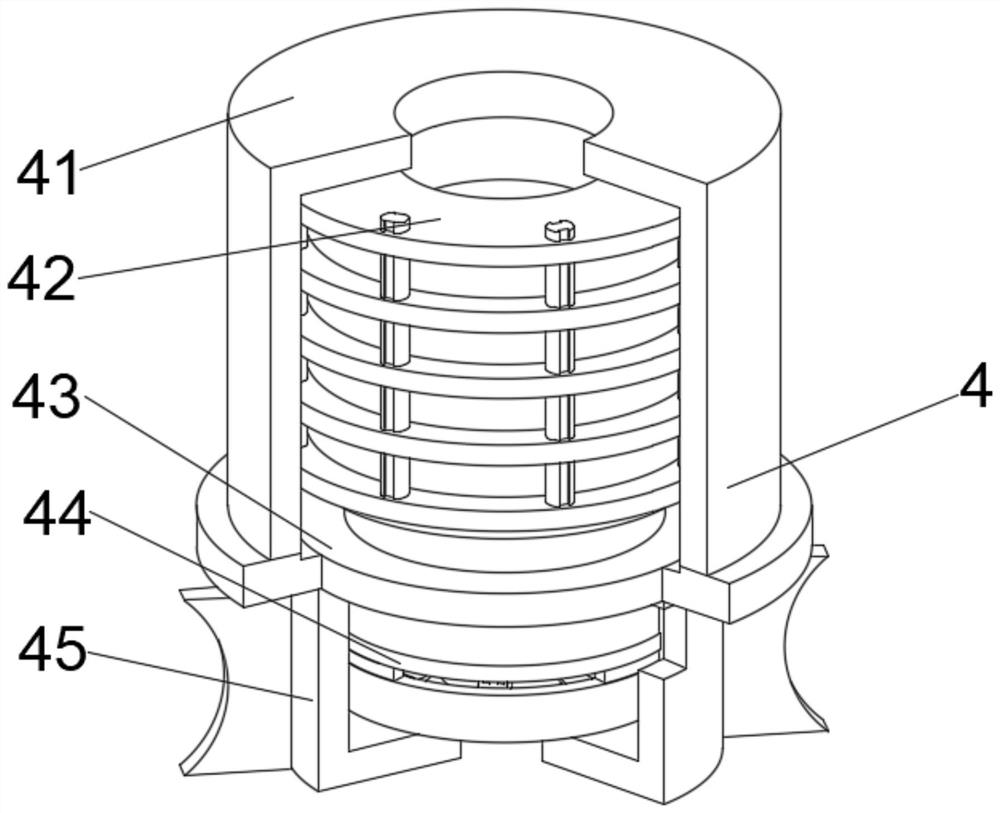

[0041] Wherein, the molding device 4 includes a granulation tube 41, a processing mechanism 42 is arranged at the top middle position of the inner cavity of the granulation tube 41, and a guide body 43 is fixedly connected to the bottom of the granulation tube 41, and the top middle position of the guide body 43 is connected to the processing...

Embodiment 2

[0047] see Figure 1-6 , on the basis of Embodiment 1, the present invention provides a technical solution: a method for granulating biomass raw materials, step 1: Fix the equipment, connect the fixed base 1 to the power supply, and connect the feeder 6 communicates with the molding device 4, and pours sufficient raw materials into the feeder 6;

[0048] Step 2: When preparing for processing, the raw materials are conveyed to the inside of the processing mechanism 42 through the granulating cylinder 41, and the processed materials are sent into the inside of the protection mechanism 44 by utilizing the connection between the processing mechanism 42 and the guide body 43 for centralized delivery;

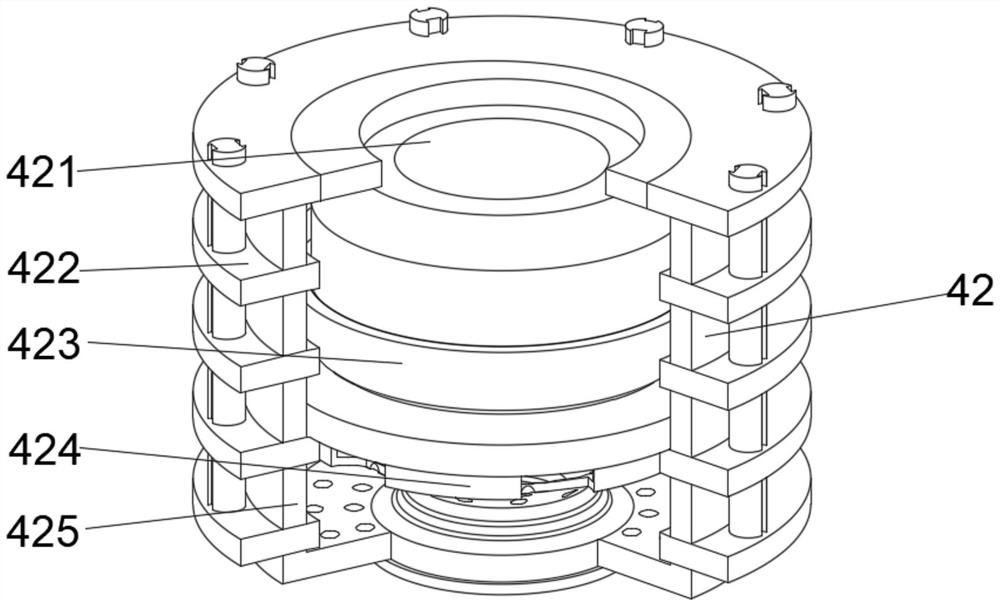

[0049] Step 3: When the raw material enters the equipment, connect the molded part 421 with the collection tray 423 to realize the rolling and falling of the formed particles, and use the screening cavity generated by the collection tray 423 and the conical screening body 424 to carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com