Anaerobic biogas biological desulfurization treatment device and method

A biological desulfurization and treatment device technology, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problem of low desulfurization removal rate, and achieve the effect of unattended management, maximum economic benefits, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

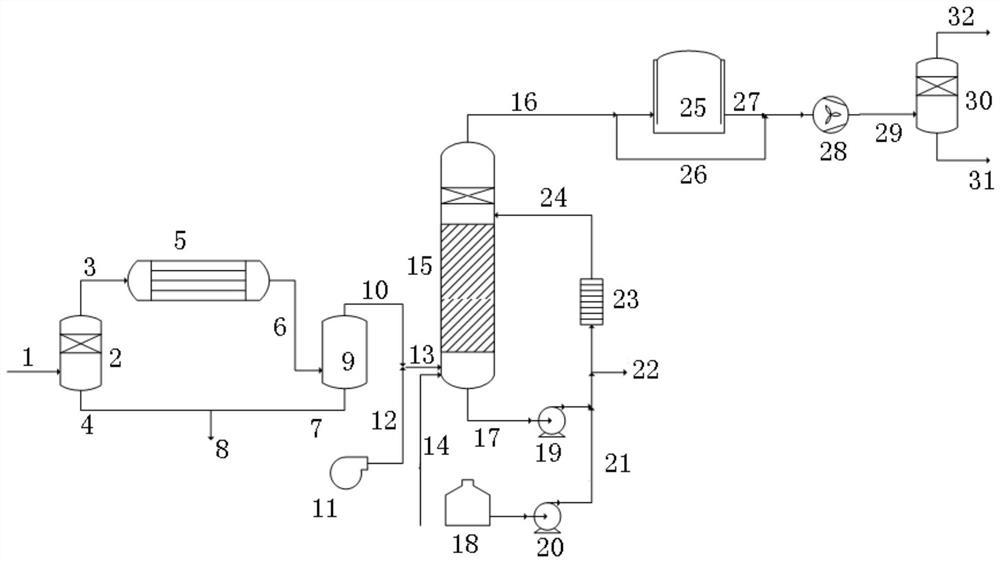

[0069] 55℃ high temperature anaerobic biogas at 1500m 3 / h rate enters as figure 1 The biogas biological desulfurization treatment device shown has a hydrogen sulfide concentration of 1200ppm. It is processed through the following steps:

[0070] (1) Cold dry system

[0071] The anaerobic biogas enters the coarse filter, and the water droplets and solid particles entrained in the anaerobic biogas are filtered out; the filtered biogas enters the tubular heat exchanger for heat exchange and cooling, and the outlet temperature of the tubular heat exchanger is controlled at 30°C;

[0072] The biogas after heat exchange enters the gas-liquid separator for gas-liquid separation, and the dehumidified biogas enters the desulfurization system for desulfurization treatment. The discharge flow rate of the drain pipe is 136kg / h.

[0073] (2) Biological desulfurization system

[0074] The dehumidified biogas is mixed with fresh air and enters the biological desulfurization system for ...

Embodiment 2

[0078] 55℃ high temperature anaerobic biogas at 550m 3 / h rate enters as figure 1 The biogas biological desulfurization treatment device shown has a hydrogen sulfide concentration of 2500ppm. It is processed through the following steps:

[0079] (1) Cold dry system

[0080] The anaerobic biogas enters the coarse filter, and the water droplets and solid particles entrained in the anaerobic biogas are filtered out; the filtered biogas enters the tubular heat exchanger for heat exchange and cooling, and the outlet temperature of the tubular heat exchanger is controlled at 22°C;

[0081] The biogas after heat exchange enters the gas-liquid separator for gas-liquid separation, and the dehumidified biogas enters the desulfurization system for desulfurization treatment. The discharge flow rate of the discharge pipe is 52kg / h.

[0082] (2) Biological desulfurization system

[0083] The dehumidified biogas is mixed with fresh air and enters the biological desulfurization system fo...

Embodiment 3

[0087] 50℃ high temperature anaerobic biogas at 1800m 3 / h rate enters as figure 1 The biogas biological desulfurization treatment device shown has a hydrogen sulfide concentration of 1500ppm. It is processed through the following steps:

[0088] (1) Cold dry system

[0089] The anaerobic biogas enters the coarse filter to filter out the water droplets and solid particles entrained in the anaerobic biogas; the filtered biogas enters the tubular heat exchanger for heat exchange and cooling, and the outlet temperature of the tubular heat exchanger is controlled to 32°C;

[0090] The biogas after heat exchange enters the gas-liquid separator for gas-liquid separation, and the dehumidified biogas enters the desulfurization system for desulfurization treatment. The discharge flow rate of the discharge pipe is 160kg / h.

[0091] (2) Biological desulfurization system

[0092] The dehumidified biogas is mixed with fresh air and enters the biological desulfurization system for desu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com